Clevis Pin With Hole

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Clevis Pin

Wire Lock Clevis Pin Title:

Stainless Steel & Steel Clevis Pin with R pin for Fastening

Standard & Adjustable Clevis Pin Introduction:

Clevis Pin is the most common type of U-shaped pin, which is used to secure parts with an open pin R-type snap spring. Simply slide the open pin into the hole. These pins have a flat, low profile head that can be installed in narrow spaces. The core function is to provide a rigid connection that resists shear forces, while allowing the connected component to freely swing within a certain angle.

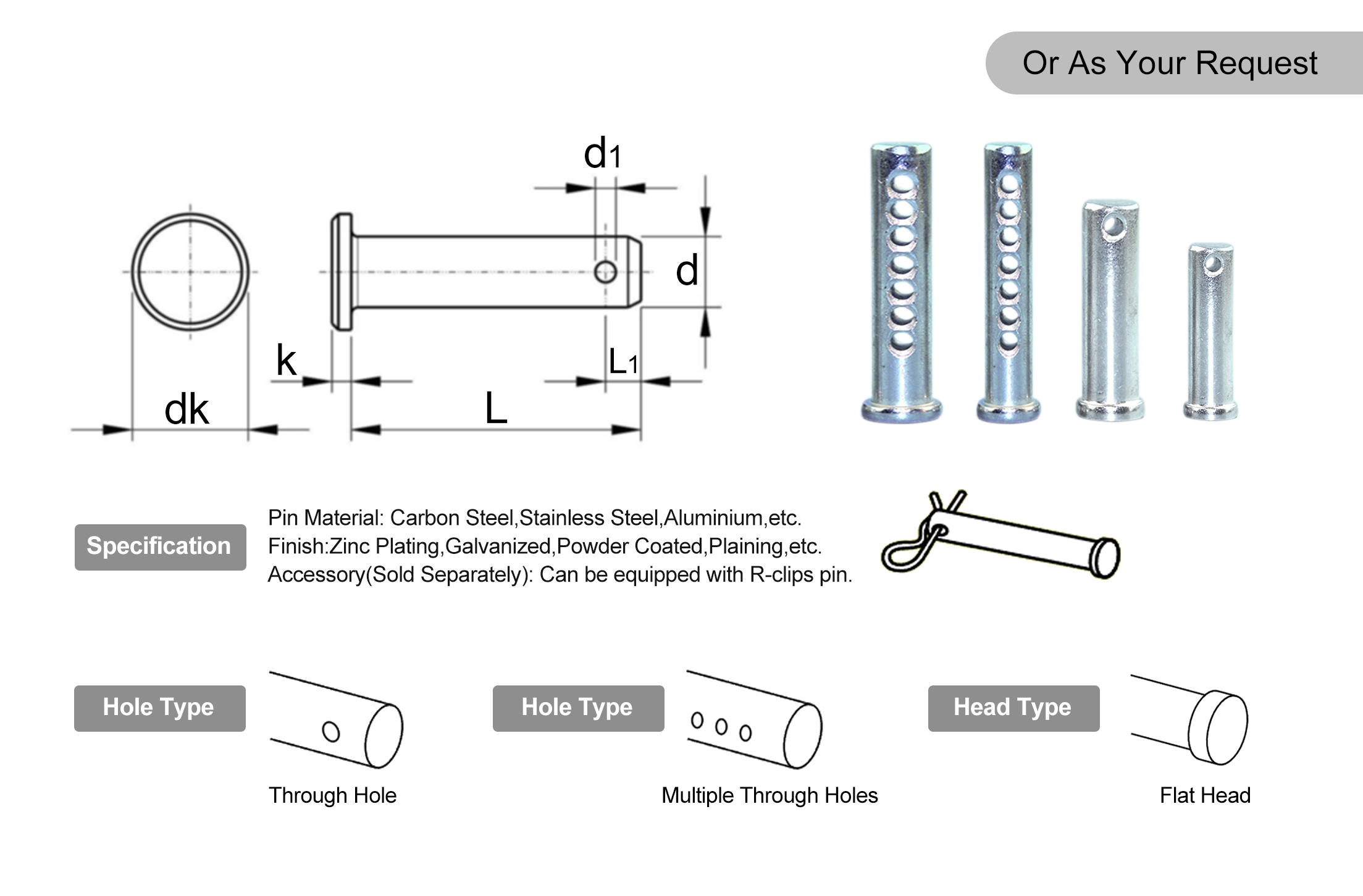

Lock hole design: single or double hole as well as porous structure, suitable for installation with cotter pins/R-type snap springs;

Material and Craftsmanship:

18-8 stainless steel: namely 304 stainless steel, with balanced corrosion resistance and strength, and strong universality;

Carbon steel (galvanized): surface galvanized for rust prevention, low cost, widely used in conventional scenarios such as agricultural machinery and trailers;

Notes:

Headed is a standard design that can prevent the pin from falling off; Surface treatment includes zinc plated, plain, etc

Modle Number:

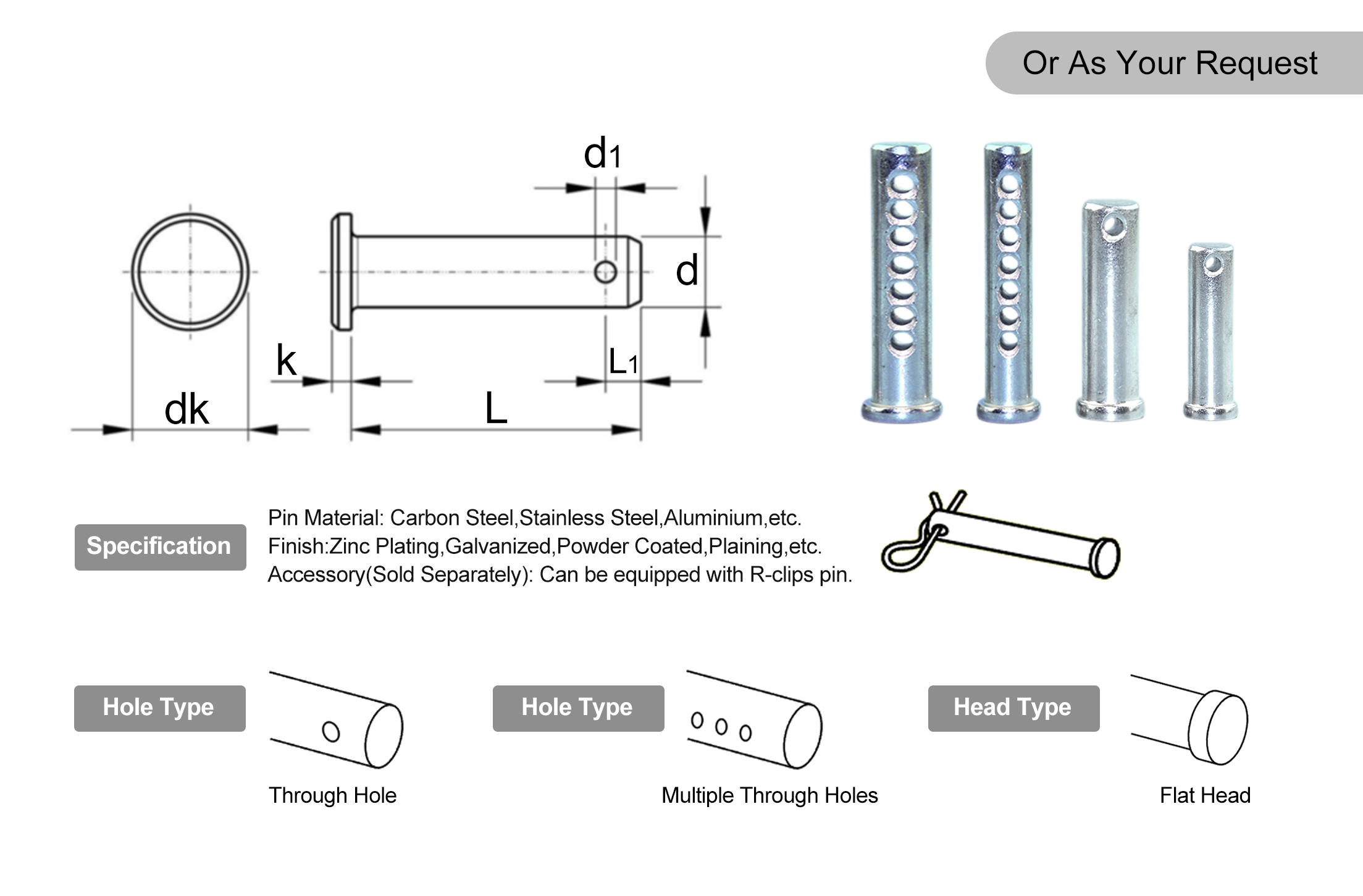

Pin Dia.:3mm,4mm,6mm,8mm,12mm or Customized

Hole Dia.0.8mm,1.2mm,1.6mm,2mm,3.2mm,4.0mm or Customized

Head Dia.:5mm,6mm,8mm,10mm,14mm(See specification sheet for details)

| d | dk | K | d1 | L1 |

| 3 | 5.0 | 1.0 | 0.8 | 1.6 |

| 4 | 6.0 | 1.0 | 1.0 | 2.2 |

| 5 | 8.0 | 1.6 | 1.2 | 2.9 |

| 6 | 10.0 | 2.0 | 1.6 | 3.2 |

| 8 | 14.0 | 3.0 | 2.0 | 3.5 |

| 10 | 18.0 | 4.0 | 3.2 | 4.5 |

| 12 | 20.0 | 4.0 | 3.2 | 5.5 |

| 14 | 22.0 | 4.0 | 4.0 | 6.0 |

| 16 | 25.0 | 4.5 | 4.0 | 6.0 |

| 18 | 28.0 | 5.0 | 5.0 | 7.0 |

| 20 | 30.0 | 5.0 | 5.0 | 8.0 |

| 22 | 33.0 | 5.5 | 5.0 | 8.0 |

| 24 | 36.0 | 6.0 | 6.3 | 9.0 |

Application:

Rail transit brake lever fork, ship transportation, trailer, agricultural machinery traction connection, etc;

Installation steps:

Clean the U-shaped fork hole and pin shaft;

Align the pin shaft with the U-shaped fork hole and smoothly push it in along the axis direction until the pin head fully fits the end face of the fork arm;

Lock and fix

Cotter Pin:

Pass through the radial hole at the end of the pin and open the two arms of the pin at an angle of ≥ 90 ° (to prevent detachment).

R-Clip:

After inserting the pin tail hole, ensure that the spring arm is engaged in the groove (manually press to lock).

Nut locking:

The threaded pin shaft needs to be matched with an anti loosening nut (such as a nylon lock nut), and the torque should be applied according to the specifications;

Features of Clevis Pin

Wire Lock Clevis Pin Title:

Stainless Steel & Steel Clevis Pin with R pin for Fastening

Standard & Adjustable Clevis Pin Introduction:

Clevis Pin is the most common type of U-shaped pin, which is used to secure parts with an open pin R-type snap spring. Simply slide the open pin into the hole. These pins have a flat, low profile head that can be installed in narrow spaces. The core function is to provide a rigid connection that resists shear forces, while allowing the connected component to freely swing within a certain angle.

Lock hole design: single or double hole as well as porous structure, suitable for installation with cotter pins/R-type snap springs;

Material and Craftsmanship:

18-8 stainless steel: namely 304 stainless steel, with balanced corrosion resistance and strength, and strong universality;

Carbon steel (galvanized): surface galvanized for rust prevention, low cost, widely used in conventional scenarios such as agricultural machinery and trailers;

Notes:

Headed is a standard design that can prevent the pin from falling off; Surface treatment includes zinc plated, plain, etc

Modle Number:

Pin Dia.:3mm,4mm,6mm,8mm,12mm or Customized

Hole Dia.0.8mm,1.2mm,1.6mm,2mm,3.2mm,4.0mm or Customized

Head Dia.:5mm,6mm,8mm,10mm,14mm(See specification sheet for details)

| d | dk | K | d1 | L1 |

| 3 | 5.0 | 1.0 | 0.8 | 1.6 |

| 4 | 6.0 | 1.0 | 1.0 | 2.2 |

| 5 | 8.0 | 1.6 | 1.2 | 2.9 |

| 6 | 10.0 | 2.0 | 1.6 | 3.2 |

| 8 | 14.0 | 3.0 | 2.0 | 3.5 |

| 10 | 18.0 | 4.0 | 3.2 | 4.5 |

| 12 | 20.0 | 4.0 | 3.2 | 5.5 |

| 14 | 22.0 | 4.0 | 4.0 | 6.0 |

| 16 | 25.0 | 4.5 | 4.0 | 6.0 |

| 18 | 28.0 | 5.0 | 5.0 | 7.0 |

| 20 | 30.0 | 5.0 | 5.0 | 8.0 |

| 22 | 33.0 | 5.5 | 5.0 | 8.0 |

| 24 | 36.0 | 6.0 | 6.3 | 9.0 |

Application:

Rail transit brake lever fork, ship transportation, trailer, agricultural machinery traction connection, etc;

Installation steps:

Clean the U-shaped fork hole and pin shaft;

Align the pin shaft with the U-shaped fork hole and smoothly push it in along the axis direction until the pin head fully fits the end face of the fork arm;

Lock and fix

Cotter Pin:

Pass through the radial hole at the end of the pin and open the two arms of the pin at an angle of ≥ 90 ° (to prevent detachment).

R-Clip:

After inserting the pin tail hole, ensure that the spring arm is engaged in the groove (manually press to lock).

Nut locking:

The threaded pin shaft needs to be matched with an anti loosening nut (such as a nylon lock nut), and the torque should be applied according to the specifications;

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>