Super Ball Bushing is a high load, self-aligning precision linear motion bearing, which is an upgraded version of the linear ball bushing. Its core advantage is that its load capacity and service life far exceed ordinary linear bearings, while also possessing automatic centering, low friction, and high-speed characteristics. It is the core component of precision linear transmission.

Super Ball Bushing

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Self Aligning Ball Bushing Linear

Super Ball Bushing Title:

self aligning ball bushing linear super ball bushing bearing sba series chrome steel from PDM

Linear Ball Bearing Introduction:

Super Ball Bushing is an industrial grade high-end linear bearing designed for heavy-duty, high-precision, and long-life linear motion scenarios. Its size is fully compatible with standard linear bearings and can directly replace ordinary ball bushings without changing the installation structure. It is the core transmission component of automation equipment, precision machines, and conveyor systems.

Material: Chrome Steel,Aluminum,Stainless Steel, etc

Ball Bushing Type: Closed & Open Type

Modle Number:SBA4UU,SBA6UU,SBA8UU,SBA10UU,SBA12UU,etc

Feature:Self Aligning,High Load Capactiy & Long Life,Low Friction,High Speed and Quiet Operation,etc

Application: CNC machinery,Automation systems,Industrial robotics,Material handling systems

Classification of mainstream product models:

Super Ball Bushing is divided into three major series based on structural form/applicable standards, covering all industrial scenarios:

Closed type (SBE/SB): with two end seals, dustproof and anti fouling, suitable for end support scenarios (such as shaft end positioning);

Open type (SBEO/SBO): no side seal, suitable for continuous support scenarios (such as long axis reciprocating motion);

Axle pillow block type (CS/CSO): integrated installation base, no processing installation, suitable for fast assembly scenarios;

Anti corrosion type: nickel plated jacket+stainless steel ball bearings, suitable for food, chemical, and humid environments.

| Model Number | Size Dimensions | ||||||

| D | B | Tolerance | B1 | Tolerance | B2 | D1 | |

| SBA4 | 0.5 | 0.75 | 0 -0.015 | 0.515 | 0 -0.015 | 0.039 | 0.4687 |

| SBA6 | 0.625 | 0.875 | 0 -0.015 | 0.703 | 0 -0.015 | 0.039 | 0.588 |

| SBA8 | 0.875 | 1.25 | 0 -0.02 | 1.032 | 0 -0.02 | 0.0459 | 0.8209 |

| SBA10 | 1.125 | 1.5 | 0 -0.02 | 1.112 | 0 -0.02 | 0.0559 | 1.059 |

| SBA12 | 1.25 | 1.625 | 0 -0.02 | 1.272 | 0 -0.02 | 0.0559 | 1.176 |

| SBA16 | 1.5625 | 2.25 | 0 -0.02 | 1.886 | 0 -0.02 | 0.0679 | 1.4678 |

| SBA20 | 2 | 2.625 | 0 -0.025 | 2.011 | 0 -0.025 | 0.0679 | 1.8859 |

| SBA24 | 2.375 | 3 | 0 -0.03 | 2.422 | 0 -0.03 | 0.0859 | 2.2389 |

| Model Number | Use Shaft Dia. | Number of Ball Columns | Basic Rated Load | Quality(N) | ||

| d | Tolerance | Moving C(N) | Static C(N) | |||

| SBA4 | 0.25 | 0 -0.0005 | 4 | 265 | 355 | 0.04 |

| SBA6 | 0.375 | 0 -0.0005 | 4 | 420 | 530 | 0.06 |

| SBA8 | 0.5 | 0 -0.0005 | 4 | 1020 | 1290 | 0.19 |

| SBA10 | 0.675 | 0 -0.0005 | 5 | 1780 | 2220 | 0.46 |

| SBA12 | 0.75 | 0 -0.0005 | 6 | 2090 | 2620 | 0.55 |

| SBA16 | 1 | 0 -0.0005 | 6 | 3780 | 4710 | 1.18 |

| SBA20 | 1.25 | 0 -0.0006 | 6 | 5470 | 6800 | 2.16 |

| SBA24 | 1.5 | 0 -0.0006 | 6 | 6580 | 8220 | 3.34 |

Unit:Inch 1inch=25.4mm 1N - 0.102kgf

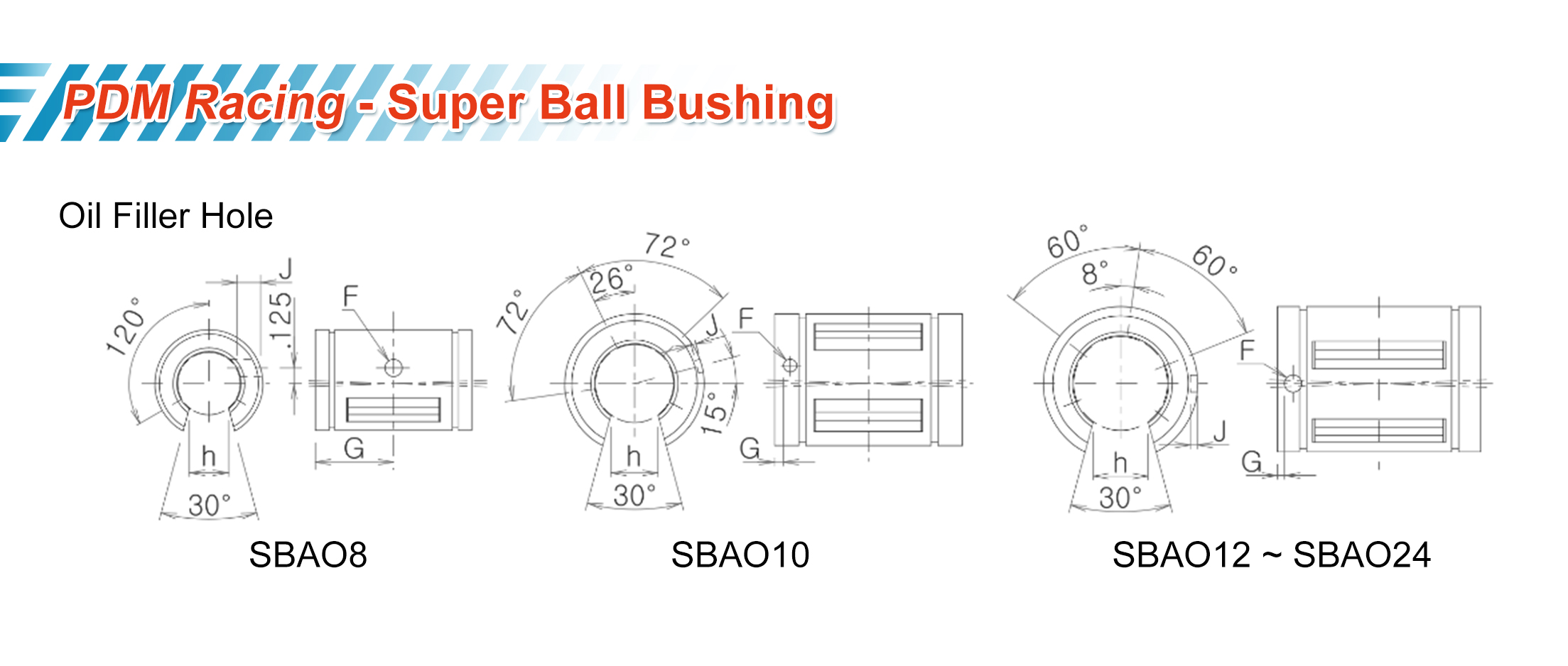

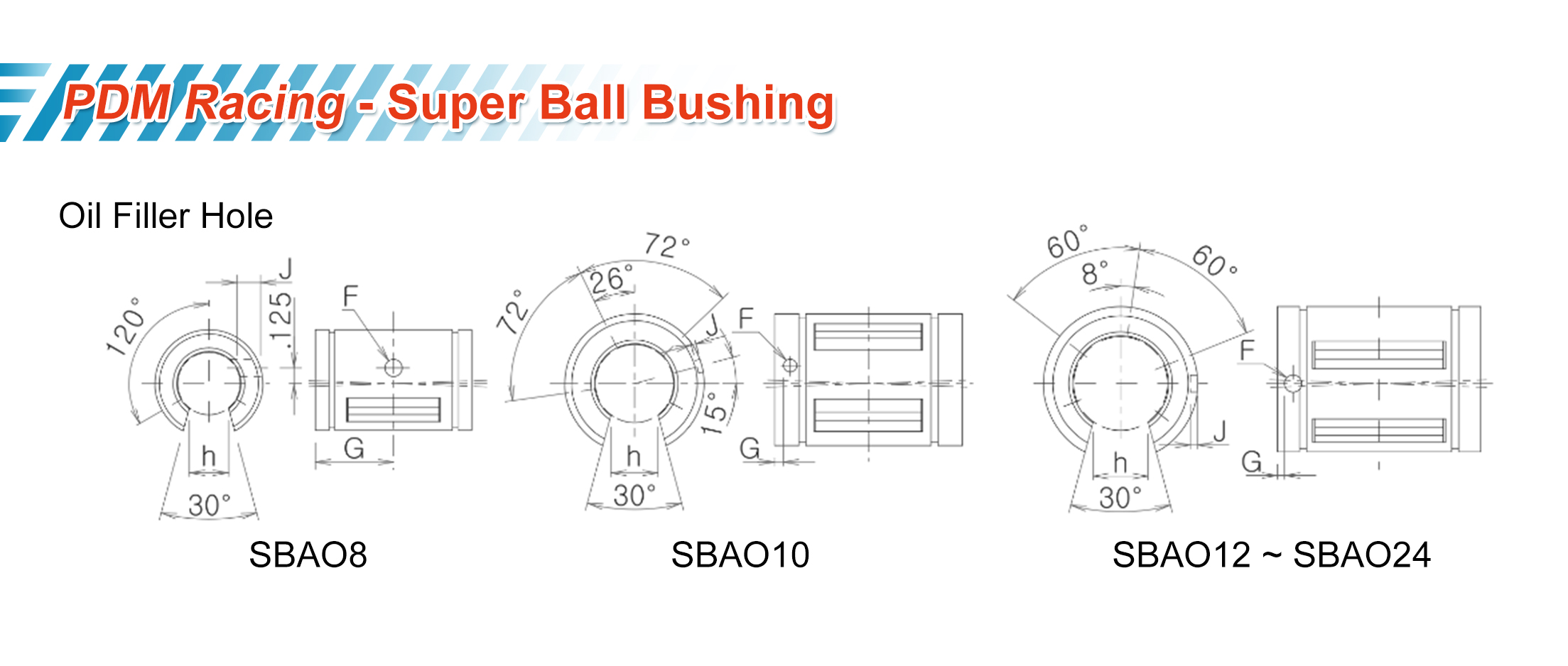

| Model Number | Size Dimensions | |||||||

| D | B | Tolerance | B1 | Tolerance | B2 | D1 | h | |

| SBAO8 | 0.875 | 1.25 | 0 -0.02 | 1.032 | 0 -0.02 | 0.0459 | 0.8209 | 0.313 |

| SBAO10 | 1.125 | 1.5 | 0 -0.02 | 1.112 | 0 -0.02 | 0.0559 | 1.059 | 0.375 |

| SBAO12 | 1.25 | 1.625 | 0 -0.02 | 1.272 | 0 -0.02 | 0.0559 | 1.176 | 0.438 |

| SBAO16 | 1.5625 | 2.25 | 0 -0.02 | 1.886 | 0 -0.02 | 0.0679 | 1.4687 | 0.563 |

| SBAO20 | 2 | 2.625 | 0 -0.025 | 2.011 | 0 -0.025 | 0.0679 | 1.8859 | 0.625 |

| SBAO24 | 2.375 | 3 | 0 -0.03 | 2.422 | 0 -0.03 | 0.0859 | 2.2389 | 0.75 |

| Model Number | Use Shaft Dia. | Oil Filler Hole | Number of Ball Columns | Basic Rated Load | Quality(N) | ||||

| d | Tolerance | F | G | J | Moving C(N) | Static C(N) | |||

| SBAO8 | 0.5 | 0 -0.0005 | 0.136 | 0.625 | Penetrate | 3 | 1020 | 1290 | 0.15 |

| SBAO10 | 0.675 | 0 -0.0005 | 0.105 | 0.125 | 0.039 | 4 | 1780 | 2220 | 0.37 |

| SBAO12 | 0.75 | 0 -0.0005 | 0.136 | 0.125 | 0.059 | 5 | 2090 | 2620 | 0.45 |

| SBAO16 | 1 | 0 -0.0005 | 0.136 | 0.125 | 0.047 | 5 | 3780 | 4710 | 0.98 |

| SBAO20 | 1.25 | 0 -0.0006 | 0.201 | 0.1875 | 0.09 | 5 | 5470 | 6800 | 1.86 |

| SBAO24 | 1.5 | 0 -0.0006 | 0.201 | 0.1875 | 0.09 | 5 | 6580 | 8220 | 2.84 |

Unit:Inch 1inch=25.4mm 1N - 0.102kgf

Application:

Precision machine tools: linear guide pairs for CNC lathes and milling machines, tool magazine transmission mechanisms;

Automation equipment: industrial robotic arms, linear modules, servo slides, sorting conveyor lines;

Testing instruments: coordinate measuring instrument, laser testing equipment, precision positioning platform;

Logistics equipment: Linear transmission components for AGV carts, sorting machines, and palletizing machines;

Medical equipment: medical testing equipment, linear motion mechanism of precision medical robotic arm;

Military/Aviation: Small precision transmission devices (lightweight, high reliability requirements).

Advantage of linear ball bushing

Advantage 1: High load and long lifespan (core selling point)

Advantage 2: Automatic centering, compensating for installation/processing errors

Advantage 3: Ultra low friction, high speed/high acceleration

Advantage 4: Adjustable gap, supports zero gap/pre press assembly

Advantage 5: Size compatibility, directly replacing ordinary bearings

Advantage 6: Wide temperature adaptability, wear resistance, strong adaptability to working conditions

Notes-Ball bushing in other specifications:

SB16UU SB20UU SB25UU SB30UU SB40UU

SBO16UU SBO20UU SBO25UU SBO30UU SBO40UU

SH16UU SH20UU SH25UU SH30UU SH40UU SH45UU

SHW16UU SHW20UU SHW25UU SHW30UU SHW40UU

SH16AUU SH20AUU SH25AUU SH30AUU SH40AUU SH50AUU

SHO16UU SHO20UU SHO25UU SHO30UU SHO35UU SHO40UU

SBE16UU SBE20UU SBE25UU SBE30UU SBE35UU SBE40UU

SBEO16UU SBEO20UU SBEO25UU SBEO30UU SBEO35UU

CS16UU CS20UU CS25UU CS30UU CS40UU CS50UU

MB5C MB5N MB7C MB7N MB7L MB9C MB9N MB9L MB12C MB12N MB12L MB15C MB15N MB15L

M5C M5N M5NA M7C M7N M7L M7LA M9C M9N M9L M9LA M12C M12N M12L M15C M15N M20C M20N M20L

H15F H15FL H20F H20FL H25F H25FL H30F H30FL H35F H35FL H45F H45FL H55F H55FL

H15R H15RL H20R H20RL H25R H25RL H30R H30RL H35R H35RL H45R H45RL H55R H55RL

H15SF H15SFL H20SF H20SFL H25SF H25SFL H30SF H30SFL H35SF H35SFL H45SF H45SFL H55SF H55SFL

H15SR H15SRL H20SR H20SRL H25SR H25SRL H30SR H30SRL H35SR H35SRL H45SR H45SRL H55SR H55SRL

S15C S15R S20C S20R S25C S25R

S15CF S15F S20CF S20F S25CF S25F

S15SC S15SR S20SC S20SR S25SC S25SR

S15SCF S15SF S20SCF S20SF S25SCF S25SF

Linear Bushing Ball Bearing SB25 SB30 SB40 SB25U SB30U SB40U SB25UU SB30UU SB40UU

Features of Self Aligning Ball Bushing Linear

Super Ball Bushing Title:

self aligning ball bushing linear super ball bushing bearing sba series chrome steel from PDM

Linear Ball Bearing Introduction:

Super Ball Bushing is an industrial grade high-end linear bearing designed for heavy-duty, high-precision, and long-life linear motion scenarios. Its size is fully compatible with standard linear bearings and can directly replace ordinary ball bushings without changing the installation structure. It is the core transmission component of automation equipment, precision machines, and conveyor systems.

Material: Chrome Steel,Aluminum,Stainless Steel, etc

Ball Bushing Type: Closed & Open Type

Modle Number:SBA4UU,SBA6UU,SBA8UU,SBA10UU,SBA12UU,etc

Feature:Self Aligning,High Load Capactiy & Long Life,Low Friction,High Speed and Quiet Operation,etc

Application: CNC machinery,Automation systems,Industrial robotics,Material handling systems

Classification of mainstream product models:

Super Ball Bushing is divided into three major series based on structural form/applicable standards, covering all industrial scenarios:

Closed type (SBE/SB): with two end seals, dustproof and anti fouling, suitable for end support scenarios (such as shaft end positioning);

Open type (SBEO/SBO): no side seal, suitable for continuous support scenarios (such as long axis reciprocating motion);

Axle pillow block type (CS/CSO): integrated installation base, no processing installation, suitable for fast assembly scenarios;

Anti corrosion type: nickel plated jacket+stainless steel ball bearings, suitable for food, chemical, and humid environments.

| Model Number | Size Dimensions | ||||||

| D | B | Tolerance | B1 | Tolerance | B2 | D1 | |

| SBA4 | 0.5 | 0.75 | 0 -0.015 | 0.515 | 0 -0.015 | 0.039 | 0.4687 |

| SBA6 | 0.625 | 0.875 | 0 -0.015 | 0.703 | 0 -0.015 | 0.039 | 0.588 |

| SBA8 | 0.875 | 1.25 | 0 -0.02 | 1.032 | 0 -0.02 | 0.0459 | 0.8209 |

| SBA10 | 1.125 | 1.5 | 0 -0.02 | 1.112 | 0 -0.02 | 0.0559 | 1.059 |

| SBA12 | 1.25 | 1.625 | 0 -0.02 | 1.272 | 0 -0.02 | 0.0559 | 1.176 |

| SBA16 | 1.5625 | 2.25 | 0 -0.02 | 1.886 | 0 -0.02 | 0.0679 | 1.4678 |

| SBA20 | 2 | 2.625 | 0 -0.025 | 2.011 | 0 -0.025 | 0.0679 | 1.8859 |

| SBA24 | 2.375 | 3 | 0 -0.03 | 2.422 | 0 -0.03 | 0.0859 | 2.2389 |

| Model Number | Use Shaft Dia. | Number of Ball Columns | Basic Rated Load | Quality(N) | ||

| d | Tolerance | Moving C(N) | Static C(N) | |||

| SBA4 | 0.25 | 0 -0.0005 | 4 | 265 | 355 | 0.04 |

| SBA6 | 0.375 | 0 -0.0005 | 4 | 420 | 530 | 0.06 |

| SBA8 | 0.5 | 0 -0.0005 | 4 | 1020 | 1290 | 0.19 |

| SBA10 | 0.675 | 0 -0.0005 | 5 | 1780 | 2220 | 0.46 |

| SBA12 | 0.75 | 0 -0.0005 | 6 | 2090 | 2620 | 0.55 |

| SBA16 | 1 | 0 -0.0005 | 6 | 3780 | 4710 | 1.18 |

| SBA20 | 1.25 | 0 -0.0006 | 6 | 5470 | 6800 | 2.16 |

| SBA24 | 1.5 | 0 -0.0006 | 6 | 6580 | 8220 | 3.34 |

Unit:Inch 1inch=25.4mm 1N - 0.102kgf

| Model Number | Size Dimensions | |||||||

| D | B | Tolerance | B1 | Tolerance | B2 | D1 | h | |

| SBAO8 | 0.875 | 1.25 | 0 -0.02 | 1.032 | 0 -0.02 | 0.0459 | 0.8209 | 0.313 |

| SBAO10 | 1.125 | 1.5 | 0 -0.02 | 1.112 | 0 -0.02 | 0.0559 | 1.059 | 0.375 |

| SBAO12 | 1.25 | 1.625 | 0 -0.02 | 1.272 | 0 -0.02 | 0.0559 | 1.176 | 0.438 |

| SBAO16 | 1.5625 | 2.25 | 0 -0.02 | 1.886 | 0 -0.02 | 0.0679 | 1.4687 | 0.563 |

| SBAO20 | 2 | 2.625 | 0 -0.025 | 2.011 | 0 -0.025 | 0.0679 | 1.8859 | 0.625 |

| SBAO24 | 2.375 | 3 | 0 -0.03 | 2.422 | 0 -0.03 | 0.0859 | 2.2389 | 0.75 |

| Model Number | Use Shaft Dia. | Oil Filler Hole | Number of Ball Columns | Basic Rated Load | Quality(N) | ||||

| d | Tolerance | F | G | J | Moving C(N) | Static C(N) | |||

| SBAO8 | 0.5 | 0 -0.0005 | 0.136 | 0.625 | Penetrate | 3 | 1020 | 1290 | 0.15 |

| SBAO10 | 0.675 | 0 -0.0005 | 0.105 | 0.125 | 0.039 | 4 | 1780 | 2220 | 0.37 |

| SBAO12 | 0.75 | 0 -0.0005 | 0.136 | 0.125 | 0.059 | 5 | 2090 | 2620 | 0.45 |

| SBAO16 | 1 | 0 -0.0005 | 0.136 | 0.125 | 0.047 | 5 | 3780 | 4710 | 0.98 |

| SBAO20 | 1.25 | 0 -0.0006 | 0.201 | 0.1875 | 0.09 | 5 | 5470 | 6800 | 1.86 |

| SBAO24 | 1.5 | 0 -0.0006 | 0.201 | 0.1875 | 0.09 | 5 | 6580 | 8220 | 2.84 |

Unit:Inch 1inch=25.4mm 1N - 0.102kgf

Application:

Precision machine tools: linear guide pairs for CNC lathes and milling machines, tool magazine transmission mechanisms;

Automation equipment: industrial robotic arms, linear modules, servo slides, sorting conveyor lines;

Testing instruments: coordinate measuring instrument, laser testing equipment, precision positioning platform;

Logistics equipment: Linear transmission components for AGV carts, sorting machines, and palletizing machines;

Medical equipment: medical testing equipment, linear motion mechanism of precision medical robotic arm;

Military/Aviation: Small precision transmission devices (lightweight, high reliability requirements).

Advantage of linear ball bushing

Advantage 1: High load and long lifespan (core selling point)

Advantage 2: Automatic centering, compensating for installation/processing errors

Advantage 3: Ultra low friction, high speed/high acceleration

Advantage 4: Adjustable gap, supports zero gap/pre press assembly

Advantage 5: Size compatibility, directly replacing ordinary bearings

Advantage 6: Wide temperature adaptability, wear resistance, strong adaptability to working conditions

Notes-Ball bushing in other specifications:

SB16UU SB20UU SB25UU SB30UU SB40UU

SBO16UU SBO20UU SBO25UU SBO30UU SBO40UU

SH16UU SH20UU SH25UU SH30UU SH40UU SH45UU

SHW16UU SHW20UU SHW25UU SHW30UU SHW40UU

SH16AUU SH20AUU SH25AUU SH30AUU SH40AUU SH50AUU

SHO16UU SHO20UU SHO25UU SHO30UU SHO35UU SHO40UU

SBE16UU SBE20UU SBE25UU SBE30UU SBE35UU SBE40UU

SBEO16UU SBEO20UU SBEO25UU SBEO30UU SBEO35UU

CS16UU CS20UU CS25UU CS30UU CS40UU CS50UU

MB5C MB5N MB7C MB7N MB7L MB9C MB9N MB9L MB12C MB12N MB12L MB15C MB15N MB15L

M5C M5N M5NA M7C M7N M7L M7LA M9C M9N M9L M9LA M12C M12N M12L M15C M15N M20C M20N M20L

H15F H15FL H20F H20FL H25F H25FL H30F H30FL H35F H35FL H45F H45FL H55F H55FL

H15R H15RL H20R H20RL H25R H25RL H30R H30RL H35R H35RL H45R H45RL H55R H55RL

H15SF H15SFL H20SF H20SFL H25SF H25SFL H30SF H30SFL H35SF H35SFL H45SF H45SFL H55SF H55SFL

H15SR H15SRL H20SR H20SRL H25SR H25SRL H30SR H30SRL H35SR H35SRL H45SR H45SRL H55SR H55SRL

S15C S15R S20C S20R S25C S25R

S15CF S15F S20CF S20F S25CF S25F

S15SC S15SR S20SC S20SR S25SC S25SR

S15SCF S15SF S20SCF S20SF S25SCF S25SF

Linear Bushing Ball Bearing SB25 SB30 SB40 SB25U SB30U SB40U SB25UU SB30UU SB40UU

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>