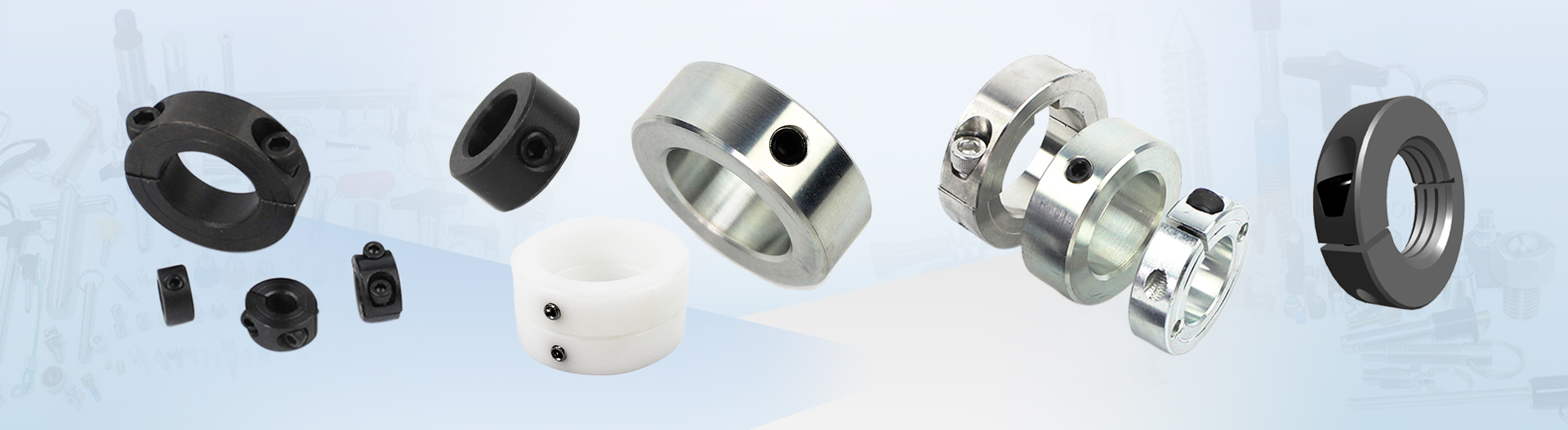

Double Split Shaft Collars

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Double Split Shaft Collar

Two Pieces Split Shaft Collar Title:

steel & aluminum double split shaft collars custom shaft collar with keyway for positioning bearings

The locking clamp collar achieves ± 0.01mm radial runout control through a dual split structure, synchronously solving the axial displacement problem of traditional clamping collars;

Advantages of clamping shaft collars:

The Heavy Duty Double Split Shaft Collar is made of forged 420 stainless steel, 304 stainless steel, and nickel plated carbon steel, with a variety of material options, and a tensile strength of up to 1200MPa. Double split design combined with 12.9 level hex screws, providing a large aperture range of 25mm-150mm, with optional phosphating or Dacromet treatment on the surface to meet extreme environmental requirements.

The Sanitary Double Split Shaft Collar can be fully mirror polished, and the double split ring body is made of 316L stainless steel integrated molding. The sealing groove design of the clamping collar is specially optimized, suitable for GMP scenarios such as pharmaceutical filling equipment and dairy pumps;

| Inch-Set Screw Shaft Collar |

|

| Bore | O.D. | Width | Cap Screw |

| 1/8" | 5/8" | 5/16" | 4-40 x 3/8 |

| 3/16" | 5/8" | 5/16" | 4-40 x 3/8 |

| 1/4" | 11/16" | 5/16" | 4-40 x 3/8 |

| 5/16" | 11/16" | 5/16" | 4-40 x 3/8 |

| 3/8" | 7/8" | 3/8" | 6-32 x 3/8 |

| 7/16" | 15/16" | 3/8" | 6-32 x 3/8 |

| 1/2" | 1 1/8" | 13/32" | 8-32 x 1/2 |

| 9/16" | 1 5/16" | 7/16" | 10-32 x 1/2 |

| 5/8" | 1 5/16" | 7/16" | 10-32 x 1/2 |

| 11/16" | 1 1/2" | 1/2" | 10-32 x 1/2 |

| 3/4" | 1 1/2" | 1/2" | 1/4-28 x 5/8 |

| 13/16" | 1 5/8" | 1/2" | 1/4-28 x 5/8 |

| 7/8" | 1 5/8" | 1/2" | 1/4-28 x 5/8 |

| 15/16" | 1 3/4" | 1/2" | 1/4-28 x 5/8 |

| 1" | 1 3/4" | 1/2" | 1/4-28 x 5/8 |

| 1 1/16" | 1 7/8" | 1/2" | 1/4-28 x 5/8 |

| 1 1/8" | 1 7/8" | 1/2" | 1/4-28 x 5/8 |

| 1 3/16" | 2 1/16" | 1/2" | 1/4-28 x 3/4 |

| 1 1/4" | 2 1/16" | 1/2" | 1/4-28 x 3/4 |

| 1 5/16" | 2 1/4" | 9/16" | 1/4-28 x 3/4 |

| 1 3/8" | 2 1/4" | 9/16" | 1/4-28 x 3/4 |

| 1 7/16" | 2 1/4" | 9/16" | 1/4-28 x 3/4 |

| 1 1/2" | 2 3/8" | 9/16" | 1/4-28 x 3/4 |

| 1 9/16" | 2 3/8" | 9/16" | 1/4-28 x 3/4 |

| 1 5/8" | 2 5/8" | 11/16" | 5/16-24 x 1 |

| 1 11/16" | 2 3/4" | 11/16" | 5/16-24 x 1 |

| 1 3/4" | 2 3/4" | 11/16" | 5/16-24 x 1 |

| 1 13/16" | 2 7/8" | 11/16" | 5/16-24 x 1 |

| 1 7/8" | 2 7/8" | 11/16" | 5/16-24 x 1 |

| 1 15/16" | 3" | 11/16" | 5/16-24 x 1 |

| 2" | 3" | 11/16" | 5/16-24 x 1 |

| 2 1/16" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 1/8" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 3/16" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 1/4" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 5/16" | 3 1/2" | 3/4" | 5/16-24 x 1 |

| 2 3/8" | 3 1/2" | 3/4" | 5/16-24 x 1 |

| 2 7/16" | 3 1/2" | 3/4" | 5/16-24 x 1 |

| 2 1/2" | 3 3/4" | 7/8" | 3/8-24 x 1 |

| 2 9/16" | 3 7/8" | 7/8" | 3/8-24 x 1 |

| 2 5/8" | 3 7/8" | 7/8" | 3/8-24 x 1 |

| 2 11/16" | 4" | 7/8" | 3/8-24 x 1 |

| 2 3/4" | 4" | 7/8" | 3/8-24 x 1 |

| 2 7/8" | 4 1/4" | 7/8" | 3/8-24 x 1 |

| 2 15/16" | 4 1/4" | 7/8" | 3/8-24 x 1 |

| 3" | 4 1/4" | 7/8" | 3/8-24 x 1 |

| 3 3/16" | 4 1/2" | 7/8" | 3/8-24 x 1 |

| 3 1/4" | 4 1/2" | 7/8" | 3/8-24 x 1 |

| 3 7/16" | 4 3/4" | 7/8" | 3/8-24 x 1 |

| 3 1/2" | 4 3/4" | 7/8" | 3/8-24 x 1 |

| 3 3/4" | 5" | 7/8" | 3/8-24 x 1 |

| 3 15/16" | 5 1/4" | 7/8" | 3/8-24 x 1 |

| 4" | 5 1/4" | 7/8" | 3/8-24 x 1 |

| 4 1/4" | 5 1/2" | 7/8" | 3/8-24 x 1 |

| 4 7/16" | 5 3/4" | 7/8" | 3/8-24 x 1 |

| 4 1/2" | 5 3/4" | 7/8" | 3/8-24 x 1 |

| 4 15/16" | 6 1/4" | 7/8" | 3/8-24 x 1 |

| 5" | 6 1/4" | 7/8" | 3/8-24 x 1 |

| 5 3/16" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 1/4" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 7/16" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 1/2" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 15/16" | 7 1/4" | 7/8" | 3/8-24 x 1 |

| 6" | 7 1/4" | 7/8" | 3/8-24 x 1 |

| Metric-Single Split Shaft Collar |

|

| Bore | O.D. | Width | Set Screw |

| 3mm | 16mm | 9mm | M3 x 8 |

| 4mm | 16mm | 9mm | M3 x 8 |

| 5mm | 16mm | 9mm | M3 x 8 |

| 6mm | 16mm | 9mm | M3 x 8 |

| 7mm | 18mm | 9mm | M3 x 8 |

| 8mm | 18mm | 9mm | M3 x 10 |

| 9mm | 24mm | 9mm | M3 x 10 |

| 10mm | 24mm | 9mm | M3 x 10 |

| 11mm | 28mm | 11mm | M4 x 12 |

| 12mm | 28mm | 11mm | M4 x 12 |

| 13mm | 30mm | 11mm | M4 x 12 |

| 14mm | 30mm | 11mm | M4 x 12 |

| 15mm | 34mm | 13mm | M5 x 16 |

| 16mm | 34mm | 13mm | M5 x 16 |

| 17mm | 36mm | 13mm | M5 x 16 |

| 18mm | 36mm | 13mm | M5 x 16 |

| 19mm | 40mm | 15mm | M6 x 16 |

| 20mm | 40mm | 15mm | M6 x 16 |

| 21mm | 42mm | 15mm | M6 x 16 |

| 22mm | 42mm | 15mm | M6 x 16 |

| 23mm | 45mm | 15mm | M6 x 16 |

| 24mm | 45mm | 15mm | M6 x 16 |

| 25mm | 45mm | 15mm | M6 x 16 |

| 26mm | 48mm | 15mm | M6 x 16 |

| 27mm | 48mm | 15mm | M6 x 16 |

| 28mm | 48mm | 15mm | M6 x 16 |

| 30mm | 54mm | 15mm | M6 x 16 |

| 32mm | 54mm | 15mm | M6 x 16 |

| 34mm | 57mm | 15mm | M6 x 16 |

| 35mm | 57mm | 15mm | M6 x 16 |

| 36mm | 57mm | 15mm | M6 x 16 |

| 38mm | 60mm | 15mm | M6 x 16 |

| 40mm | 60mm | 15mm | M6 x 16 |

| 42mm | 73mm | 19mm | M8 x 25 |

| 45mm | 73mm | 19mm | M8 x 25 |

| 48mm | 78mm | 19mm | M8 x 25 |

| 50mm | 78mm | 19mm | M8 x 25 |

| 54mm | 82mm | 19mm | M8 x 25 |

| 55mm | 82mm | 19mm | M8 x 25 |

| 60mm | 88mm | 19mm | M8 x 25 |

| 65mm | 93mm | 19mm | M8 x 25 |

| 70mm | 98mm | 19mm | M8 x 25 |

| 75mm | 103mm | 19mm | M8 x 25 |

| 80mm | 108mm | 19mm | M8 x 25 |

Applicable Areas:

Industrial transmission system: used to locate transmission components such as bearings and gears to prevent axial displacement;

Applicable equipment: power transmission shaft systems for conveyors/packaging machinery/textile equipment;

Heavy equipment manufacturing: fixing hydraulic system components in mining/agricultural machinery;

Transportation equipment: fixing the motor shaft end of electric vehicles, positioning the transmission system of motorcycles;

Precision Shaft Collar Customization Workflow:

Requirement confirmation stage:

(inner diameter range: 5-200mm/material: carbon steel/stainless steel/aluminum alloy)

3D drawing docking (supports STEP/IGES format)

CNC machining scheme design (± 0.01mm tolerance control)

Prototype sample production (delivered according to the agreed delivery date)

Surface treatment selection (galvanizing/blackening/passivation treatment)

Batch production (supporting 500-50000 orders) delivery service: customized packaging solutions, logistics tracking and other after-sales services;

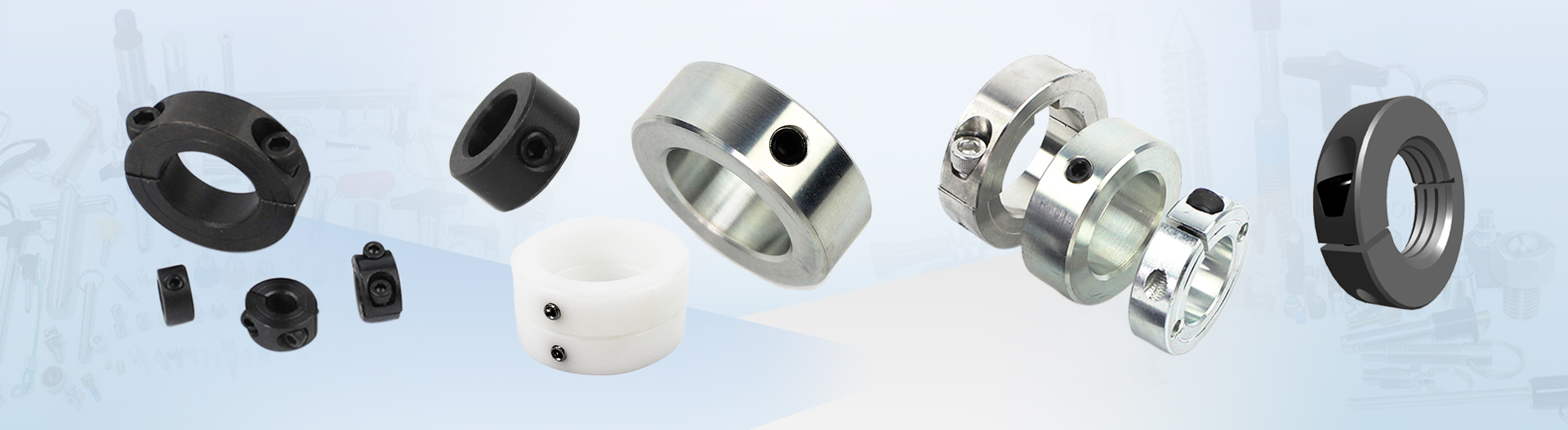

Features of Double Split Shaft Collar

Two Pieces Split Shaft Collar Title:

steel & aluminum double split shaft collars custom shaft collar with keyway for positioning bearings

The locking clamp collar achieves ± 0.01mm radial runout control through a dual split structure, synchronously solving the axial displacement problem of traditional clamping collars;

Advantages of clamping shaft collars:

The Heavy Duty Double Split Shaft Collar is made of forged 420 stainless steel, 304 stainless steel, and nickel plated carbon steel, with a variety of material options, and a tensile strength of up to 1200MPa. Double split design combined with 12.9 level hex screws, providing a large aperture range of 25mm-150mm, with optional phosphating or Dacromet treatment on the surface to meet extreme environmental requirements.

The Sanitary Double Split Shaft Collar can be fully mirror polished, and the double split ring body is made of 316L stainless steel integrated molding. The sealing groove design of the clamping collar is specially optimized, suitable for GMP scenarios such as pharmaceutical filling equipment and dairy pumps;

| Inch-Set Screw Shaft Collar |

|

| Bore | O.D. | Width | Cap Screw |

| 1/8" | 5/8" | 5/16" | 4-40 x 3/8 |

| 3/16" | 5/8" | 5/16" | 4-40 x 3/8 |

| 1/4" | 11/16" | 5/16" | 4-40 x 3/8 |

| 5/16" | 11/16" | 5/16" | 4-40 x 3/8 |

| 3/8" | 7/8" | 3/8" | 6-32 x 3/8 |

| 7/16" | 15/16" | 3/8" | 6-32 x 3/8 |

| 1/2" | 1 1/8" | 13/32" | 8-32 x 1/2 |

| 9/16" | 1 5/16" | 7/16" | 10-32 x 1/2 |

| 5/8" | 1 5/16" | 7/16" | 10-32 x 1/2 |

| 11/16" | 1 1/2" | 1/2" | 10-32 x 1/2 |

| 3/4" | 1 1/2" | 1/2" | 1/4-28 x 5/8 |

| 13/16" | 1 5/8" | 1/2" | 1/4-28 x 5/8 |

| 7/8" | 1 5/8" | 1/2" | 1/4-28 x 5/8 |

| 15/16" | 1 3/4" | 1/2" | 1/4-28 x 5/8 |

| 1" | 1 3/4" | 1/2" | 1/4-28 x 5/8 |

| 1 1/16" | 1 7/8" | 1/2" | 1/4-28 x 5/8 |

| 1 1/8" | 1 7/8" | 1/2" | 1/4-28 x 5/8 |

| 1 3/16" | 2 1/16" | 1/2" | 1/4-28 x 3/4 |

| 1 1/4" | 2 1/16" | 1/2" | 1/4-28 x 3/4 |

| 1 5/16" | 2 1/4" | 9/16" | 1/4-28 x 3/4 |

| 1 3/8" | 2 1/4" | 9/16" | 1/4-28 x 3/4 |

| 1 7/16" | 2 1/4" | 9/16" | 1/4-28 x 3/4 |

| 1 1/2" | 2 3/8" | 9/16" | 1/4-28 x 3/4 |

| 1 9/16" | 2 3/8" | 9/16" | 1/4-28 x 3/4 |

| 1 5/8" | 2 5/8" | 11/16" | 5/16-24 x 1 |

| 1 11/16" | 2 3/4" | 11/16" | 5/16-24 x 1 |

| 1 3/4" | 2 3/4" | 11/16" | 5/16-24 x 1 |

| 1 13/16" | 2 7/8" | 11/16" | 5/16-24 x 1 |

| 1 7/8" | 2 7/8" | 11/16" | 5/16-24 x 1 |

| 1 15/16" | 3" | 11/16" | 5/16-24 x 1 |

| 2" | 3" | 11/16" | 5/16-24 x 1 |

| 2 1/16" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 1/8" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 3/16" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 1/4" | 3 1/4" | 3/4" | 5/16-24 x 1 |

| 2 5/16" | 3 1/2" | 3/4" | 5/16-24 x 1 |

| 2 3/8" | 3 1/2" | 3/4" | 5/16-24 x 1 |

| 2 7/16" | 3 1/2" | 3/4" | 5/16-24 x 1 |

| 2 1/2" | 3 3/4" | 7/8" | 3/8-24 x 1 |

| 2 9/16" | 3 7/8" | 7/8" | 3/8-24 x 1 |

| 2 5/8" | 3 7/8" | 7/8" | 3/8-24 x 1 |

| 2 11/16" | 4" | 7/8" | 3/8-24 x 1 |

| 2 3/4" | 4" | 7/8" | 3/8-24 x 1 |

| 2 7/8" | 4 1/4" | 7/8" | 3/8-24 x 1 |

| 2 15/16" | 4 1/4" | 7/8" | 3/8-24 x 1 |

| 3" | 4 1/4" | 7/8" | 3/8-24 x 1 |

| 3 3/16" | 4 1/2" | 7/8" | 3/8-24 x 1 |

| 3 1/4" | 4 1/2" | 7/8" | 3/8-24 x 1 |

| 3 7/16" | 4 3/4" | 7/8" | 3/8-24 x 1 |

| 3 1/2" | 4 3/4" | 7/8" | 3/8-24 x 1 |

| 3 3/4" | 5" | 7/8" | 3/8-24 x 1 |

| 3 15/16" | 5 1/4" | 7/8" | 3/8-24 x 1 |

| 4" | 5 1/4" | 7/8" | 3/8-24 x 1 |

| 4 1/4" | 5 1/2" | 7/8" | 3/8-24 x 1 |

| 4 7/16" | 5 3/4" | 7/8" | 3/8-24 x 1 |

| 4 1/2" | 5 3/4" | 7/8" | 3/8-24 x 1 |

| 4 15/16" | 6 1/4" | 7/8" | 3/8-24 x 1 |

| 5" | 6 1/4" | 7/8" | 3/8-24 x 1 |

| 5 3/16" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 1/4" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 7/16" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 1/2" | 6 3/4" | 7/8" | 3/8-24 x 1 |

| 5 15/16" | 7 1/4" | 7/8" | 3/8-24 x 1 |

| 6" | 7 1/4" | 7/8" | 3/8-24 x 1 |

| Metric-Single Split Shaft Collar |

|

| Bore | O.D. | Width | Set Screw |

| 3mm | 16mm | 9mm | M3 x 8 |

| 4mm | 16mm | 9mm | M3 x 8 |

| 5mm | 16mm | 9mm | M3 x 8 |

| 6mm | 16mm | 9mm | M3 x 8 |

| 7mm | 18mm | 9mm | M3 x 8 |

| 8mm | 18mm | 9mm | M3 x 10 |

| 9mm | 24mm | 9mm | M3 x 10 |

| 10mm | 24mm | 9mm | M3 x 10 |

| 11mm | 28mm | 11mm | M4 x 12 |

| 12mm | 28mm | 11mm | M4 x 12 |

| 13mm | 30mm | 11mm | M4 x 12 |

| 14mm | 30mm | 11mm | M4 x 12 |

| 15mm | 34mm | 13mm | M5 x 16 |

| 16mm | 34mm | 13mm | M5 x 16 |

| 17mm | 36mm | 13mm | M5 x 16 |

| 18mm | 36mm | 13mm | M5 x 16 |

| 19mm | 40mm | 15mm | M6 x 16 |

| 20mm | 40mm | 15mm | M6 x 16 |

| 21mm | 42mm | 15mm | M6 x 16 |

| 22mm | 42mm | 15mm | M6 x 16 |

| 23mm | 45mm | 15mm | M6 x 16 |

| 24mm | 45mm | 15mm | M6 x 16 |

| 25mm | 45mm | 15mm | M6 x 16 |

| 26mm | 48mm | 15mm | M6 x 16 |

| 27mm | 48mm | 15mm | M6 x 16 |

| 28mm | 48mm | 15mm | M6 x 16 |

| 30mm | 54mm | 15mm | M6 x 16 |

| 32mm | 54mm | 15mm | M6 x 16 |

| 34mm | 57mm | 15mm | M6 x 16 |

| 35mm | 57mm | 15mm | M6 x 16 |

| 36mm | 57mm | 15mm | M6 x 16 |

| 38mm | 60mm | 15mm | M6 x 16 |

| 40mm | 60mm | 15mm | M6 x 16 |

| 42mm | 73mm | 19mm | M8 x 25 |

| 45mm | 73mm | 19mm | M8 x 25 |

| 48mm | 78mm | 19mm | M8 x 25 |

| 50mm | 78mm | 19mm | M8 x 25 |

| 54mm | 82mm | 19mm | M8 x 25 |

| 55mm | 82mm | 19mm | M8 x 25 |

| 60mm | 88mm | 19mm | M8 x 25 |

| 65mm | 93mm | 19mm | M8 x 25 |

| 70mm | 98mm | 19mm | M8 x 25 |

| 75mm | 103mm | 19mm | M8 x 25 |

| 80mm | 108mm | 19mm | M8 x 25 |

Applicable Areas:

Industrial transmission system: used to locate transmission components such as bearings and gears to prevent axial displacement;

Applicable equipment: power transmission shaft systems for conveyors/packaging machinery/textile equipment;

Heavy equipment manufacturing: fixing hydraulic system components in mining/agricultural machinery;

Transportation equipment: fixing the motor shaft end of electric vehicles, positioning the transmission system of motorcycles;

Precision Shaft Collar Customization Workflow:

Requirement confirmation stage:

(inner diameter range: 5-200mm/material: carbon steel/stainless steel/aluminum alloy)

3D drawing docking (supports STEP/IGES format)

CNC machining scheme design (± 0.01mm tolerance control)

Prototype sample production (delivered according to the agreed delivery date)

Surface treatment selection (galvanizing/blackening/passivation treatment)

Batch production (supporting 500-50000 orders) delivery service: customized packaging solutions, logistics tracking and other after-sales services;

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>