250-222 Wedge Type Lathe Tool Post

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Lathe Wedge Type Tool Post

Lathe Tool Holder Post Title:

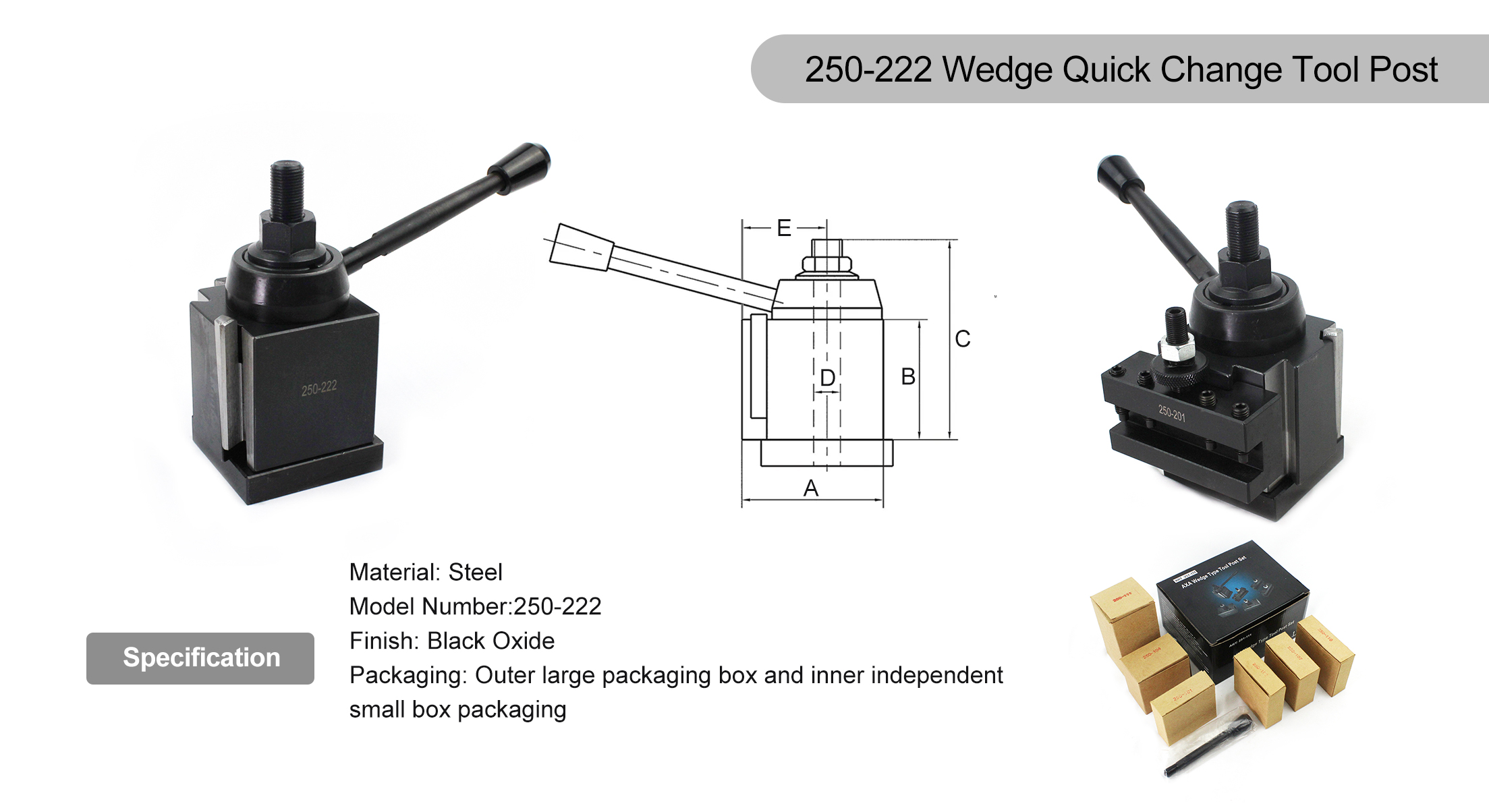

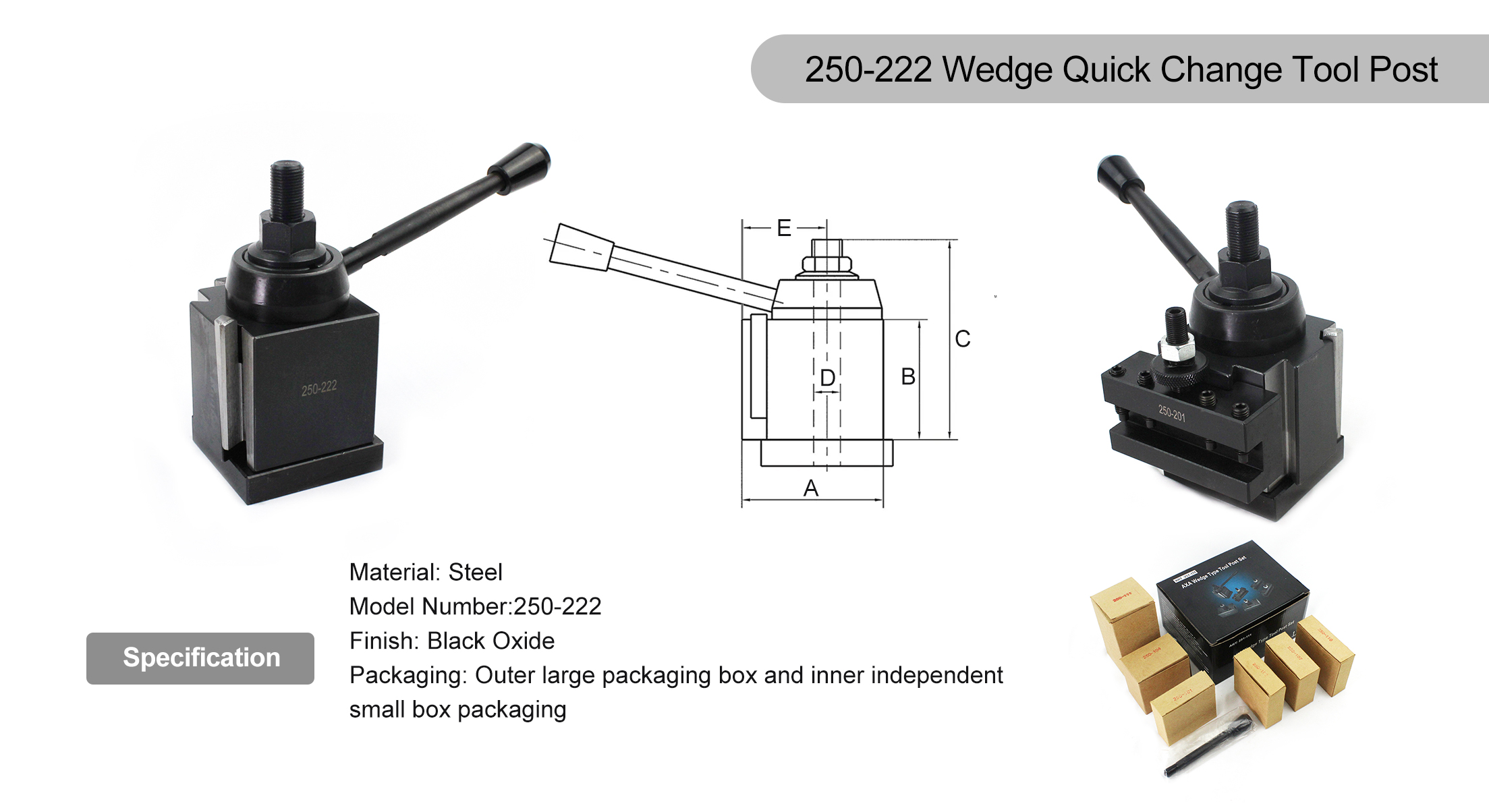

High Quality 250-222 tool post lathe wedge quick change tool post Black oxide Finish

The 250-222 Quick Change Tool Post Holder is known for its high rigidity wedge locking, fast tool changing, and repeatable positioning accuracy, making it suitable for stable and efficient machining of various processes such as outer circles, end faces, slotting, cutting, drilling/boring, etc. Used for fitting with the center rod/sleeve of the machine tool, actual accessories shall prevail.

Specification:

250-222 Wedge Lathe Quick Change Tool Post

Wedge-Type tool post (3"Lx3"Wx4-5/8"H)

Compatible model: 250-222 standard tool holder series

Swing (Inch):10-15inch

Structural characteristics and advantages:

Wedge locking mechanism: By pushing the tool holder with a wedge block, a strong and uniform clamping force is achieved. It has high rigidity and good vibration resistance, which is conducive to suppressing chatter and improving surface quality and tool life.

Quick replacement and high repetition positioning: With fewer tool changing steps and shorter time, it has excellent repetition positioning accuracy and is suitable for frequent switching and rhythmic production in multiple processes.

Materials and Heat Treatment: The tool holder body and key moving parts are usually made of alloy tool steel, which is quenched and tempered+precision ground, with high hardness, good wear resistance, and stable size and shape.

| Specs | Lathe Swing (In.) | A | B | |||

| Model | Inch | mm | Inch | mm | Inch | mm |

| 250-111 | 12 | 304 | 2 1/2 | 63.5 | 2 1/4 | 57.15 |

| 250-222 | 10-15 | 254-381 | 3 | 76.2 | 2 3/4 | 69.85 |

| 250-333 | 13-18 | 330-457 | 3 1/2 | 88.9 | 3 | 76.2 |

| 250-444 | 14-20 | 355-508 | 4 | 101.6 | 3 5/8 | 92.075 |

| 250-555 | 17-48 | 432-1219 | 5 | 127 | 4 5/8 | 117.47 |

| Specs | C | D | E | Holder Code | Order No. | ||

| Model | Inch | mm | Inch | mm | |||

| 250-111 | 3 7/8 | 98.425 | M14 x 1.5 | 1 3/8 | 34.925 | 250-1XX | 2500-1111 |

| 250-222 | 4 3/8 | 111.125 | M16 x 1.5 | 1 9/16 | 39.68 | 250-2XX | 2500-2222 |

| 250-333 | 4 7/8 | 123.825 | M20 x 2 | 1 29/32 | 48.42 | 250-3XX | 2500-3333 |

| 250-444 | 6 | 152.4 | M22 x 2 | 2 1/8 | 53.975 | 250-4XX | 2500-4444 |

| 250-555 | 7 3/8 | 187.32 | M24 x 2 | 2 11/16 | 68.26 | 250-5XX | 2500-5555 |

Installation adaptability:

Some sets come with or require the use of T-shaped nut plates, which require slight planing/machining according to the T-shaped groove of the machine tool to achieve optimal fit, rigidity, and repeated positioning;

Installation prompt:

Use machine tools with random wrenches and appropriate torque specifications to avoid deformation or loss of accuracy caused by overtightening.

If equipped with a T-shaped nut plate, necessary repairs should be made according to the size of the T-shaped groove on the machine tool; After installation, check the locking force, blade tip height, and repeat positioning.

Features of Lathe Wedge Type Tool Post

Lathe Tool Holder Post Title:

High Quality 250-222 tool post lathe wedge quick change tool post Black oxide Finish

The 250-222 Quick Change Tool Post Holder is known for its high rigidity wedge locking, fast tool changing, and repeatable positioning accuracy, making it suitable for stable and efficient machining of various processes such as outer circles, end faces, slotting, cutting, drilling/boring, etc. Used for fitting with the center rod/sleeve of the machine tool, actual accessories shall prevail.

Specification:

250-222 Wedge Lathe Quick Change Tool Post

Wedge-Type tool post (3"Lx3"Wx4-5/8"H)

Compatible model: 250-222 standard tool holder series

Swing (Inch):10-15inch

Structural characteristics and advantages:

Wedge locking mechanism: By pushing the tool holder with a wedge block, a strong and uniform clamping force is achieved. It has high rigidity and good vibration resistance, which is conducive to suppressing chatter and improving surface quality and tool life.

Quick replacement and high repetition positioning: With fewer tool changing steps and shorter time, it has excellent repetition positioning accuracy and is suitable for frequent switching and rhythmic production in multiple processes.

Materials and Heat Treatment: The tool holder body and key moving parts are usually made of alloy tool steel, which is quenched and tempered+precision ground, with high hardness, good wear resistance, and stable size and shape.

| Specs | Lathe Swing (In.) | A | B | |||

| Model | Inch | mm | Inch | mm | Inch | mm |

| 250-111 | 12 | 304 | 2 1/2 | 63.5 | 2 1/4 | 57.15 |

| 250-222 | 10-15 | 254-381 | 3 | 76.2 | 2 3/4 | 69.85 |

| 250-333 | 13-18 | 330-457 | 3 1/2 | 88.9 | 3 | 76.2 |

| 250-444 | 14-20 | 355-508 | 4 | 101.6 | 3 5/8 | 92.075 |

| 250-555 | 17-48 | 432-1219 | 5 | 127 | 4 5/8 | 117.47 |

| Specs | C | D | E | Holder Code | Order No. | ||

| Model | Inch | mm | Inch | mm | |||

| 250-111 | 3 7/8 | 98.425 | M14 x 1.5 | 1 3/8 | 34.925 | 250-1XX | 2500-1111 |

| 250-222 | 4 3/8 | 111.125 | M16 x 1.5 | 1 9/16 | 39.68 | 250-2XX | 2500-2222 |

| 250-333 | 4 7/8 | 123.825 | M20 x 2 | 1 29/32 | 48.42 | 250-3XX | 2500-3333 |

| 250-444 | 6 | 152.4 | M22 x 2 | 2 1/8 | 53.975 | 250-4XX | 2500-4444 |

| 250-555 | 7 3/8 | 187.32 | M24 x 2 | 2 11/16 | 68.26 | 250-5XX | 2500-5555 |

Installation adaptability:

Some sets come with or require the use of T-shaped nut plates, which require slight planing/machining according to the T-shaped groove of the machine tool to achieve optimal fit, rigidity, and repeated positioning;

Installation prompt:

Use machine tools with random wrenches and appropriate torque specifications to avoid deformation or loss of accuracy caused by overtightening.

If equipped with a T-shaped nut plate, necessary repairs should be made according to the size of the T-shaped groove on the machine tool; After installation, check the locking force, blade tip height, and repeat positioning.

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>