Custom Metal Fabrication Parts

PDM

| Availability: | |

|---|---|

| Quantity: | |

Custom Metal Fabrication Service

Custom sheet metal fabrication Title:

Sheet metal fabrication manufacturer & sheet metal fabrication metal parts formal

The main features of sheet metal fabrication parts include light weight, high strength, excellent conductivity (suitable for electromagnetic shielding), low cost, and good mass production ability. This process is widely used in fields such as electronic appliances, automotive industry, medical equipment, and building structures, such as computer cases, vehicle body components, and home appliance casings. Unlike modern injection molding processes, sheet metal parts often require multiple process combinations to complete, which increases production complexity but enhances design flexibility;

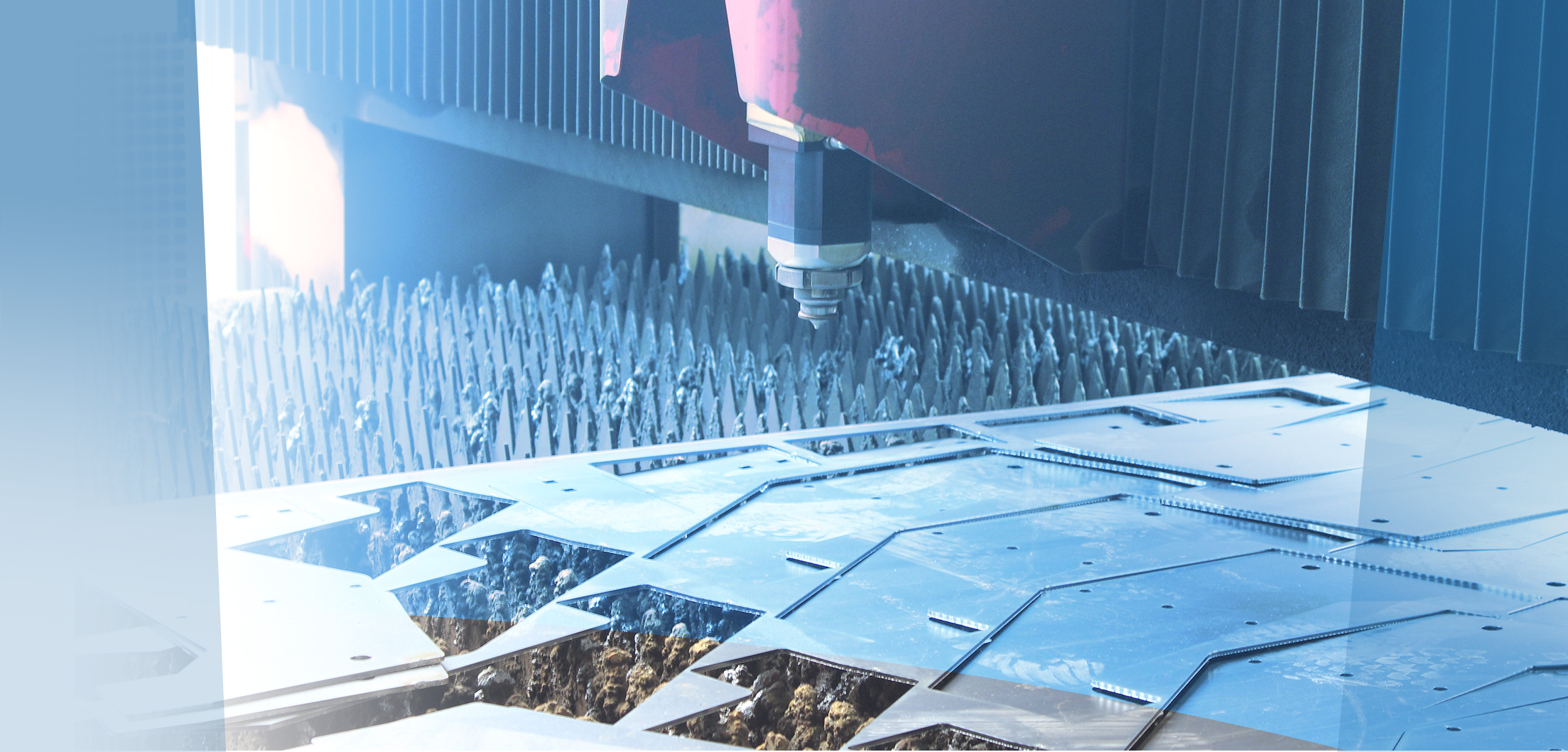

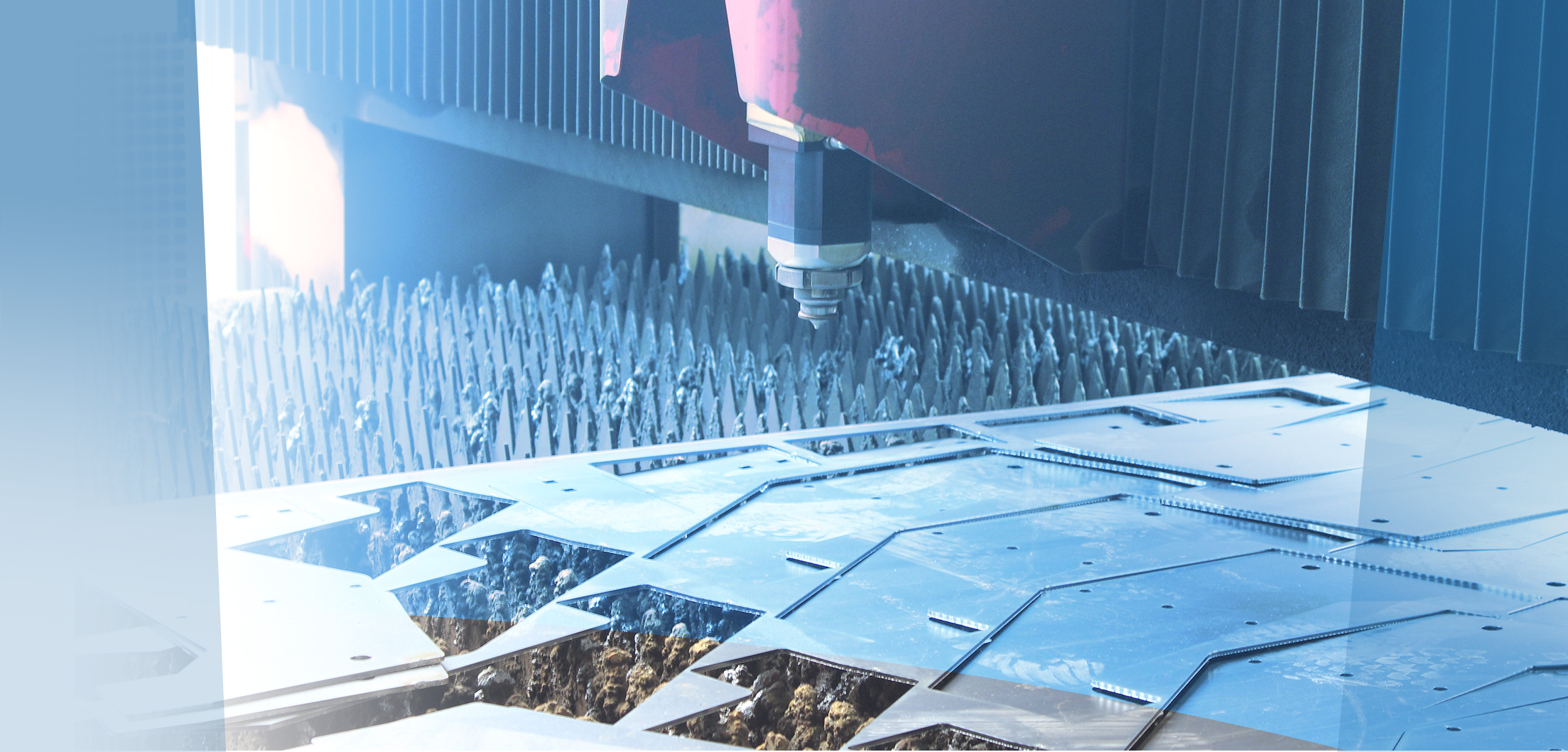

Key Process Steps: Cutting

Common methods for cutting metal sheets into the desired shape according to design include:

Laser Cutting: High precision processing of complex contours, suitable for stainless steel, aluminum, and other materials.

Plasma Cutting: Suitable for thicker plates, with high efficiency but slightly lower accuracy.

Other techniques such as Water Jet Cutting are used to avoid thermal deformation.

Forming:

Bending: The sheet metal is bent into an angle using a CNC press brake, and the ratio of bending radius to thickness is a key parameter.

Deep Drawing: To stretch the sheet into a deep cavity shape (such as a container) in the mold, it is necessary to control the fluidity of the material.

Curling and Spinning: Used to create cylindrical or axisymmetric components.

Joining and Assembly:

Welding: including fusion welding and brazing, connecting components and ensuring structural strength.

Hemming: Processing edges to enhance durability (such as car door panels).

Surface treatment:

In order to improve the corrosion resistance, wear resistance, and aesthetics of sheet metal parts, surface treatment such as spraying, electroplating, anodizing, etc. is usually required. Spraying is the most common surface treatment method, and different coating colors and types can be selected according to needs.

Anodizing: enhances the hardness and aesthetics of aluminum materials.

Powder Coating: Provides a uniform protective layer, suitable for outdoor equipment.

Application Area

Industrial equipment:such as automated production line equipment, machine tool protective covers, ventilation duct systems, etc., require customized design of sheet metal parts based on specific production processes and spatial layouts to meet the functional and installation requirements of the equipment.

Communication industry: Communication cabinets, server cases, etc. require good electromagnetic shielding performance, heat dissipation performance, and structural strength to protect the normal operation of internal electronic equipment.

Medical equipment:such as medical instrument casings, surgical table accessories, etc., have high requirements for the accuracy, hygiene, and safety of sheet metal parts. Customized sheet metal parts can meet the special design and usage needs of medical equipment.

Transportation: The interior, exterior, and structural components of vehicles such as cars, trains, and airplanes, such as car luggage racks and train carriage connecting plates, need to be customized and produced according to the overall design and performance requirements of the vehicles.

Notes:

Metal Brackets Fabrication Parts Display:

Custom Metal Fabrication Service

Custom sheet metal fabrication Title:

Sheet metal fabrication manufacturer & sheet metal fabrication metal parts formal

The main features of sheet metal fabrication parts include light weight, high strength, excellent conductivity (suitable for electromagnetic shielding), low cost, and good mass production ability. This process is widely used in fields such as electronic appliances, automotive industry, medical equipment, and building structures, such as computer cases, vehicle body components, and home appliance casings. Unlike modern injection molding processes, sheet metal parts often require multiple process combinations to complete, which increases production complexity but enhances design flexibility;

Key Process Steps: Cutting

Common methods for cutting metal sheets into the desired shape according to design include:

Laser Cutting: High precision processing of complex contours, suitable for stainless steel, aluminum, and other materials.

Plasma Cutting: Suitable for thicker plates, with high efficiency but slightly lower accuracy.

Other techniques such as Water Jet Cutting are used to avoid thermal deformation.

Forming:

Bending: The sheet metal is bent into an angle using a CNC press brake, and the ratio of bending radius to thickness is a key parameter.

Deep Drawing: To stretch the sheet into a deep cavity shape (such as a container) in the mold, it is necessary to control the fluidity of the material.

Curling and Spinning: Used to create cylindrical or axisymmetric components.

Joining and Assembly:

Welding: including fusion welding and brazing, connecting components and ensuring structural strength.

Hemming: Processing edges to enhance durability (such as car door panels).

Surface treatment:

In order to improve the corrosion resistance, wear resistance, and aesthetics of sheet metal parts, surface treatment such as spraying, electroplating, anodizing, etc. is usually required. Spraying is the most common surface treatment method, and different coating colors and types can be selected according to needs.

Anodizing: enhances the hardness and aesthetics of aluminum materials.

Powder Coating: Provides a uniform protective layer, suitable for outdoor equipment.

Application Area

Industrial equipment:such as automated production line equipment, machine tool protective covers, ventilation duct systems, etc., require customized design of sheet metal parts based on specific production processes and spatial layouts to meet the functional and installation requirements of the equipment.

Communication industry: Communication cabinets, server cases, etc. require good electromagnetic shielding performance, heat dissipation performance, and structural strength to protect the normal operation of internal electronic equipment.

Medical equipment:such as medical instrument casings, surgical table accessories, etc., have high requirements for the accuracy, hygiene, and safety of sheet metal parts. Customized sheet metal parts can meet the special design and usage needs of medical equipment.

Transportation: The interior, exterior, and structural components of vehicles such as cars, trains, and airplanes, such as car luggage racks and train carriage connecting plates, need to be customized and produced according to the overall design and performance requirements of the vehicles.

Notes:

Metal Brackets Fabrication Parts Display:

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>