Gear Driven Metal Planetary Ring Roller

PDM

| Availability: | |

|---|---|

| Quantity: | |

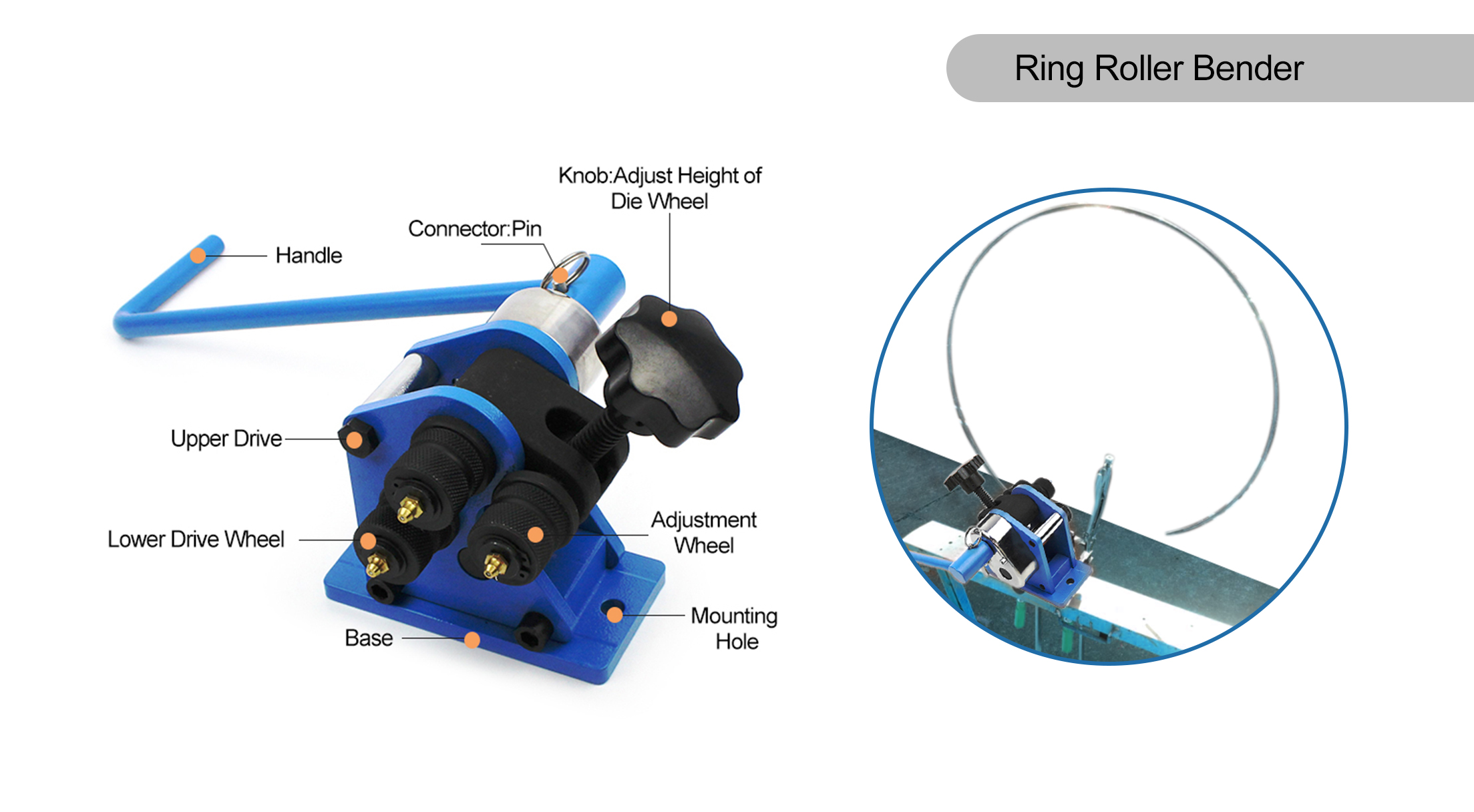

Features of Manual Ring Roller

Tube Ring Roller Title:

Metal Fabrication Parts metal planetary ring roller steel ring roller bending machine for Plant Holders

Core structure and specifications

Roller system

Adopting a three roll symmetrical or four roll linkage design:

Three roll type: the upper roll provides downward pressure (hydraulic drive), and the two lower rolls rotate to provide torque, achieving material curling;

Four roll type (such as automatic coiling machine): The first three rolls are spiral pre bent profiles, and the fourth roll is calibrated and shaped to eliminate extrusion deformation.

The roller material is quenched alloy steel, which can withstand high load impact.

Drive and Control System

The transmission system includes a gearbox, motor, and hydraulic press down device, supporting precise pressure regulation;

Specifications:

Ring Dia.:Create rings from 3" diameter to as large as you need.

Round Steel Capacity: 6.4mm / 1/4inch

Flat Steel Capacity:5X25.4mm / 3/16X1inch

Handle Length:343mm / 13-1/2inch

| Item | Gear Driven Metal Planetary Ring Roller |

| Material | Steel (Heat-treated and hardened) |

| Finish | Powder Coated |

| Process | Stamping, bending, Welding,etc. |

| Ring Dia. | Create rings from 3" diameter to as large as you need. |

| Round Steel Capacity: | 6.4mm / 1/4inch |

| Flat Steel Capacity: | 5X25.4mm / 3/16X1inch |

| Handle Length: | 343mm / 13-1/2inch |

| Color | Blue or Customized |

| Connector | Black Oxide Pin |

| Type | Sheet Metal Fabricaton Components |

| Application | Create Chandeliers,Plant Holders, Ornamental Iron Work and More. |

Application:

Industrial manufacturing: fan blade rings, bridge templates, chemical equipment flanges;

Packaging production: PVC/APET material transparent cylinder, gift packaging tube;

Energy equipment: mining explosion-proof switch housing, cable bracket;

Working principle:

Feed positioning: The profile is automatically fed into the roller gap through the feeding platform;

Pre bending forming: The main roller (three or four rollers) applies radial force, causing the material to undergo elastic deformation → plastic deformation;

Correction and shaping: Fine adjustment of the curvature radius of the last roller;

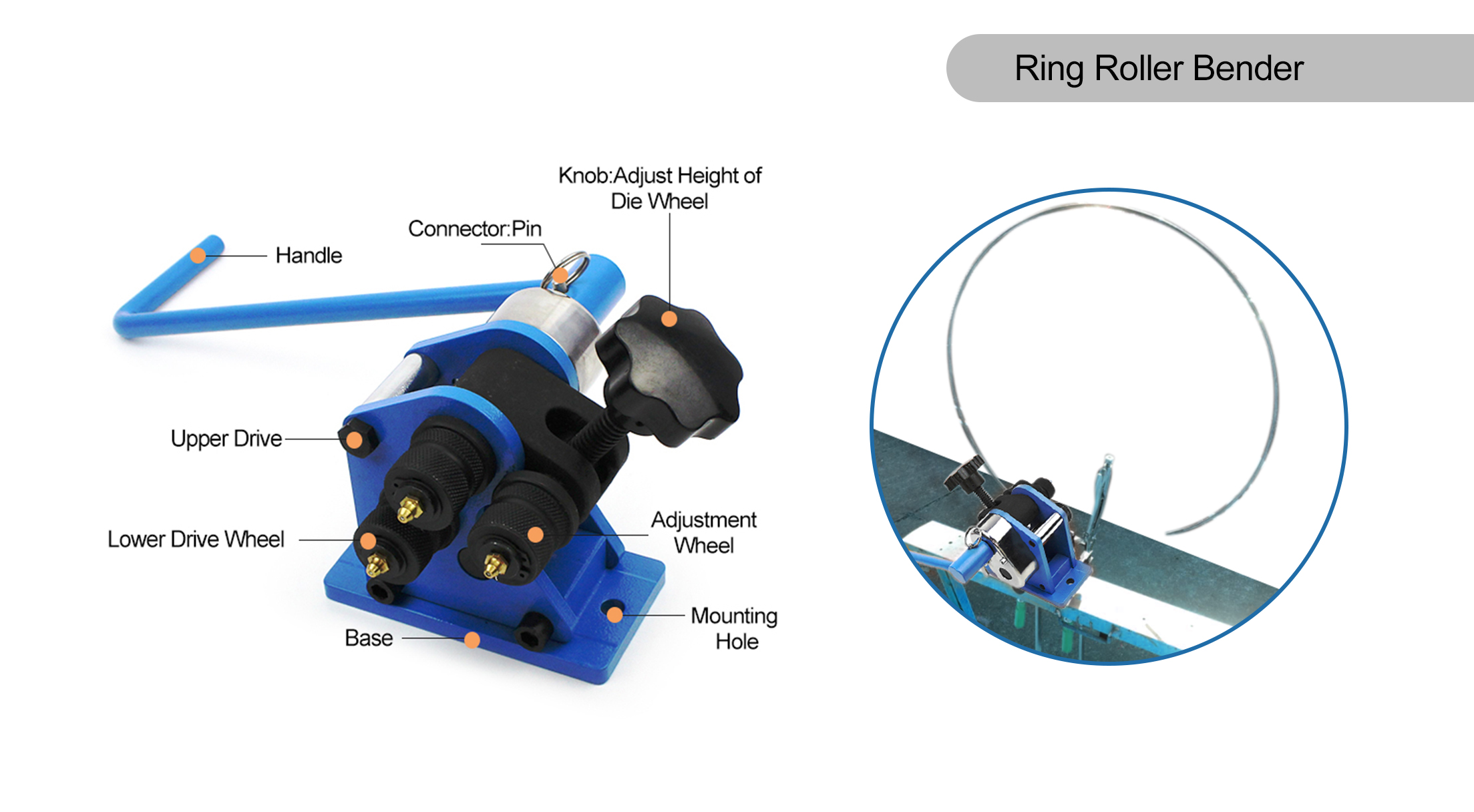

Features of Manual Ring Roller

Tube Ring Roller Title:

Metal Fabrication Parts metal planetary ring roller steel ring roller bending machine for Plant Holders

Core structure and specifications

Roller system

Adopting a three roll symmetrical or four roll linkage design:

Three roll type: the upper roll provides downward pressure (hydraulic drive), and the two lower rolls rotate to provide torque, achieving material curling;

Four roll type (such as automatic coiling machine): The first three rolls are spiral pre bent profiles, and the fourth roll is calibrated and shaped to eliminate extrusion deformation.

The roller material is quenched alloy steel, which can withstand high load impact.

Drive and Control System

The transmission system includes a gearbox, motor, and hydraulic press down device, supporting precise pressure regulation;

Specifications:

Ring Dia.:Create rings from 3" diameter to as large as you need.

Round Steel Capacity: 6.4mm / 1/4inch

Flat Steel Capacity:5X25.4mm / 3/16X1inch

Handle Length:343mm / 13-1/2inch

| Item | Gear Driven Metal Planetary Ring Roller |

| Material | Steel (Heat-treated and hardened) |

| Finish | Powder Coated |

| Process | Stamping, bending, Welding,etc. |

| Ring Dia. | Create rings from 3" diameter to as large as you need. |

| Round Steel Capacity: | 6.4mm / 1/4inch |

| Flat Steel Capacity: | 5X25.4mm / 3/16X1inch |

| Handle Length: | 343mm / 13-1/2inch |

| Color | Blue or Customized |

| Connector | Black Oxide Pin |

| Type | Sheet Metal Fabricaton Components |

| Application | Create Chandeliers,Plant Holders, Ornamental Iron Work and More. |

Application:

Industrial manufacturing: fan blade rings, bridge templates, chemical equipment flanges;

Packaging production: PVC/APET material transparent cylinder, gift packaging tube;

Energy equipment: mining explosion-proof switch housing, cable bracket;

Working principle:

Feed positioning: The profile is automatically fed into the roller gap through the feeding platform;

Pre bending forming: The main roller (three or four rollers) applies radial force, causing the material to undergo elastic deformation → plastic deformation;

Correction and shaping: Fine adjustment of the curvature radius of the last roller;

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>