Captive Screws

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Captive Screws

Captive Knurled Screw Title:

Good quality captive screw socket head captive panel screws stainless steel a2-70 a4 for fastening

Pan Head Cross Captive Screw A4-70 Specifications:

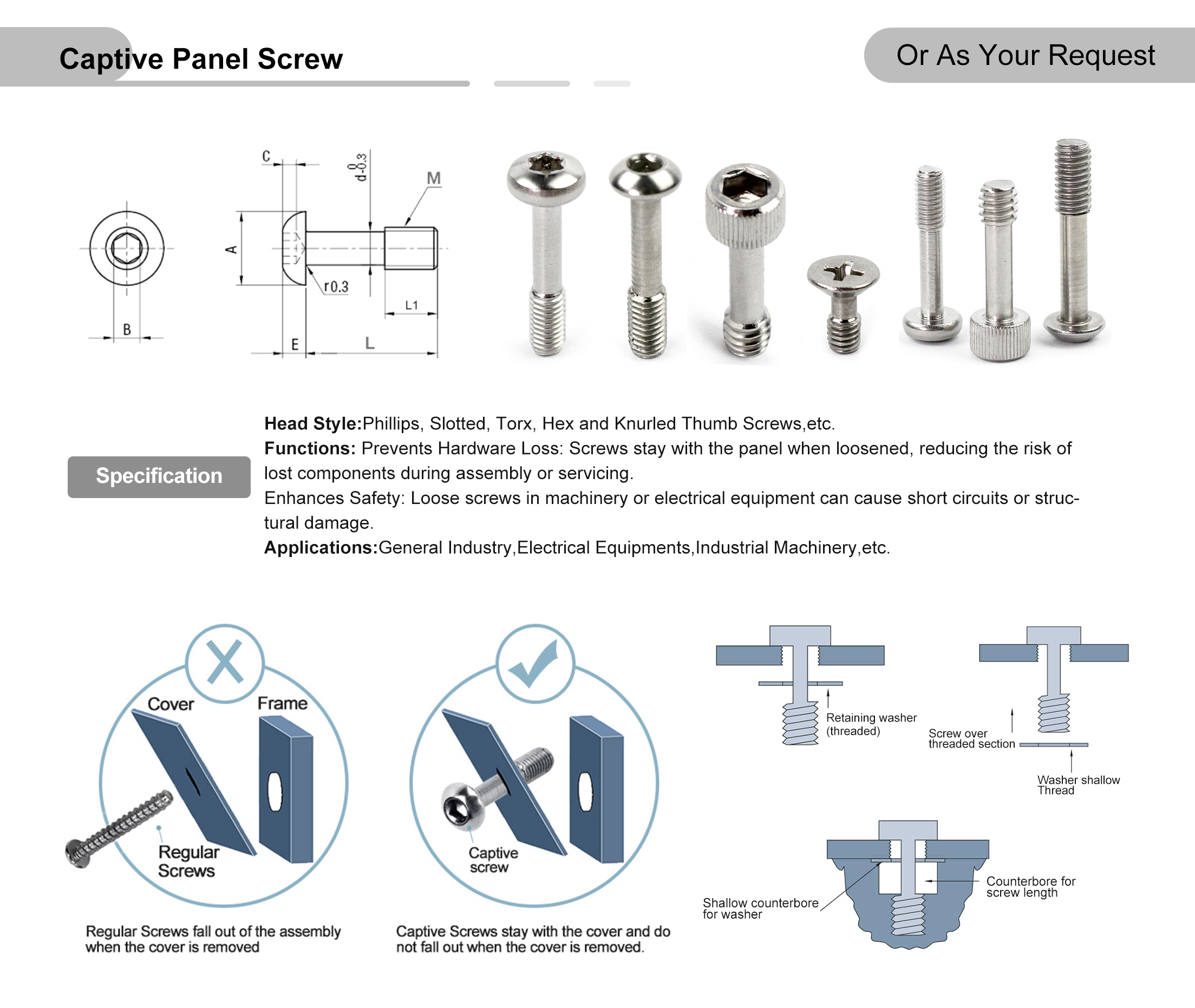

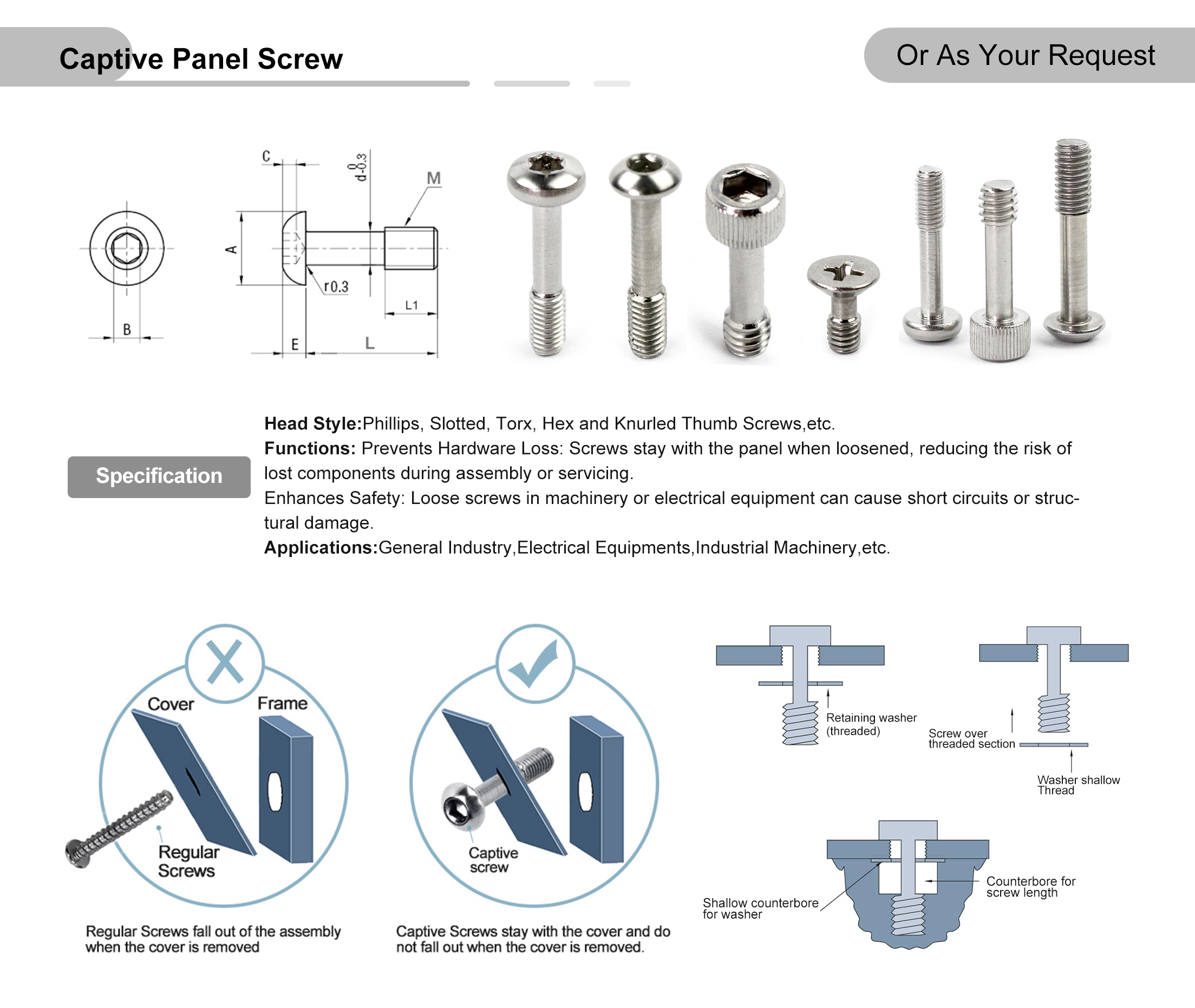

The key difference between Captive locating screws and regular screws is that regular screws will completely detach from the installation parts after disassembly, while Captive screws always maintain a connected state with the installation panel, chassis, or parts through their own structure (such as steps, snap springs, flower teeth) or matching components (such as gaskets, buckles).

Common Materials: stainless steel (304/316), carbon steel (low-carbon steel/Q235), aluminum alloy, copper alloy;

Cold Heading Forming

Core process: The wire is pressed into the basic shape of the screw head and rod through a cold heading machine, including special structures such as steps and slots. Compared with cutting processing, cold heading can preserve the continuity of metal fibers and improve the strength of screws.

Thread Machining

Using the rolling process (mass production) or turning process (customized parts) to process threads, the rolling thread has high precision and good strength, suitable for standard specification capstive screws.

Special Structural Processing

Slot machining: machining annular grooves on the shaft by turning or milling;

Flower tooth/rivet tooth processing: formed by rolling or milling with specialized molds;

Spring assembly: Insert the customized spring into the rod and fix it with a snap spring or step.

Surface Treatment

Rust and anti-corrosion treatment: Carbon steel screws are usually treated with galvanizing, color galvanizing, and blackening; Stainless steel screws can be passivated; Aluminum alloy screws can be anodized; Aviation screws will undergo high-end treatments such as cadmium plating and titanium plating.

Quality Inspection

Testing items: dimensional accuracy (step diameter, slot depth, thread specifications), tensile strength, anti detachment performance, corrosion resistance;

Testing tools: caliper, thread gauge, tensile testing machine, salt spray testing machine.

| M | L | L1 | A | E(Max.) | B | C(Min.) | d |

| M3 | 8 10 12 15 20 | 4 | 5.5 | 1.6 | 2 | 1.04 | 2.2 |

| M4 | 10 12 15 20 | 5 | 7.5 | 2.2 | 2.5 | 1.3 | 3 |

| M5 | 12 15 20 25 | 6 | 9.5 | 2.7 | 3 | 1.56 | 3.9 |

| M6 | 12 15 20 25 | 8 | 10.5 | 3.3 | 4 | 2.08 | 4.5 |

| M8 | 12 15 20 25 | 10 | 14 | 4.4 | 5 | 2.6 | 6.3 |

Application:

Electronic and Electrical: server chassis, industrial computer panel, UPS power supply housing;

Mechanical Equipment: engineering machinery cab, CNC machine tool protective cover;

Aerospace: aircraft interior panels, satellite equipment connectors;

Rail Transit: interior of high-speed rail carriages, subway equipment cabinets;

Medical Equipment: diagnostic equipment casing, surgical instrument fasteners.

Features and Advantages

Anti detachment and anti loss: After disassembly, the screws are still connected to the base to avoid loss during equipment maintenance and transportation, especially suitable for high-altitude operations and narrow space assembly scenarios.

Simplify assembly process: No need to store and pick up screws separately, improve production line assembly efficiency, and reduce labor costs.

Improve connection stability: Special structural designs (such as snap springs and steps) can effectively resist vibration impact, prevent screw loosening, and are suitable for high vibration conditions.

Suitable for frequent disassembly and assembly scenarios: Repeated disassembly and assembly will not damage the accuracy of the screw and installation hole fit, extending the product's service life.

Features of Captive Screws

Captive Knurled Screw Title:

Good quality captive screw socket head captive panel screws stainless steel a2-70 a4 for fastening

Pan Head Cross Captive Screw A4-70 Specifications:

The key difference between Captive locating screws and regular screws is that regular screws will completely detach from the installation parts after disassembly, while Captive screws always maintain a connected state with the installation panel, chassis, or parts through their own structure (such as steps, snap springs, flower teeth) or matching components (such as gaskets, buckles).

Common Materials: stainless steel (304/316), carbon steel (low-carbon steel/Q235), aluminum alloy, copper alloy;

Cold Heading Forming

Core process: The wire is pressed into the basic shape of the screw head and rod through a cold heading machine, including special structures such as steps and slots. Compared with cutting processing, cold heading can preserve the continuity of metal fibers and improve the strength of screws.

Thread Machining

Using the rolling process (mass production) or turning process (customized parts) to process threads, the rolling thread has high precision and good strength, suitable for standard specification capstive screws.

Special Structural Processing

Slot machining: machining annular grooves on the shaft by turning or milling;

Flower tooth/rivet tooth processing: formed by rolling or milling with specialized molds;

Spring assembly: Insert the customized spring into the rod and fix it with a snap spring or step.

Surface Treatment

Rust and anti-corrosion treatment: Carbon steel screws are usually treated with galvanizing, color galvanizing, and blackening; Stainless steel screws can be passivated; Aluminum alloy screws can be anodized; Aviation screws will undergo high-end treatments such as cadmium plating and titanium plating.

Quality Inspection

Testing items: dimensional accuracy (step diameter, slot depth, thread specifications), tensile strength, anti detachment performance, corrosion resistance;

Testing tools: caliper, thread gauge, tensile testing machine, salt spray testing machine.

| M | L | L1 | A | E(Max.) | B | C(Min.) | d |

| M3 | 8 10 12 15 20 | 4 | 5.5 | 1.6 | 2 | 1.04 | 2.2 |

| M4 | 10 12 15 20 | 5 | 7.5 | 2.2 | 2.5 | 1.3 | 3 |

| M5 | 12 15 20 25 | 6 | 9.5 | 2.7 | 3 | 1.56 | 3.9 |

| M6 | 12 15 20 25 | 8 | 10.5 | 3.3 | 4 | 2.08 | 4.5 |

| M8 | 12 15 20 25 | 10 | 14 | 4.4 | 5 | 2.6 | 6.3 |

Application:

Electronic and Electrical: server chassis, industrial computer panel, UPS power supply housing;

Mechanical Equipment: engineering machinery cab, CNC machine tool protective cover;

Aerospace: aircraft interior panels, satellite equipment connectors;

Rail Transit: interior of high-speed rail carriages, subway equipment cabinets;

Medical Equipment: diagnostic equipment casing, surgical instrument fasteners.

Features and Advantages

Anti detachment and anti loss: After disassembly, the screws are still connected to the base to avoid loss during equipment maintenance and transportation, especially suitable for high-altitude operations and narrow space assembly scenarios.

Simplify assembly process: No need to store and pick up screws separately, improve production line assembly efficiency, and reduce labor costs.

Improve connection stability: Special structural designs (such as snap springs and steps) can effectively resist vibration impact, prevent screw loosening, and are suitable for high vibration conditions.

Suitable for frequent disassembly and assembly scenarios: Repeated disassembly and assembly will not damage the accuracy of the screw and installation hole fit, extending the product's service life.

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>