Welded Elbow Bends

PDM-Racing

| Availability: | |

|---|---|

| Quantity: | |

Features of Welded Elbow Bend

Polished elbow exhaust Title:

Pipe fittings elbow exhaust elbow 90° & 45°&180° bend for Car

Infrastructure

The elbow body is connected to the pipeline through butt welding, and a groove needs to be pre processed to ensure welding quality;

Standard steering angles: 45 ° (diversion), 90 ° (right angle steering), 180 ° (U-shaped return).

Special customization: supports non-standard angles (such as 30 °, 60 °)

International implementation standards: American standard ASME, national standard GB/T, hygiene grade standards: DIN/SMS/3A;

Material types: carbon steel, stainless steel 304/316L, alloy steel, silicone, etc;

Stainless steel elbows Introduction:

Connect the stainless steel elbow to the pipeline through welding (argon arc welding/laser welding) to achieve 45 °, 90 °, 180 ° and other angle turns;

The material is mainly 304/316L stainless steel, containing molybdenum (Mo) element to enhance corrosion resistance;

Silicone Elbow Bends:

Steering angle: Supports standard steering angles such as 30 °, 45 °, 90 °, 135 °, 180 °, etc., to meet different spatial layout requirements;

Multi layer structure: typically designed with 3-5 layers of reinforcement (inner adhesive layer+fiber weaving layer+outer adhesive layer) to enhance compression resistance and durability;

Core processes: compression molding, winding molding;

Curvature classification: long radius (LR), short radius (SR), special curvature, etc;

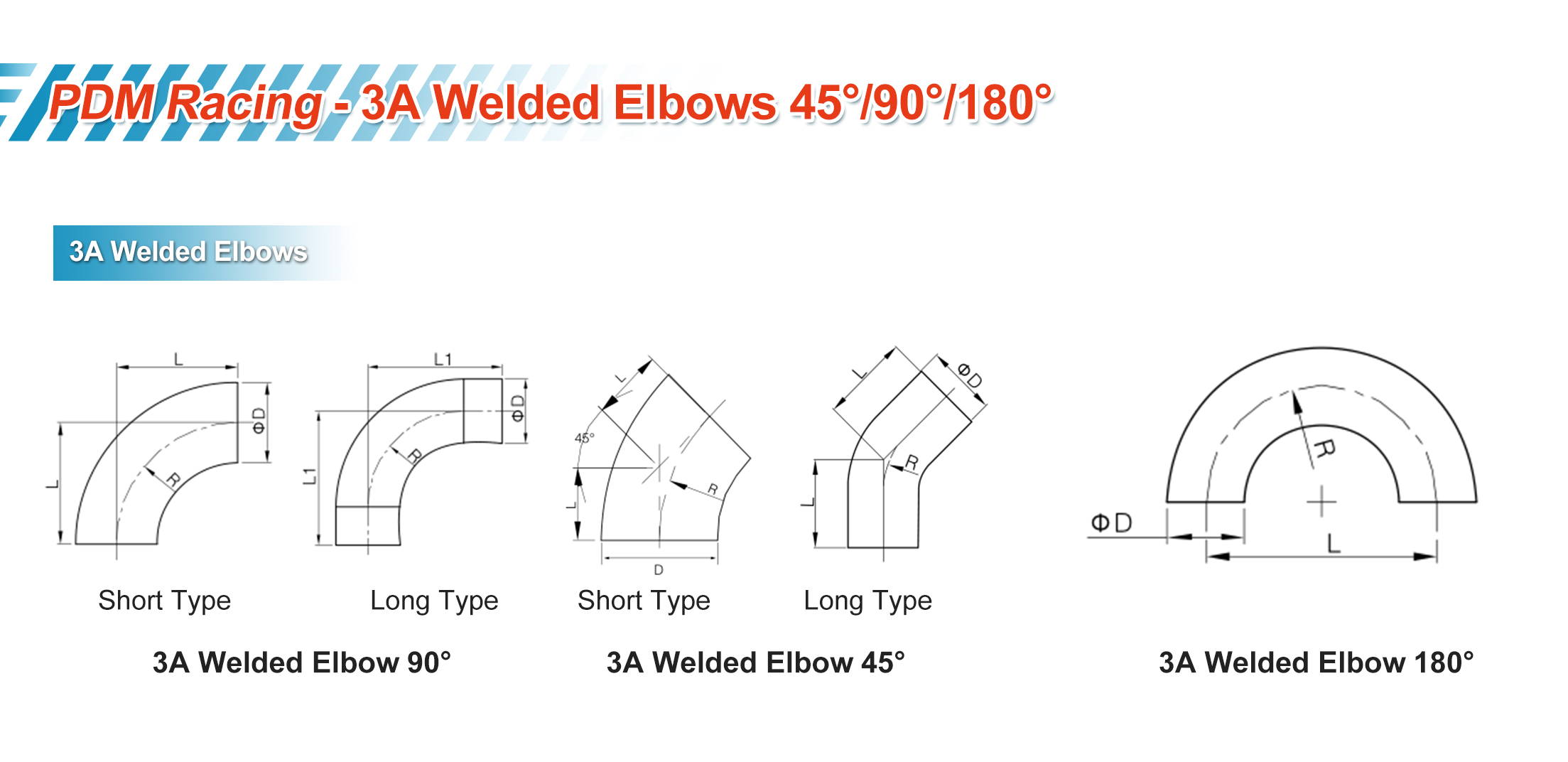

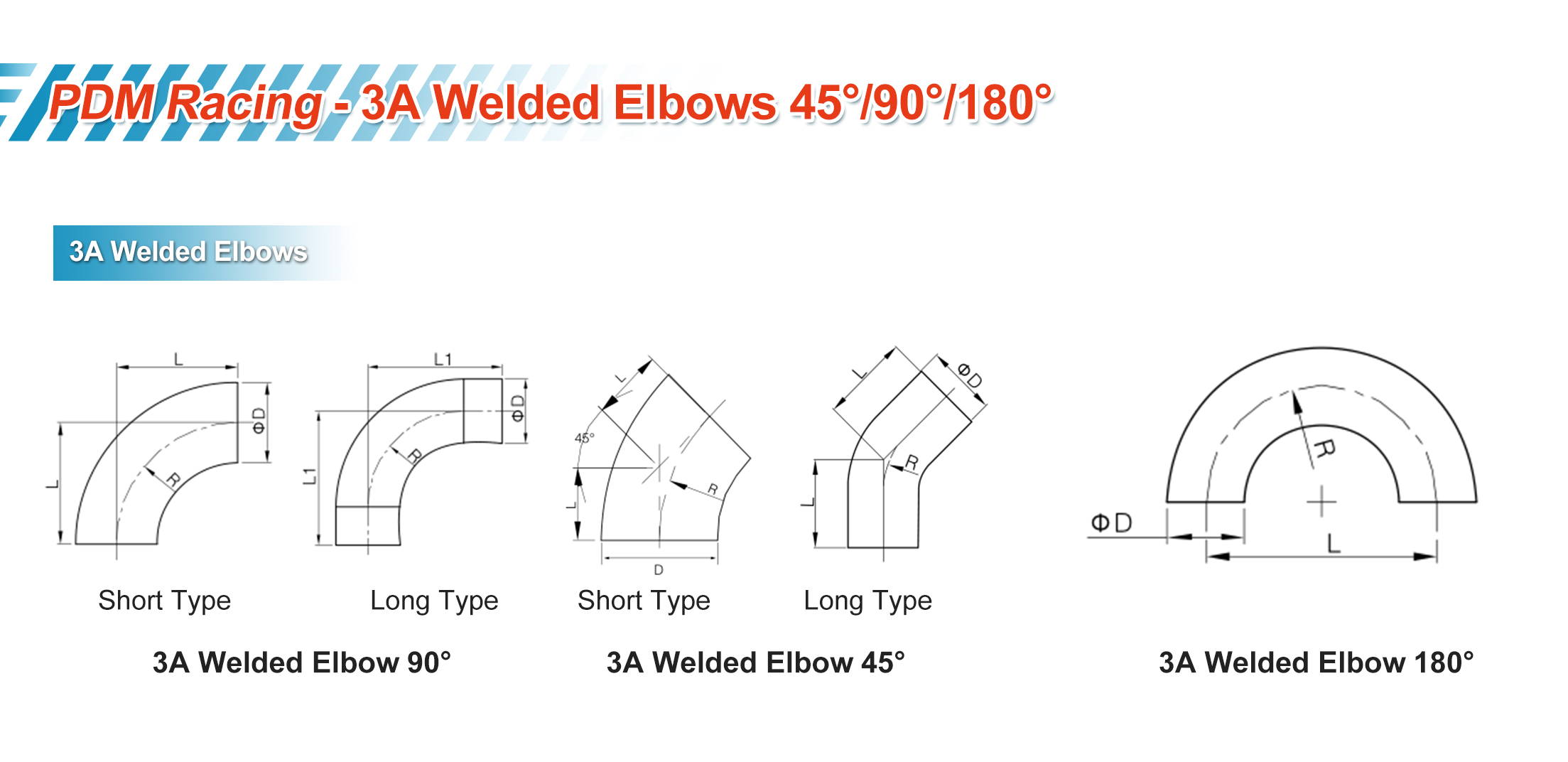

3A Welded Elbow 45 Degree |

|

| Size | D | L | L1 | R |

| 1/2" | 12.7 | 7.9 | 19.3 | 19.1 |

| 3/4" | 19.1 | 11.8 | 19.3 | 28.5 |

| 1" | 25.4 | 15.8 | 30.1 | 38.1 |

| 1 1/4" | 31.8 | 19.8 | 41.3 | 47.7 |

| 1 1/2" | 38.1 | 23.8 | 41.3 | 57.2 |

| 2" | 50.8 | 31.8 | 58.8 | 76.2 |

| 2 1/2" | 63.5 | 39.7 | 76.2 | 95.3 |

| 3" | 76.2 | 47.6 | 93.7 | 114.3 |

| 4" | 101.6 | 63.5 | 122.2 | 152.4 |

| 6" | 152.4 | 94.7 | 158.8 | 228.6 |

3A Welded Elbow 90 Degree |

|

| Size | D | L | L1 | R |

| 1/2" | 12.7 | 19.1 | 38 | 19.1 |

| 3/4" | 19.1 | 28.5 | 38 | 28.5 |

| 1" | 25.4 | 38.1 | 52.4 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 74.6 | 57.2 |

| 2" | 50.8 | 76.2 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 131.8 | 95.3 |

| 3" | 76.2 | 114.3 | 160.3 | 114.3 |

| 4" | 101.6 | 152.4 | 211.1 | 152.4 |

| 6" | 152.4 | 228.6 | 280 | 228.6 |

3A Welded Elbow 180 Degree |

|

| Size | D | L | R |

| 1" | 25.4 | 76.2 | 38.1 |

| 1 1/2" | 38.1 | 114.3 | 57.2 |

| 2" | 50.8 | 152.4 | 76.2 |

| 2 1/2" | 63.5 | 190.5 | 95.3 |

| 3" | 76.2 | 228.6 | 114.3 |

| 4" | 101.6 | 304.8 | 152.4 |

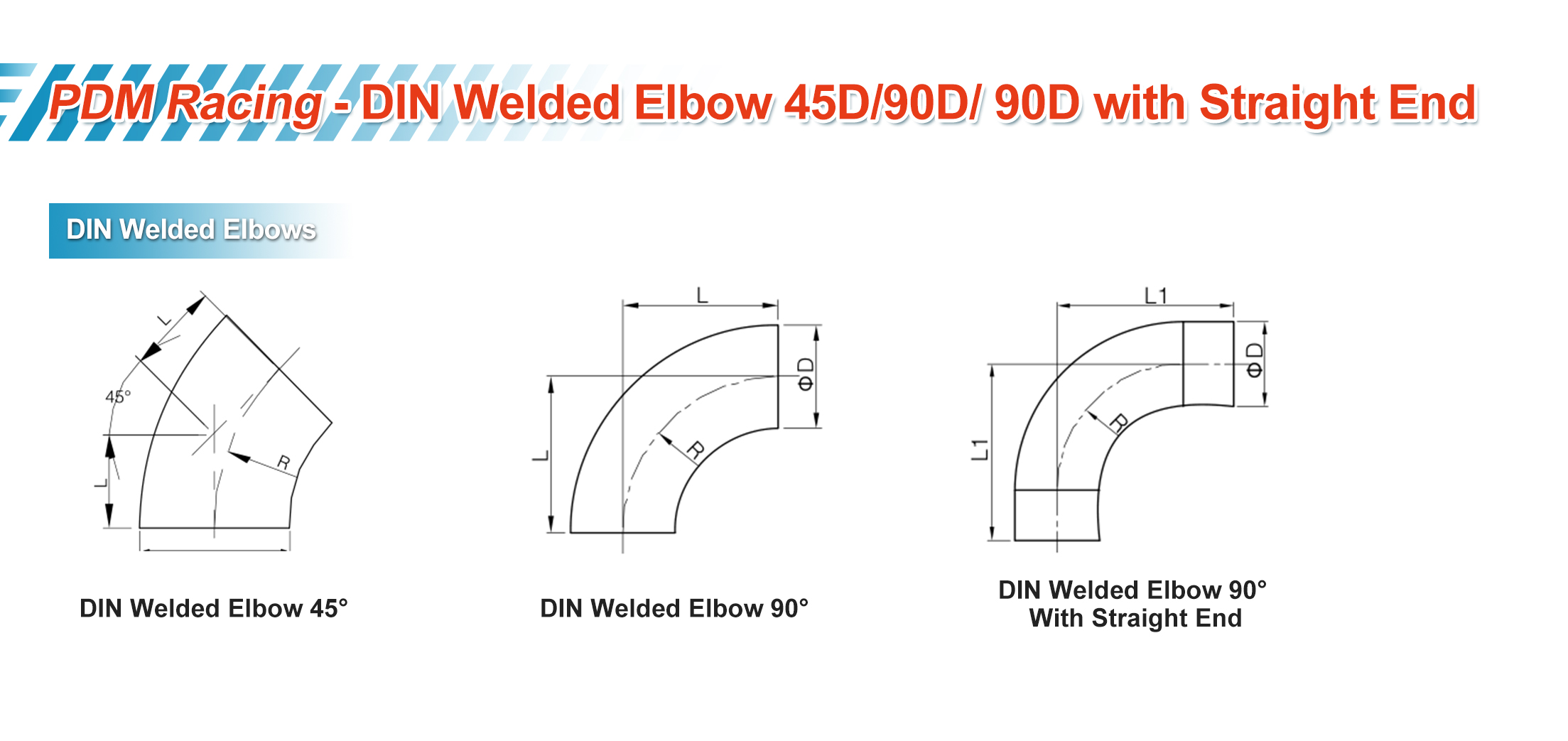

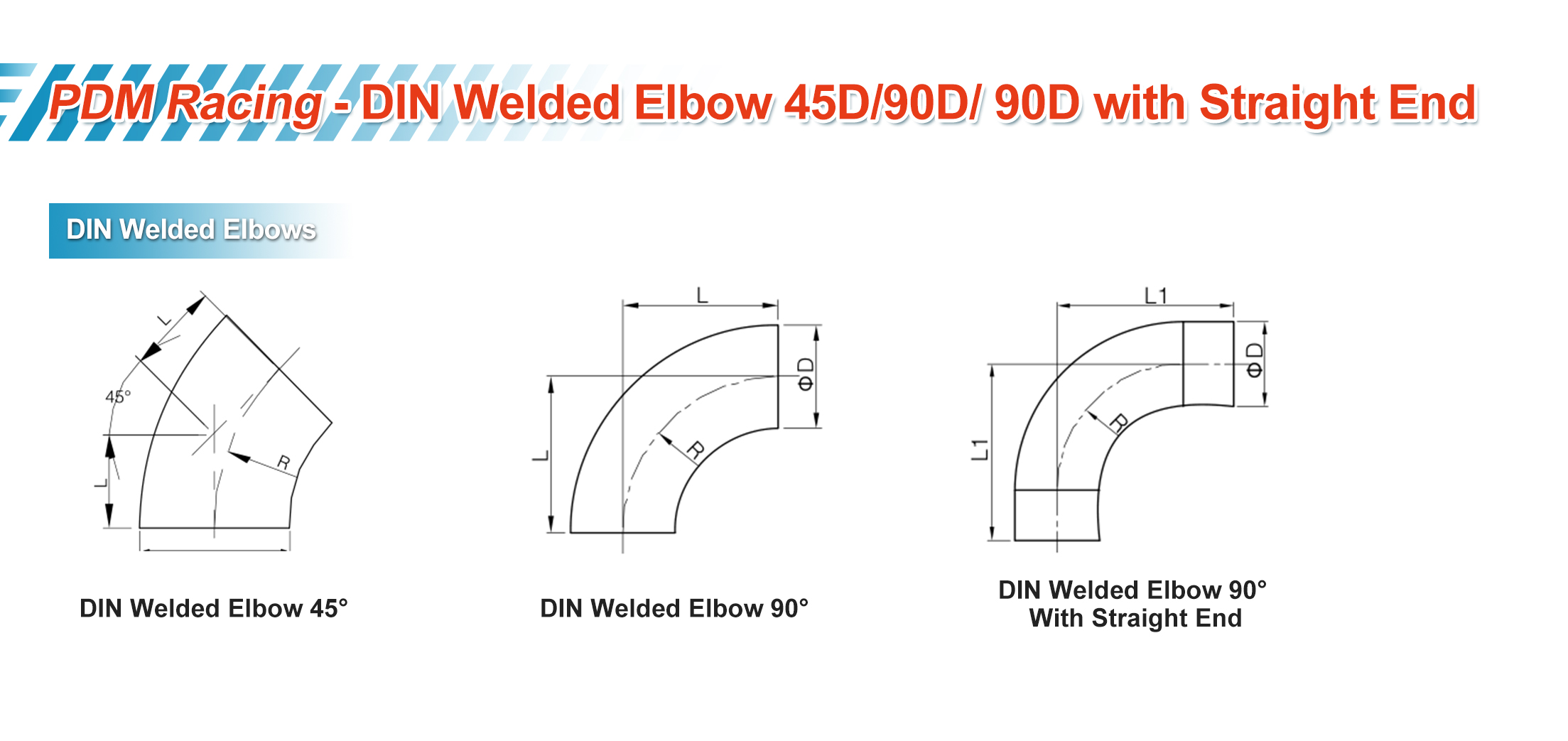

DIN Welded Elbow 45 Degree |

|

| Size | D | L | R |

| DN10 | 12 | 10.7 | 26 |

| DN15 | 18 | 14.5 | 35 |

| DN20 | 22 | 16.5 | 40 |

| DN25 | 28 | 20.7 | 50 |

| DN32 | 34 | 22.8 | 55 |

| DN40 | 40 | 24.8 | 60 |

| DN50 | 52 | 29 | 70 |

| DN65 | 70 | 33.2 | 80 |

| DN80 | 85 | 37.3 | 90 |

| DN100 | 104 | 41.5 | 100 |

| DN125 | 129 | 77.5 | 187 |

| DN150 | 154 | 93.2 | 225 |

DIN Welded Elbow 90 Degree |

|

| Size | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

DIN Welded Elbow 90 Degree With Straight End |

|

| Size | D | L | R |

| DN10 | 12 | 40 | 26 |

| DN15 | 18 | 47 | 35 |

| DN20 | 22 | 52 | 40 |

| DN25 | 28 | 70 | 50 |

| DN32 | 34 | 78 | 55 |

| DN40 | 40 | 85 | 60 |

| DN50 | 52 | 97 | 70 |

| DN65 | 70 | 110 | 80 |

| DN80 | 85 | 118 | 90 |

| DN100 | 104 | 140 | 100 |

| DN125 | 129 | 227 | 187 |

| DN150 | 154 | 265 | 225 |

ISO / IDF Welded Elbow |

|

| Size | D | L | L1 | R |

| 12.7 | 12.7 | 19.1 | 7.9 | 19.1 |

| 19 | 19.1 | 28.5 | 11.8 | 28.5 |

| 25 | 25.4 | 33.5 | 13.9 | 33.5 |

| 32 | 31.8 | 38 | 15.7 | 38 |

| 38 | 38.1 | 48.5 | 20.1 | 48.5 |

| 45 | 45 | 51.5 | 21.3 | 51.5 |

| 51 | 50.8 | 60.5 | 25.5 | 60.5 |

| 57 | 57 | 66 | 27.3 | 66 |

| 63 | 63.5 | 76.5 | 31.6 | 76.5 |

ISO / IDF Welded Elbow |

|

| Size | D | L | L1 | R |

| 76 | 76.2 | 88.9 | 36.7 | 88.9 |

| 89 | 89 | 100 | 42.3 | 100 |

| 102 | 101.6 | 127 | 52.6 | 127 |

| 108 | 108 | 130 | 53.9 | 130 |

| 114.3 | 114.3 | 135 | 55.9 | 135 |

| 133 | 133 | 165 | 68.3 | 165 |

| 159 | 159 | 199 | 82.4 | 199 |

| 204 | 204 | 300 | 124.3 | 300 |

| 219 | 219 | 308 | 126.4 | 302 |

Application:

Energy transmission: long-distance oil and gas pipelines, chemical equipment, marine engineering, turbocharging pipelines, radiator cooling circuits, etc;

Installation steps:

Component inspection: Confirm that the elbow material (carbon steel/stainless steel), angle (45 °, 90 °), and curvature radius (LR/SR) match the pipeline specifications;

Check the integrity of the groove, remove burrs and oil stains;

Space calibration: The deviation between the centerline of the pipeline and the elbow is ≤ 1.5mm to prevent stress concentration after welding;

Long radius elbows (LR) are preferred for use in high-pressure fluid systems.

Features of Welded Elbow Bend

Polished elbow exhaust Title:

Pipe fittings elbow exhaust elbow 90° & 45°&180° bend for Car

Infrastructure

The elbow body is connected to the pipeline through butt welding, and a groove needs to be pre processed to ensure welding quality;

Standard steering angles: 45 ° (diversion), 90 ° (right angle steering), 180 ° (U-shaped return).

Special customization: supports non-standard angles (such as 30 °, 60 °)

International implementation standards: American standard ASME, national standard GB/T, hygiene grade standards: DIN/SMS/3A;

Material types: carbon steel, stainless steel 304/316L, alloy steel, silicone, etc;

Stainless steel elbows Introduction:

Connect the stainless steel elbow to the pipeline through welding (argon arc welding/laser welding) to achieve 45 °, 90 °, 180 ° and other angle turns;

The material is mainly 304/316L stainless steel, containing molybdenum (Mo) element to enhance corrosion resistance;

Silicone Elbow Bends:

Steering angle: Supports standard steering angles such as 30 °, 45 °, 90 °, 135 °, 180 °, etc., to meet different spatial layout requirements;

Multi layer structure: typically designed with 3-5 layers of reinforcement (inner adhesive layer+fiber weaving layer+outer adhesive layer) to enhance compression resistance and durability;

Core processes: compression molding, winding molding;

Curvature classification: long radius (LR), short radius (SR), special curvature, etc;

3A Welded Elbow 45 Degree |

|

| Size | D | L | L1 | R |

| 1/2" | 12.7 | 7.9 | 19.3 | 19.1 |

| 3/4" | 19.1 | 11.8 | 19.3 | 28.5 |

| 1" | 25.4 | 15.8 | 30.1 | 38.1 |

| 1 1/4" | 31.8 | 19.8 | 41.3 | 47.7 |

| 1 1/2" | 38.1 | 23.8 | 41.3 | 57.2 |

| 2" | 50.8 | 31.8 | 58.8 | 76.2 |

| 2 1/2" | 63.5 | 39.7 | 76.2 | 95.3 |

| 3" | 76.2 | 47.6 | 93.7 | 114.3 |

| 4" | 101.6 | 63.5 | 122.2 | 152.4 |

| 6" | 152.4 | 94.7 | 158.8 | 228.6 |

3A Welded Elbow 90 Degree |

|

| Size | D | L | L1 | R |

| 1/2" | 12.7 | 19.1 | 38 | 19.1 |

| 3/4" | 19.1 | 28.5 | 38 | 28.5 |

| 1" | 25.4 | 38.1 | 52.4 | 38.1 |

| 1 1/4" | 31.8 | 47.7 | 69.7 | 47.7 |

| 1 1/2" | 38.1 | 57.2 | 74.6 | 57.2 |

| 2" | 50.8 | 76.2 | 103.2 | 76.2 |

| 2 1/2" | 63.5 | 95.3 | 131.8 | 95.3 |

| 3" | 76.2 | 114.3 | 160.3 | 114.3 |

| 4" | 101.6 | 152.4 | 211.1 | 152.4 |

| 6" | 152.4 | 228.6 | 280 | 228.6 |

3A Welded Elbow 180 Degree |

|

| Size | D | L | R |

| 1" | 25.4 | 76.2 | 38.1 |

| 1 1/2" | 38.1 | 114.3 | 57.2 |

| 2" | 50.8 | 152.4 | 76.2 |

| 2 1/2" | 63.5 | 190.5 | 95.3 |

| 3" | 76.2 | 228.6 | 114.3 |

| 4" | 101.6 | 304.8 | 152.4 |

DIN Welded Elbow 45 Degree |

|

| Size | D | L | R |

| DN10 | 12 | 10.7 | 26 |

| DN15 | 18 | 14.5 | 35 |

| DN20 | 22 | 16.5 | 40 |

| DN25 | 28 | 20.7 | 50 |

| DN32 | 34 | 22.8 | 55 |

| DN40 | 40 | 24.8 | 60 |

| DN50 | 52 | 29 | 70 |

| DN65 | 70 | 33.2 | 80 |

| DN80 | 85 | 37.3 | 90 |

| DN100 | 104 | 41.5 | 100 |

| DN125 | 129 | 77.5 | 187 |

| DN150 | 154 | 93.2 | 225 |

DIN Welded Elbow 90 Degree |

|

| Size | D | L | R |

| DN10 | 12 | 26 | 26 |

| DN15 | 18 | 35 | 35 |

| DN20 | 22 | 40 | 40 |

| DN25 | 28 | 50 | 50 |

| DN32 | 34 | 55 | 55 |

| DN40 | 40 | 60 | 60 |

| DN50 | 52 | 70 | 70 |

| DN65 | 70 | 80 | 80 |

| DN80 | 85 | 90 | 90 |

| DN100 | 104 | 100 | 100 |

| DN125 | 129 | 187 | 187 |

| DN150 | 154 | 225 | 225 |

| DN200 | 204 | 300 | 300 |

DIN Welded Elbow 90 Degree With Straight End |

|

| Size | D | L | R |

| DN10 | 12 | 40 | 26 |

| DN15 | 18 | 47 | 35 |

| DN20 | 22 | 52 | 40 |

| DN25 | 28 | 70 | 50 |

| DN32 | 34 | 78 | 55 |

| DN40 | 40 | 85 | 60 |

| DN50 | 52 | 97 | 70 |

| DN65 | 70 | 110 | 80 |

| DN80 | 85 | 118 | 90 |

| DN100 | 104 | 140 | 100 |

| DN125 | 129 | 227 | 187 |

| DN150 | 154 | 265 | 225 |

ISO / IDF Welded Elbow |

|

| Size | D | L | L1 | R |

| 12.7 | 12.7 | 19.1 | 7.9 | 19.1 |

| 19 | 19.1 | 28.5 | 11.8 | 28.5 |

| 25 | 25.4 | 33.5 | 13.9 | 33.5 |

| 32 | 31.8 | 38 | 15.7 | 38 |

| 38 | 38.1 | 48.5 | 20.1 | 48.5 |

| 45 | 45 | 51.5 | 21.3 | 51.5 |

| 51 | 50.8 | 60.5 | 25.5 | 60.5 |

| 57 | 57 | 66 | 27.3 | 66 |

| 63 | 63.5 | 76.5 | 31.6 | 76.5 |

ISO / IDF Welded Elbow |

|

| Size | D | L | L1 | R |

| 76 | 76.2 | 88.9 | 36.7 | 88.9 |

| 89 | 89 | 100 | 42.3 | 100 |

| 102 | 101.6 | 127 | 52.6 | 127 |

| 108 | 108 | 130 | 53.9 | 130 |

| 114.3 | 114.3 | 135 | 55.9 | 135 |

| 133 | 133 | 165 | 68.3 | 165 |

| 159 | 159 | 199 | 82.4 | 199 |

| 204 | 204 | 300 | 124.3 | 300 |

| 219 | 219 | 308 | 126.4 | 302 |

Application:

Energy transmission: long-distance oil and gas pipelines, chemical equipment, marine engineering, turbocharging pipelines, radiator cooling circuits, etc;

Installation steps:

Component inspection: Confirm that the elbow material (carbon steel/stainless steel), angle (45 °, 90 °), and curvature radius (LR/SR) match the pipeline specifications;

Check the integrity of the groove, remove burrs and oil stains;

Space calibration: The deviation between the centerline of the pipeline and the elbow is ≤ 1.5mm to prevent stress concentration after welding;

Long radius elbows (LR) are preferred for use in high-pressure fluid systems.

content is empty!

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>