Custom Plastic Parts

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Inject Plastic Mold

Plastic Injection Manufacturing Title:

Professional Manufacturer plastic & rubber machinery parts extruded plastic parts

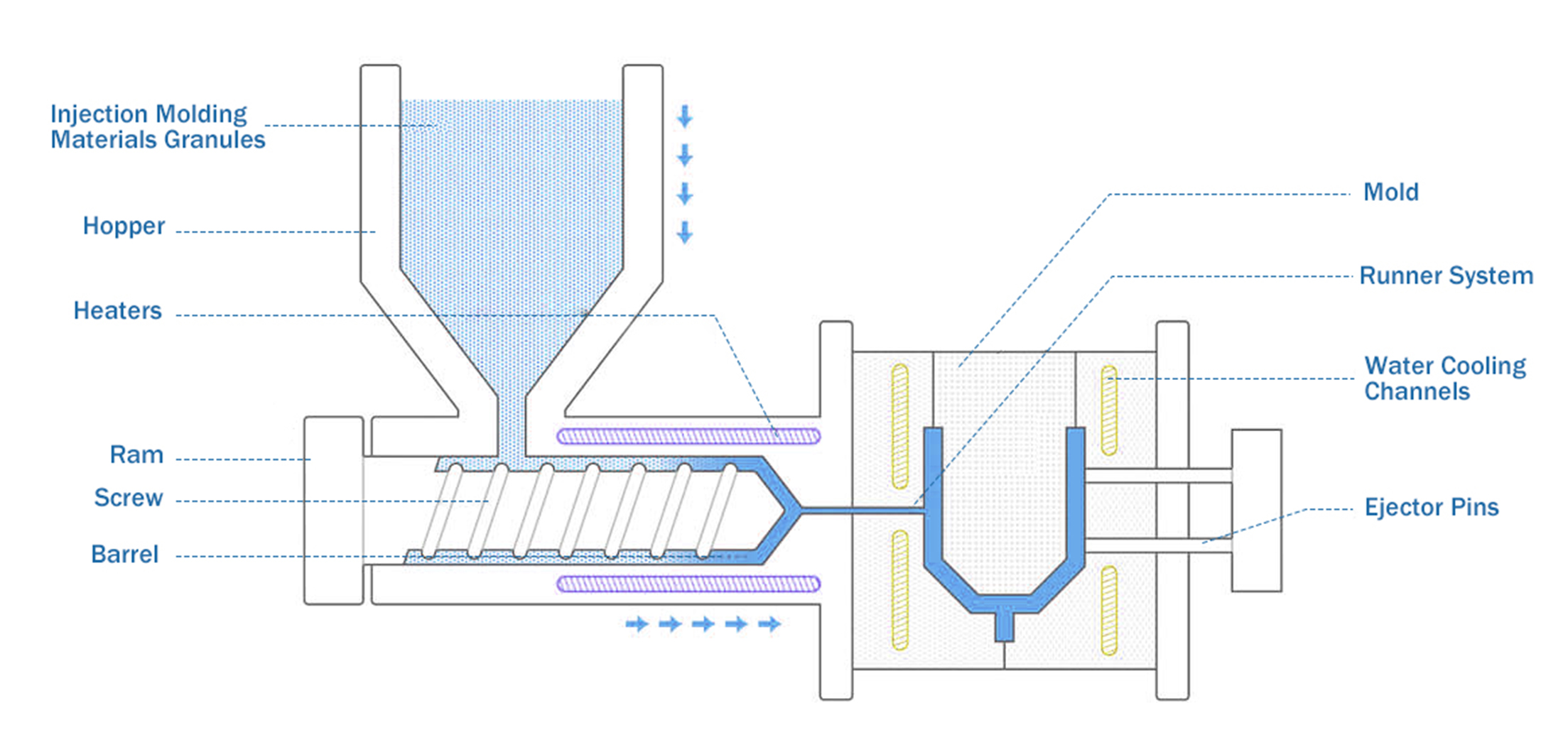

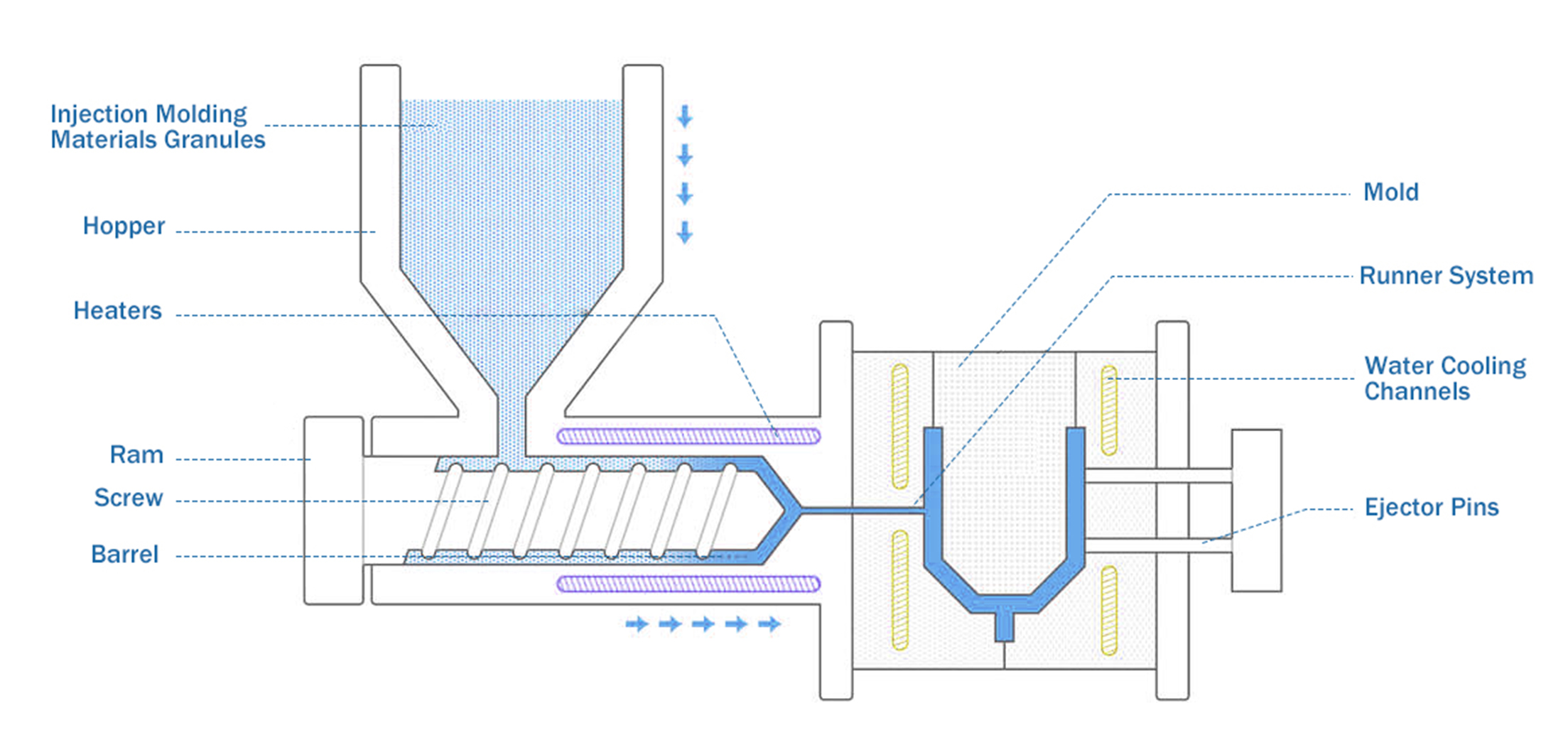

Injection molding is a method of industrial product production molding, mainly used for manufacturing plastic or rubber products. Its core is to inject molten raw materials into the mold cavity for cooling and solidification molding. Injection molded parts are characterized by standardized geometric shapes and high surface smoothness, meeting the precision requirements of industrial assembly.

The injection molding process relies on precision molds and injection molding machine equipment. Plastic particles (such as ABS, PP, etc.) heated to melt are injected into a closed mold through high pressure, and after pressure holding and cooling, they are demolded to obtain the finished product.

Melting stage: Plastic particles are heated in the hopper to a molten state.

Injection stage: The melt is injected into the closed mold at high speed under high pressure.

Cooling solidification: After the plastic inside the mold cools and solidifies, it is demolded to form the final part.

The process relies on precision molds (such as thermoplastic injection molds) and parameter control (such as pressure and temperature) to ensure dimensional stability

Whether you need the optical purity of medical grade transparent parts or the integrated molding of multi-color textures for automotive interiors, our intelligent injection molding system can achieve millimeter level precision control. By combining modular processes (from gas assisted to micro foaming), while ensuring mechanical indicators such as impact resistance and weather resistance;

Core advantages:

Repeatability: Metal molds ensure high consistency of parts during mass production, making them suitable for large-scale manufacturing.

Cost effectiveness: The initial mold cost is relatively high, but the single piece cost is significantly reduced during mass production.

Material adaptability: compatible with various plastics (such as ABS, polypropylene, nylon), supporting rigid or flexible component requirements.

Main application areas:

Widely used in the automotive industry (such as door substrates, seat components), electronic components (such as circuit board housings), consumer product packaging, and industrial assembly parts, emphasizing lightweight and high reliability.

Plastic Injection Parts Inspection

Dimensional inspection

Dimensional inspection is the technical core of quality control for injection molded parts, requiring professional measuring equipment (such as coordinate measuring machines, projectors, calipers, etc.) and strong technical analysis skills.

In contrast, visual inspection focuses on the intuitive evaluation of product surface features:

Color and Gloss: Verify whether the product color and surface glossiness are completely consistent with the standard sample (main sample) to ensure visual consistency;

Surface defect identification: including the detection of common injection molding defects such as shrinkage marks, flash marks, weld marks, bubbles, scorch marks, and silver lines;

Surface smoothness evaluation: Check whether the surface roughness meets the design requirements;

Integrity of identification: Confirm the clarity and positional accuracy of printed or engraved content such as nameplates, text, patterns, etc;

Notes:

Plastic part machining parts pom plastic display:

Features of Inject Plastic Mold

Plastic Injection Manufacturing Title:

Professional Manufacturer plastic & rubber machinery parts extruded plastic parts

Injection molding is a method of industrial product production molding, mainly used for manufacturing plastic or rubber products. Its core is to inject molten raw materials into the mold cavity for cooling and solidification molding. Injection molded parts are characterized by standardized geometric shapes and high surface smoothness, meeting the precision requirements of industrial assembly.

The injection molding process relies on precision molds and injection molding machine equipment. Plastic particles (such as ABS, PP, etc.) heated to melt are injected into a closed mold through high pressure, and after pressure holding and cooling, they are demolded to obtain the finished product.

Melting stage: Plastic particles are heated in the hopper to a molten state.

Injection stage: The melt is injected into the closed mold at high speed under high pressure.

Cooling solidification: After the plastic inside the mold cools and solidifies, it is demolded to form the final part.

The process relies on precision molds (such as thermoplastic injection molds) and parameter control (such as pressure and temperature) to ensure dimensional stability

Whether you need the optical purity of medical grade transparent parts or the integrated molding of multi-color textures for automotive interiors, our intelligent injection molding system can achieve millimeter level precision control. By combining modular processes (from gas assisted to micro foaming), while ensuring mechanical indicators such as impact resistance and weather resistance;

Core advantages:

Repeatability: Metal molds ensure high consistency of parts during mass production, making them suitable for large-scale manufacturing.

Cost effectiveness: The initial mold cost is relatively high, but the single piece cost is significantly reduced during mass production.

Material adaptability: compatible with various plastics (such as ABS, polypropylene, nylon), supporting rigid or flexible component requirements.

Main application areas:

Widely used in the automotive industry (such as door substrates, seat components), electronic components (such as circuit board housings), consumer product packaging, and industrial assembly parts, emphasizing lightweight and high reliability.

Plastic Injection Parts Inspection

Dimensional inspection

Dimensional inspection is the technical core of quality control for injection molded parts, requiring professional measuring equipment (such as coordinate measuring machines, projectors, calipers, etc.) and strong technical analysis skills.

In contrast, visual inspection focuses on the intuitive evaluation of product surface features:

Color and Gloss: Verify whether the product color and surface glossiness are completely consistent with the standard sample (main sample) to ensure visual consistency;

Surface defect identification: including the detection of common injection molding defects such as shrinkage marks, flash marks, weld marks, bubbles, scorch marks, and silver lines;

Surface smoothness evaluation: Check whether the surface roughness meets the design requirements;

Integrity of identification: Confirm the clarity and positional accuracy of printed or engraved content such as nameplates, text, patterns, etc;

Notes:

Plastic part machining parts pom plastic display:

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>