Copper Sealing Washers

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Flat Copper Sealing Washers

Copper Washer Kit Title:

High Temperature Resistance copper crush washers bunnings copper sealing washers M6 M8 washer for shaft

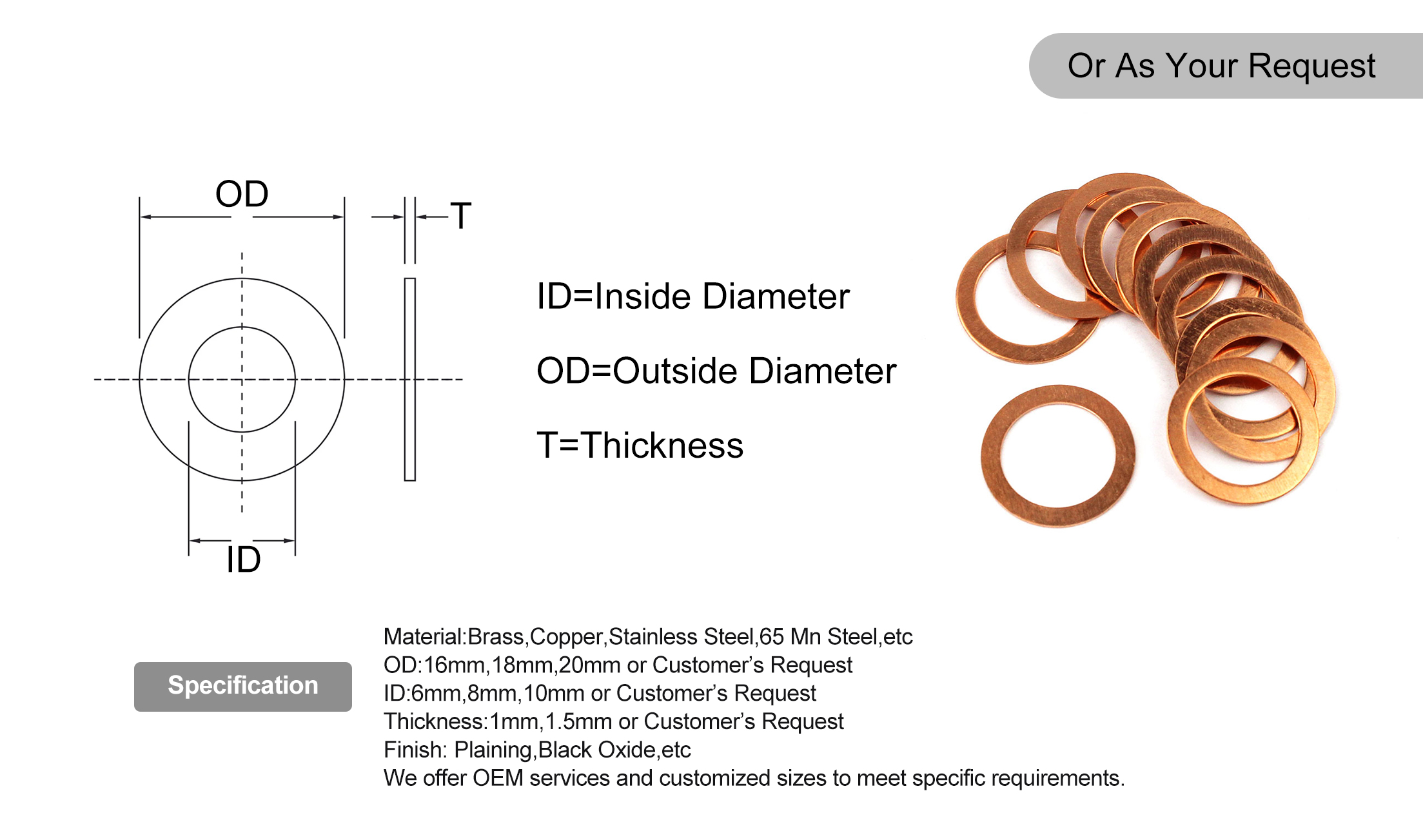

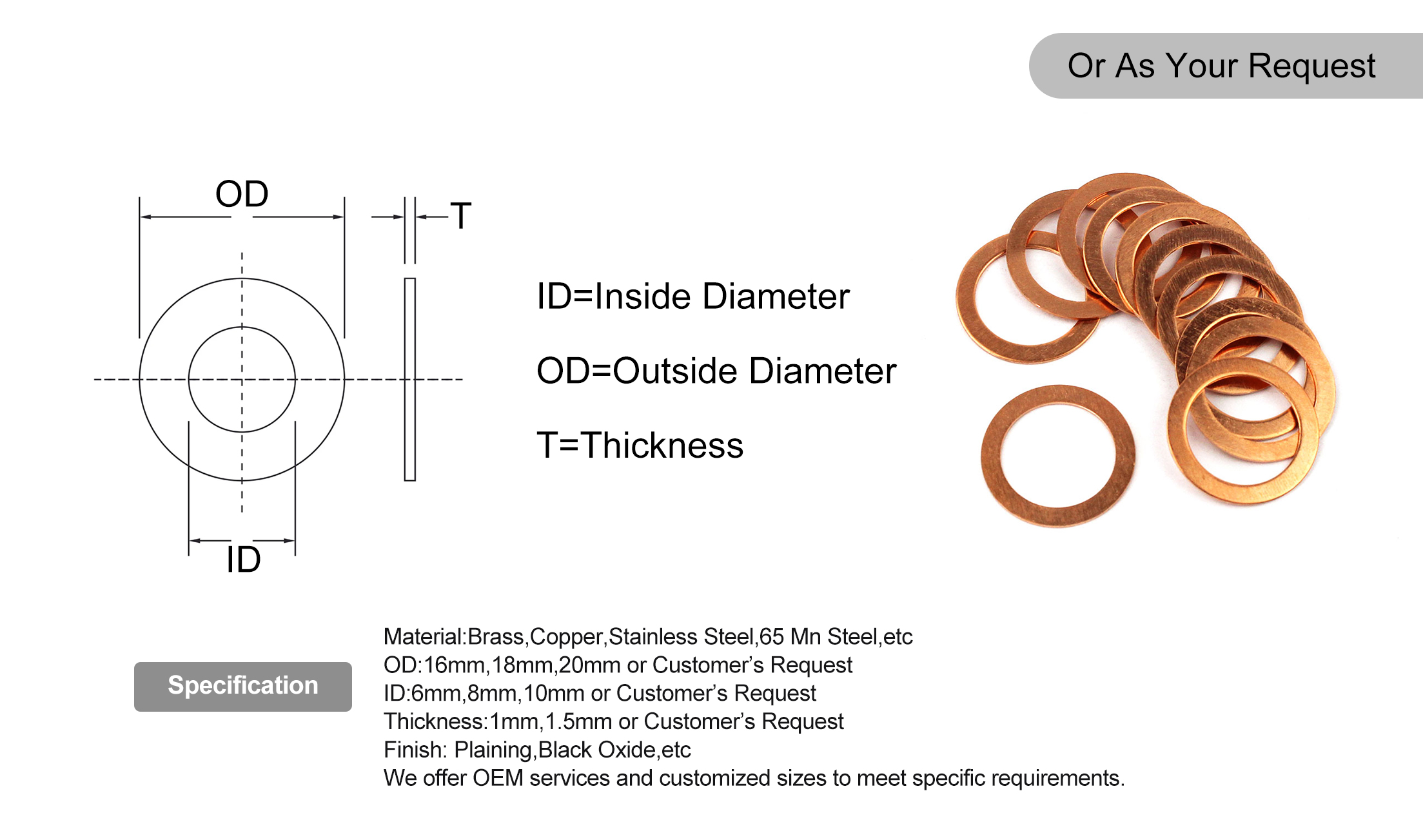

Core structural dimensions:

Inner hole diameter (ID): adapted to the nominal diameter of the bolt/pipe diameter, it needs to be precisely matched with the bolt rod/pipe joint to avoid excessive clearance and seal deviation;

Outer diameter (OD): Based on the size of the sealing surface, the sealing contact area is determined and needs to cover the effective area of the sealing groove/joint surface of the connecting piece;

Thickness (T): The core sealing parameter is usually 0.5-5mm. The thickness is adjusted according to the working pressure and the flatness of the joint surface. The greater the pressure/the rougher the contact surface, the greater the thickness adaptation.

For special sealing scenarios, customized non-standard size/special structure copper sealing flat gaskets can be used:

Non standard dimensions: oversized inner/outer diameter, ultra-thin/ultra-thin (such as 0.2mm ultra-thin, 10mm ultra-thin), asymmetric annular dimensions;

Special structure: with chamfer/groove (for easy assembly into the sealing groove), with positioning protrusion (to prevent sealing deviation), irregular ring (suitable for non-circular sealing surfaces);

Composite structure: Copper and rubber/asbestos composite (improves low-temperature/low-pressure sealing effect, called copper pad).

Core production process: The purple copper sealing flat gasket is mainly produced by cold processing due to the soft pure copper substrate. The core requirements are to ensure flatness, no burrs, and precise size, and avoid affecting the sealing effect.

Production process:

Raw material selection: T2/T3 oxygen free copper strip/copper plate, etc. are selected;

Precise cutting

According to the specifications and dimensions, circular cutting of the copper strip/plate is carried out using a CNC punching machine/laser cutting machine to ensure the tolerance of the inner hole and outer diameter dimensions;

Edge finishing

Process the cutting edges with chamfering and deburring machines to remove burrs and burrs, avoiding scratches on the sealing surface and affecting the fit during installation;

Thickness leveling is achieved by using a leveling machine to fine tune the gasket, ensuring uniform overall thickness;

Surface treatment:

The default color cleaning for copper washers is to remove surface oil stains and oxide layers, while maintaining the original color of the metal; Special requirements can be treated with tin/nickel plating to enhance oxidation resistance;

Packaging inspection: Use anti oxidation packaging (vacuum bag/rust proof paper) to avoid oxidation during transportation and storage.

| Dimensions (mm) | |||

| Size | ID(mm) | OD(mm) | T(mm) |

| M5 | 5mm | 9mm | 1mm |

| M6 | 6mm | 10mm | 1mm |

| M6 | 6mm | 12mm | 1mm |

| M8 | 8mm | 12mm | 1mm |

| M8 | 8mm | 14mm | 1mm |

| M10 | 10mm | 14mm | 1mm |

| M12 | 12mm | 16mm | 1mm |

| M12 | 12mm | 18mm | 1.5mm |

| M14 | 14mm | 20mm | 1mm |

| M16 | 16mm | 22mm | 1mm |

| M20 | 20mm | 26mm | 1.5mm |

Crush Sealing Copper Washer Applications:

Hydraulic and pneumatic equipment: flat seals for hydraulic stations, oil cylinders, air cylinders, solenoid valves, and pipe joints, capable of withstanding hydraulic oil and compressed air media;

Water heating and gas pipelines: flange/joint seals for tap water pipelines, gas pipelines, radiators, and water heaters. Food grade copper pads can be used for drinking water pipelines;

Power machinery: oil/air duct seals for internal combustion engines, generators, and air compressors, adapted to the medium temperature conditions of the equipment;

Food/pharmaceutical equipment:Sanitary grade sealing of food and beverage production lines, pharmaceutical dispensing pipelines, free from medium contamination, in compliance with industry hygiene standards;

General machinery: machine tools, reducers, and air compressors have joint surfaces and flange seals, while dispersing fastening pressure to protect equipment contact surfaces.

Core features:

Excellent plastic deformation ability and good temperature resistance

High thermal conductivity+electrical conductivity: Copper has excellent thermal and electrical conductivity, and can achieve dual functions of sealing, thermal conductivity, and grounding, suitable for sealing scenarios with thermal and electrical conductivity requirements;

Easy to install and replace: The structure is a flat ring shape with no installation direction requirements. After disassembly, it can be determined whether to reuse based on deformation.

Features of Flat Copper Sealing Washers

Copper Washer Kit Title:

High Temperature Resistance copper crush washers bunnings copper sealing washers M6 M8 washer for shaft

Core structural dimensions:

Inner hole diameter (ID): adapted to the nominal diameter of the bolt/pipe diameter, it needs to be precisely matched with the bolt rod/pipe joint to avoid excessive clearance and seal deviation;

Outer diameter (OD): Based on the size of the sealing surface, the sealing contact area is determined and needs to cover the effective area of the sealing groove/joint surface of the connecting piece;

Thickness (T): The core sealing parameter is usually 0.5-5mm. The thickness is adjusted according to the working pressure and the flatness of the joint surface. The greater the pressure/the rougher the contact surface, the greater the thickness adaptation.

For special sealing scenarios, customized non-standard size/special structure copper sealing flat gaskets can be used:

Non standard dimensions: oversized inner/outer diameter, ultra-thin/ultra-thin (such as 0.2mm ultra-thin, 10mm ultra-thin), asymmetric annular dimensions;

Special structure: with chamfer/groove (for easy assembly into the sealing groove), with positioning protrusion (to prevent sealing deviation), irregular ring (suitable for non-circular sealing surfaces);

Composite structure: Copper and rubber/asbestos composite (improves low-temperature/low-pressure sealing effect, called copper pad).

Core production process: The purple copper sealing flat gasket is mainly produced by cold processing due to the soft pure copper substrate. The core requirements are to ensure flatness, no burrs, and precise size, and avoid affecting the sealing effect.

Production process:

Raw material selection: T2/T3 oxygen free copper strip/copper plate, etc. are selected;

Precise cutting

According to the specifications and dimensions, circular cutting of the copper strip/plate is carried out using a CNC punching machine/laser cutting machine to ensure the tolerance of the inner hole and outer diameter dimensions;

Edge finishing

Process the cutting edges with chamfering and deburring machines to remove burrs and burrs, avoiding scratches on the sealing surface and affecting the fit during installation;

Thickness leveling is achieved by using a leveling machine to fine tune the gasket, ensuring uniform overall thickness;

Surface treatment:

The default color cleaning for copper washers is to remove surface oil stains and oxide layers, while maintaining the original color of the metal; Special requirements can be treated with tin/nickel plating to enhance oxidation resistance;

Packaging inspection: Use anti oxidation packaging (vacuum bag/rust proof paper) to avoid oxidation during transportation and storage.

| Dimensions (mm) | |||

| Size | ID(mm) | OD(mm) | T(mm) |

| M5 | 5mm | 9mm | 1mm |

| M6 | 6mm | 10mm | 1mm |

| M6 | 6mm | 12mm | 1mm |

| M8 | 8mm | 12mm | 1mm |

| M8 | 8mm | 14mm | 1mm |

| M10 | 10mm | 14mm | 1mm |

| M12 | 12mm | 16mm | 1mm |

| M12 | 12mm | 18mm | 1.5mm |

| M14 | 14mm | 20mm | 1mm |

| M16 | 16mm | 22mm | 1mm |

| M20 | 20mm | 26mm | 1.5mm |

Crush Sealing Copper Washer Applications:

Hydraulic and pneumatic equipment: flat seals for hydraulic stations, oil cylinders, air cylinders, solenoid valves, and pipe joints, capable of withstanding hydraulic oil and compressed air media;

Water heating and gas pipelines: flange/joint seals for tap water pipelines, gas pipelines, radiators, and water heaters. Food grade copper pads can be used for drinking water pipelines;

Power machinery: oil/air duct seals for internal combustion engines, generators, and air compressors, adapted to the medium temperature conditions of the equipment;

Food/pharmaceutical equipment:Sanitary grade sealing of food and beverage production lines, pharmaceutical dispensing pipelines, free from medium contamination, in compliance with industry hygiene standards;

General machinery: machine tools, reducers, and air compressors have joint surfaces and flange seals, while dispersing fastening pressure to protect equipment contact surfaces.

Core features:

Excellent plastic deformation ability and good temperature resistance

High thermal conductivity+electrical conductivity: Copper has excellent thermal and electrical conductivity, and can achieve dual functions of sealing, thermal conductivity, and grounding, suitable for sealing scenarios with thermal and electrical conductivity requirements;

Easy to install and replace: The structure is a flat ring shape with no installation direction requirements. After disassembly, it can be determined whether to reuse based on deformation.

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>