Ceiling Anchors

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Ceiling Anchors

Ceiling anchor mount anchorTitle:

Heavy duty drop in expansion anchor zinc coating concrete ceiling anchor bolt

Wedge-shaped expansion anchor bolt

Carbon steel material+galvanized/passivated treatment, diameter covering M6-M30, length 40-260mm standard specification;

By hammering, the wedge-shaped sleeve is expanded to form a mechanical locking structure;

Inner sleeve anchor bolt

The hexagonal head design complies with ASTM A325 standard;

The internal expansion mechanism is applicable to thin concrete substrates;

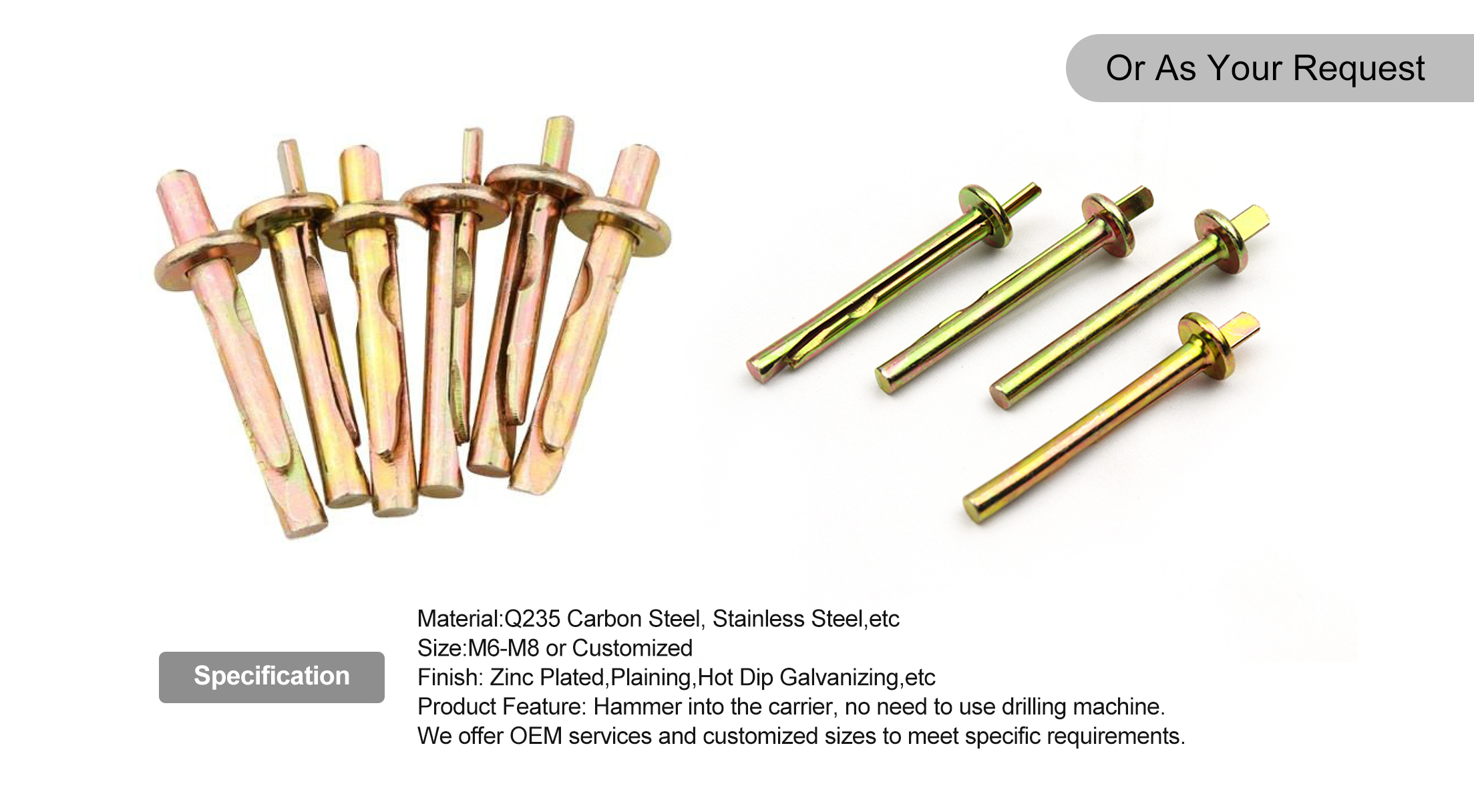

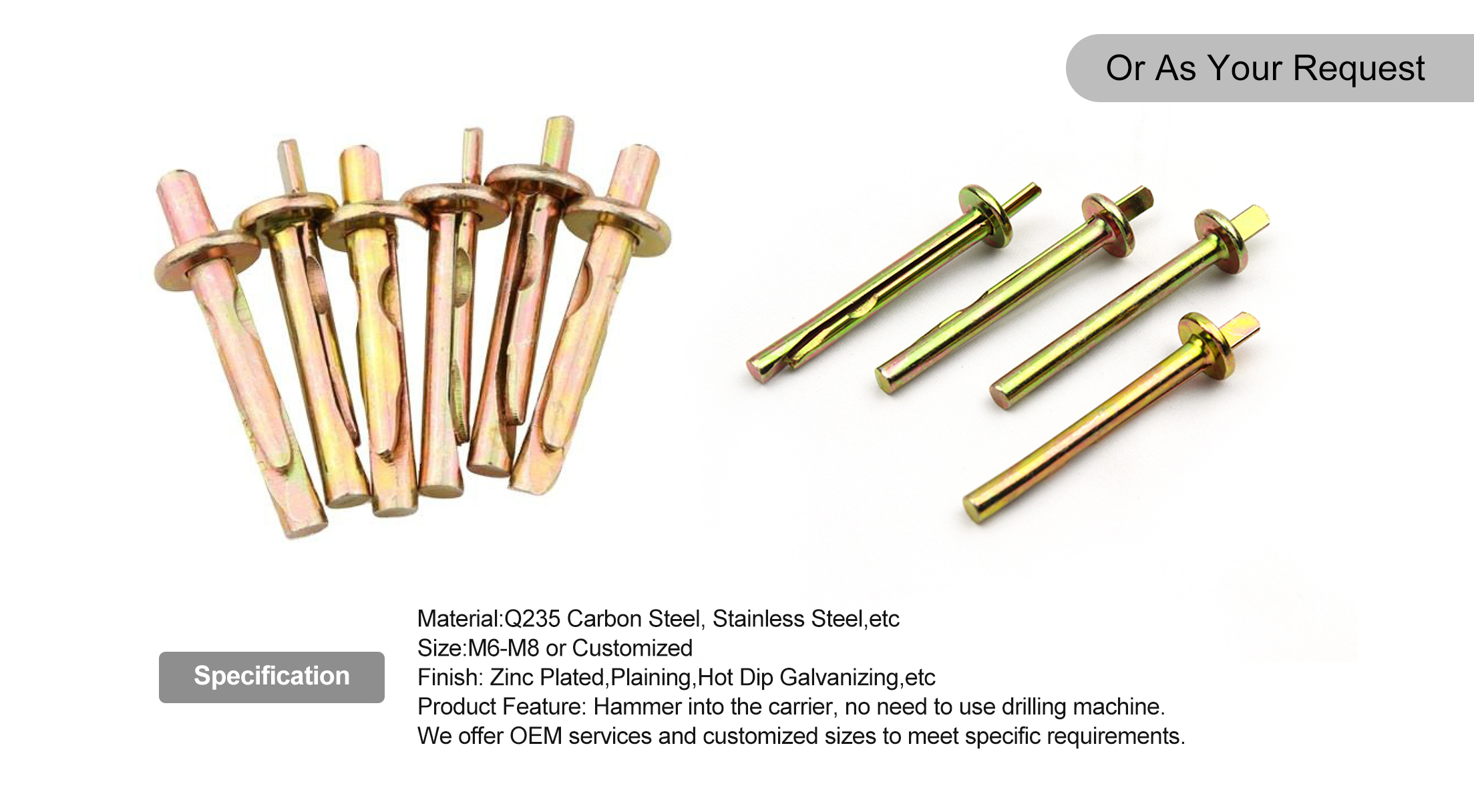

Strike in anchor bolt

Yellow zinc coating anti-corrosion, pre assembly design for quick installation by a single person;

Material:Q235 Carbon Steel, Stainless Steel,etc

Size:M6-M8 or Customized

Finish: Zinc Plated,Plaining,Hot Dip Galvanizing,etc

Product Feature: Hammer into the carrier, no need to use drilling machine.

We offer OEM services and customized sizes to meet specific requirements.

| Item | Ceiling Anchor Bolt |

| Size | M6-M8 or Customized |

| Material | Q235 Carbon Steel,Stainless Steel,etc |

| Surface Treatment | Plaining,Zinc Coating,Hot Dip Galvanizing,etc |

| Product Feature | Hammer into the carrier, no need to use drilling machine |

| Application | Concrete, light concrete, solid brick,sandy limestone, etc. |

Application:

Heavy industrial scenario - chemical pipeline suspension system, connection nodes between steel structure and concrete roof of factory building;

In the field of architecture, the invisible fixing system for curtain wall keel and the inverted fixing scheme for seismic brackets;

Installation steps

Drilling: Select the appropriate drill bit based on the diameter of the anchor bolt, mark the installation position on the concrete ceiling, and then proceed with drilling.

Cleaning the borehole: After drilling, use a compressed air gun or specialized borehole cleaning tool to thoroughly clean the dust and debris inside the borehole.

Installation of anchor bolts: Place the ceiling anchor bolts into the borehole. For anchor bolts with expansion sleeves, ensure that the expansion sleeve is installed correctly and tightly with the anchor bolt body. Then, install the object that needs to be fixed through the threaded end of the anchor bolt, and fit it with a washer and nut. For heavier objects, larger sized washers and nuts may be required to increase the load-bearing area and distribute the pressure of the object on the anchor bolt.

Tighten anchor bolt: Use a wrench or power tool to tighten the nut to the specified torque value. Different specifications of anchor bolts have corresponding recommended torque values. During the tightening process, attention should be paid to uniform force to avoid damage to the anchor bolts or cracking of the concrete due to excessive torque. If the torque is too small, the anchor bolts will not be firmly fixed.

Features of Ceiling Anchors

Ceiling anchor mount anchorTitle:

Heavy duty drop in expansion anchor zinc coating concrete ceiling anchor bolt

Wedge-shaped expansion anchor bolt

Carbon steel material+galvanized/passivated treatment, diameter covering M6-M30, length 40-260mm standard specification;

By hammering, the wedge-shaped sleeve is expanded to form a mechanical locking structure;

Inner sleeve anchor bolt

The hexagonal head design complies with ASTM A325 standard;

The internal expansion mechanism is applicable to thin concrete substrates;

Strike in anchor bolt

Yellow zinc coating anti-corrosion, pre assembly design for quick installation by a single person;

Material:Q235 Carbon Steel, Stainless Steel,etc

Size:M6-M8 or Customized

Finish: Zinc Plated,Plaining,Hot Dip Galvanizing,etc

Product Feature: Hammer into the carrier, no need to use drilling machine.

We offer OEM services and customized sizes to meet specific requirements.

| Item | Ceiling Anchor Bolt |

| Size | M6-M8 or Customized |

| Material | Q235 Carbon Steel,Stainless Steel,etc |

| Surface Treatment | Plaining,Zinc Coating,Hot Dip Galvanizing,etc |

| Product Feature | Hammer into the carrier, no need to use drilling machine |

| Application | Concrete, light concrete, solid brick,sandy limestone, etc. |

Application:

Heavy industrial scenario - chemical pipeline suspension system, connection nodes between steel structure and concrete roof of factory building;

In the field of architecture, the invisible fixing system for curtain wall keel and the inverted fixing scheme for seismic brackets;

Installation steps

Drilling: Select the appropriate drill bit based on the diameter of the anchor bolt, mark the installation position on the concrete ceiling, and then proceed with drilling.

Cleaning the borehole: After drilling, use a compressed air gun or specialized borehole cleaning tool to thoroughly clean the dust and debris inside the borehole.

Installation of anchor bolts: Place the ceiling anchor bolts into the borehole. For anchor bolts with expansion sleeves, ensure that the expansion sleeve is installed correctly and tightly with the anchor bolt body. Then, install the object that needs to be fixed through the threaded end of the anchor bolt, and fit it with a washer and nut. For heavier objects, larger sized washers and nuts may be required to increase the load-bearing area and distribute the pressure of the object on the anchor bolt.

Tighten anchor bolt: Use a wrench or power tool to tighten the nut to the specified torque value. Different specifications of anchor bolts have corresponding recommended torque values. During the tightening process, attention should be paid to uniform force to avoid damage to the anchor bolts or cracking of the concrete due to excessive torque. If the torque is too small, the anchor bolts will not be firmly fixed.

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>