Lynch Pin

PDM

| Availability: | |

|---|---|

| Quantity: | |

Locking Pins Wire Retainer Title:

Locking Pins Wire Retainer D shape & Round Lynch Pin

Trailer Lynch Pin Introduction:

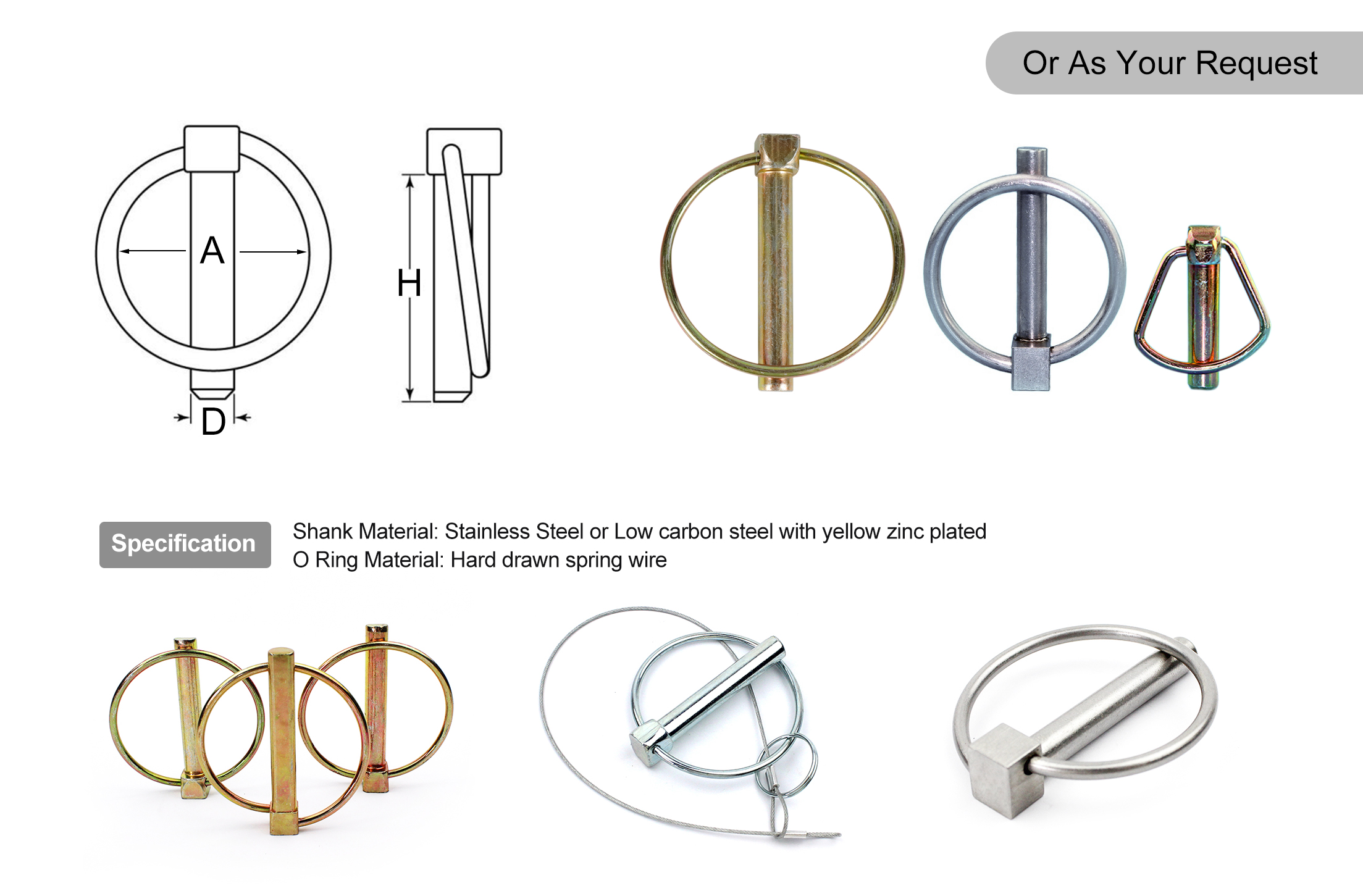

Lynch Pin refers to a type of shaft end fixing pin, commonly in the form of a metal pin with a spring lock, which is inserted into the shaft hole and quickly fastened and disassembled through a locking mechanism (such as a spring ball); Commonly used for agricultural machinery wheel axles and trailer connection devices;

Lynch Pin mainstream materials:

Galvanized carbon steel: The substrate is made of carbon steel, and the surface is treated with galvanizing, which has basic rust prevention ability;

Conventional environments such as agricultural machinery and trailer fixation;

Stainless steel: made of 304/316 stainless steel material, with strong resistance to salt spray corrosion, no risk of coating peeling, and long service life;

High corrosion scenarios such as marine environments and chemical equipment;

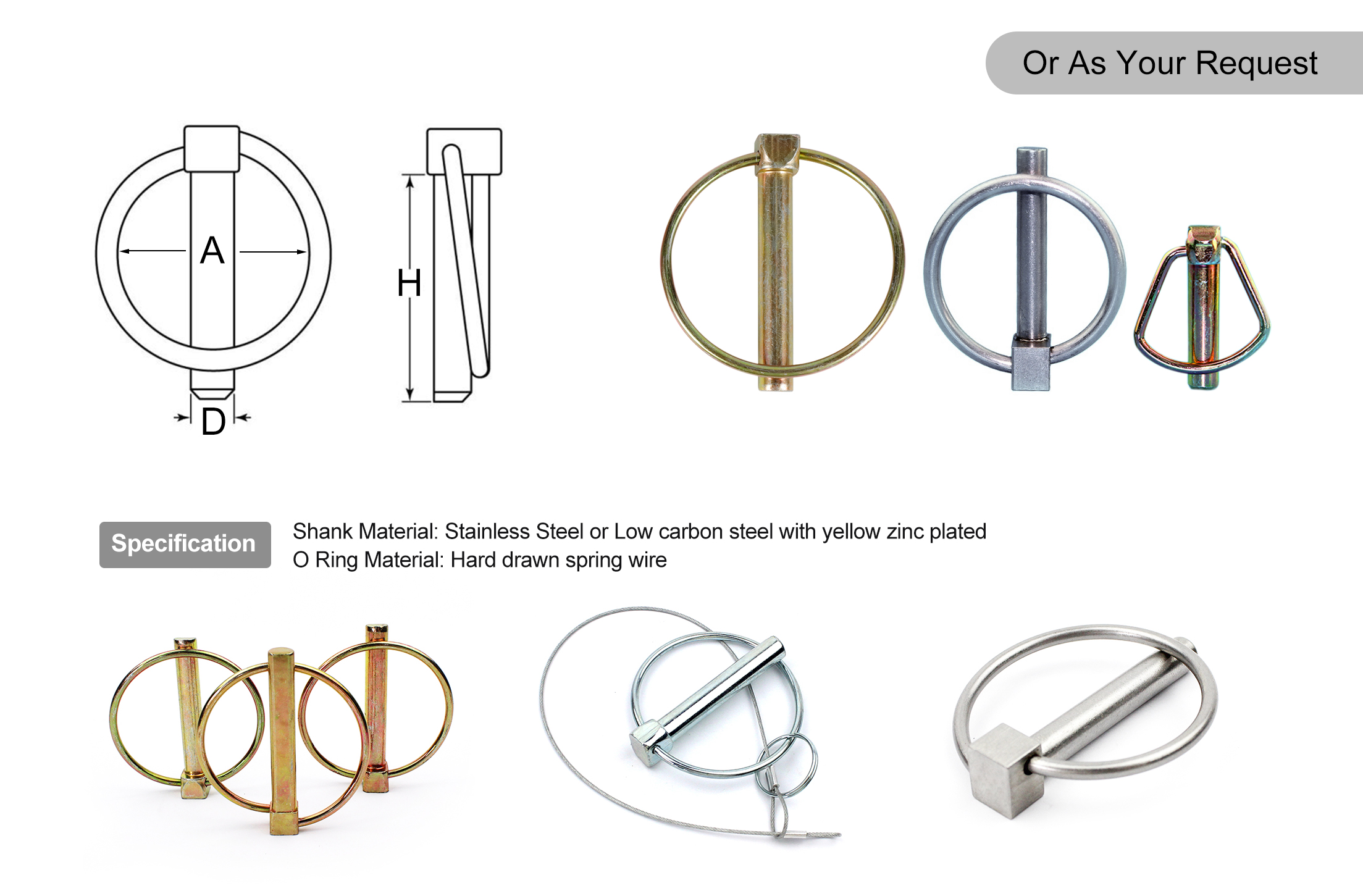

Lock Pin Material:Stainless Steel,Carbon Steel

Surface Treatment:Zinc Plating,Colorful Zinc-Plated or Plaining,etc.

Pin Diameter:1/4”, 5/16", 3/8” and other standard sizes, supporting non-standard customization.

Core functions:

Mechanical anchoring: prevents displacement of rotating components through axial constraints, suitable for dynamic load scenarios;

Anti detachment mechanism: It can only be disassembled by actively applying external force, and its vibration resistance is better than that of ordinary pins;

| Diameter | Dimensions-mm | Weight | ||

| mm | inch | A | H | G |

| 4.5 | 11/64 | 34 | 40 | 20 |

| 6 | 1/4 | 34 | 40 | 24 |

| 6 | 1/4 | 34 | 45 | 25 |

| 8 | 5/16 | 34 | 40 | 30 |

| 8 | 5/16 | 34 | 45 | 32 |

| 9 | 3/8 | 34 | 45 | 39 |

| 10 | 7/16 | 34 | 40 | 42 |

| 10 | 7/16 | 34 | 45 | 45 |

| 11 | 29/64 | 34 | 40 | 45 |

| 11 | 29/64 | 34 | 45 | 50 |

Application:

Heavy equipment transmission shaft fixation, mold guide column positioning, aircraft maintenance panel anchoring, rail vehicle wheelset locking, etc;

Installation steps:

Maintain vertical alignment between the pin body and the axis of the hole, and gently push until the steel ball retracts (do not hammer or tilt insertion);

After hearing the "click" sound, manually pull and test to confirm the lock;

Locking Pins Wire Retainer Title:

Locking Pins Wire Retainer D shape & Round Lynch Pin

Trailer Lynch Pin Introduction:

Lynch Pin refers to a type of shaft end fixing pin, commonly in the form of a metal pin with a spring lock, which is inserted into the shaft hole and quickly fastened and disassembled through a locking mechanism (such as a spring ball); Commonly used for agricultural machinery wheel axles and trailer connection devices;

Lynch Pin mainstream materials:

Galvanized carbon steel: The substrate is made of carbon steel, and the surface is treated with galvanizing, which has basic rust prevention ability;

Conventional environments such as agricultural machinery and trailer fixation;

Stainless steel: made of 304/316 stainless steel material, with strong resistance to salt spray corrosion, no risk of coating peeling, and long service life;

High corrosion scenarios such as marine environments and chemical equipment;

Lock Pin Material:Stainless Steel,Carbon Steel

Surface Treatment:Zinc Plating,Colorful Zinc-Plated or Plaining,etc.

Pin Diameter:1/4”, 5/16", 3/8” and other standard sizes, supporting non-standard customization.

Core functions:

Mechanical anchoring: prevents displacement of rotating components through axial constraints, suitable for dynamic load scenarios;

Anti detachment mechanism: It can only be disassembled by actively applying external force, and its vibration resistance is better than that of ordinary pins;

| Diameter | Dimensions-mm | Weight | ||

| mm | inch | A | H | G |

| 4.5 | 11/64 | 34 | 40 | 20 |

| 6 | 1/4 | 34 | 40 | 24 |

| 6 | 1/4 | 34 | 45 | 25 |

| 8 | 5/16 | 34 | 40 | 30 |

| 8 | 5/16 | 34 | 45 | 32 |

| 9 | 3/8 | 34 | 45 | 39 |

| 10 | 7/16 | 34 | 40 | 42 |

| 10 | 7/16 | 34 | 45 | 45 |

| 11 | 29/64 | 34 | 40 | 45 |

| 11 | 29/64 | 34 | 45 | 50 |

Application:

Heavy equipment transmission shaft fixation, mold guide column positioning, aircraft maintenance panel anchoring, rail vehicle wheelset locking, etc;

Installation steps:

Maintain vertical alignment between the pin body and the axis of the hole, and gently push until the steel ball retracts (do not hammer or tilt insertion);

After hearing the "click" sound, manually pull and test to confirm the lock;

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>