Knurled Knob Retractable Spring Plunger

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Knurled Knob Retractable Spring Plunger

Retractable Indexing Plunger Title:

High Positioning Knurled Knob Retractable Spring Plunger

Knurled Knob Retractable Spring Plunger Introduction:

Core Features:

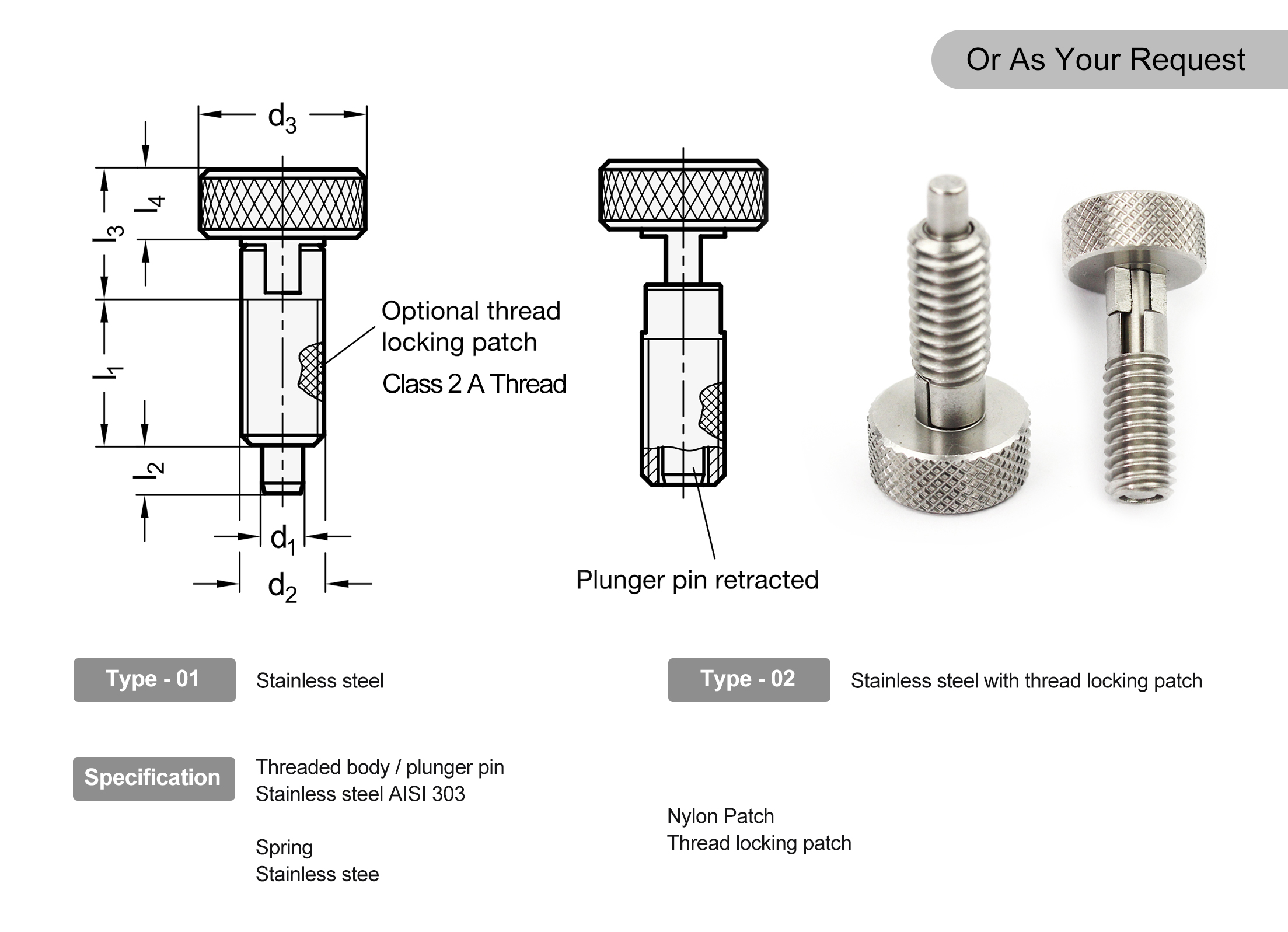

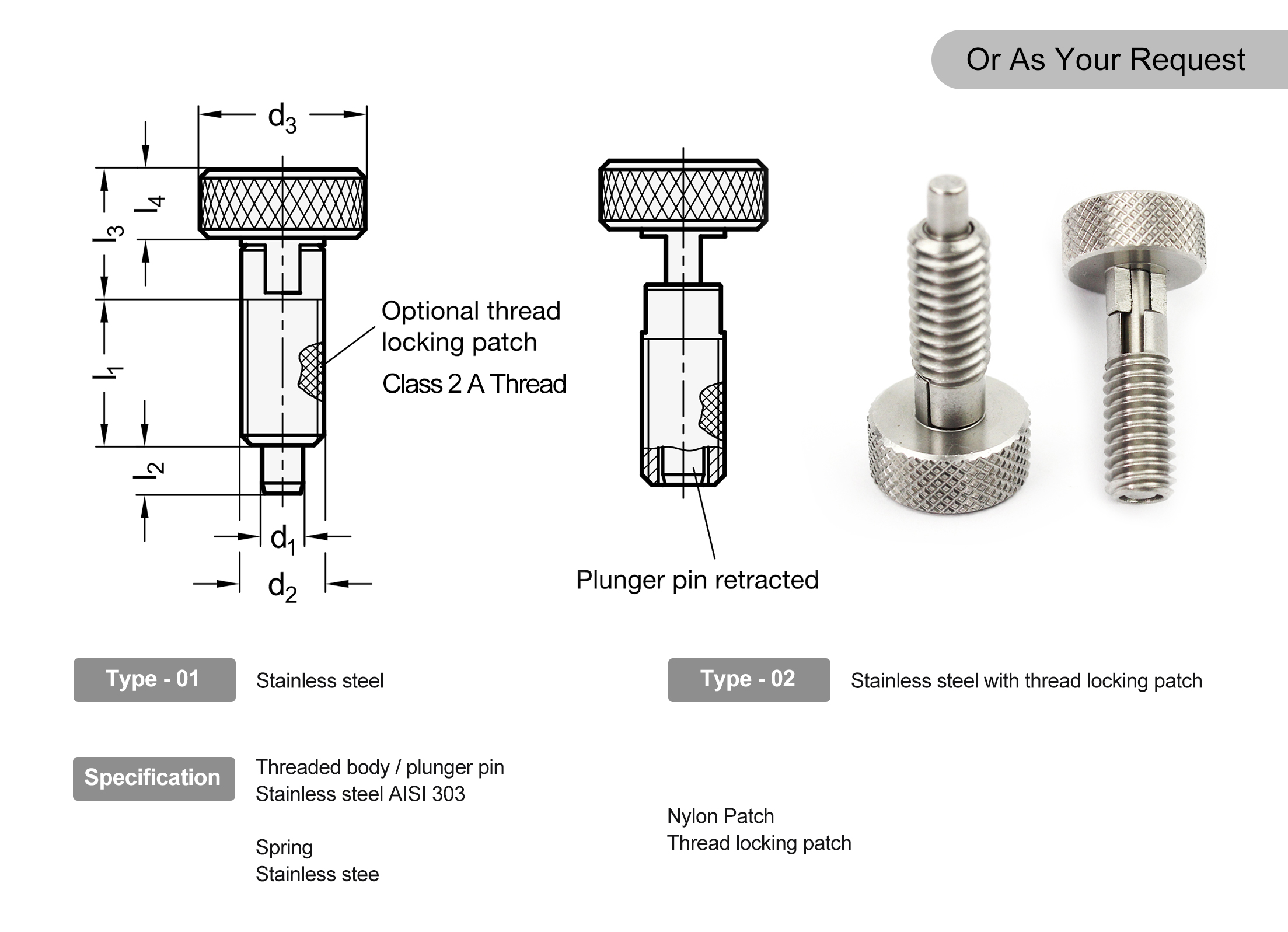

Knurled Knob:

The surface is treated with embossing technology (knorled) to form raised textures or mesh anti slip patterns (such as diamond knorled), greatly improving the friction and anti slip performance of manual operation, suitable for scenarios that require frequent adjustment.

Retractable Spring Plunger:

Composed of a plunger, stainless steel spring, and housing, the plunger retracts when the knob is pressed, and the spring automatically resets after release, achieving rapid positioning and release;

Modle Number:

Operation method: Rotate and press down the rolling knob to trigger plunger contraction/release;

Knob Material: Nickel plated steel (anti slip and wear-resistant);

Piston body: AISI 303 stainless steel (corrosion-resistant);

Thread Size:#10-32,1/4-20,5/16-18,3/8-16,1/2-13

End Pressures Start:0.5lbs,1.0lbs

End Pressures Full:3.0lbs,4.0lbs,6.0lbs,8.0lbs,10.0lbs

| Carbon Steel | Stainless Steel | End Pressures (lbs) | ||||||||

| Part No. | Part No. | Start | Full | Thread | I1 | I2 | d1 | d3 | I3 | I4 |

| KRP010-C | KRP010-S | 0.50 | 3.00 | #10-32 | 0.400 | 0.094 | 0.104 | 0.380 | 0.250 | 0.190 |

| KRP025-C | KRP025-S | 1.00 | 4.00 | 1/4-20 | 0.500 | 0.125 | 0.123 | 0.500 | 0.313 | 0.190 |

| KRP312-C | KRP312-S | 1.00 | 6.00 | 5/16-18 | 0.625 | 0.188 | 0.154 | 0.630 | 0.375 | 0.250 |

| KRP375-C | KRP375-S | 1.00 | 8.00 | 3/8-16 | 0.750 | 0.218 | 0.190 | 0.750 | 0.500 | 0.310 |

| KRP050-C | KRP050-S | 1.00 | 10.0 | 1/2-13 | 0.875 | 0.250 | 0.248 | 1.000 | 0.625 | 0.380 |

Application:

Fine tuning of mold fixtures:

Instrument panel locking;

Automated assembly line;

Core functional advantages:

Anti slip and efficient operation:

The rolling pattern increases the torque transmission efficiency of the knob by 40%, and it can still be operated stably even when wearing gloves or in oily environments.

Quick positioning switch:

Press the knob → retract the plunger → adjust the position of the workpiece → release the knob → insert the plunger into the positioning hole without the need for tools throughout the process.

Anti vibration design:

Spring preloading prevents accidental displacement caused by equipment vibration, and its stability is better than that of standard plungers without locking mechanisms.

Working principle:

The user drives the internal spring plunger to move by rotating or pulling the rolling knob: in an unpressed state, the spring pushes the plunger to extend and lock the target object; When external force is applied (such as pressing or rotating a knob), the plunger retracts into the housing, releasing the lock and facilitating adjustment or disassembly. This design combines the anti slip properties of the rolling knob with the elasticity of the spring plunger, ensuring convenient and precise operation;

Features of Knurled Knob Retractable Spring Plunger

Retractable Indexing Plunger Title:

High Positioning Knurled Knob Retractable Spring Plunger

Knurled Knob Retractable Spring Plunger Introduction:

Core Features:

Knurled Knob:

The surface is treated with embossing technology (knorled) to form raised textures or mesh anti slip patterns (such as diamond knorled), greatly improving the friction and anti slip performance of manual operation, suitable for scenarios that require frequent adjustment.

Retractable Spring Plunger:

Composed of a plunger, stainless steel spring, and housing, the plunger retracts when the knob is pressed, and the spring automatically resets after release, achieving rapid positioning and release;

Modle Number:

Operation method: Rotate and press down the rolling knob to trigger plunger contraction/release;

Knob Material: Nickel plated steel (anti slip and wear-resistant);

Piston body: AISI 303 stainless steel (corrosion-resistant);

Thread Size:#10-32,1/4-20,5/16-18,3/8-16,1/2-13

End Pressures Start:0.5lbs,1.0lbs

End Pressures Full:3.0lbs,4.0lbs,6.0lbs,8.0lbs,10.0lbs

| Carbon Steel | Stainless Steel | End Pressures (lbs) | ||||||||

| Part No. | Part No. | Start | Full | Thread | I1 | I2 | d1 | d3 | I3 | I4 |

| KRP010-C | KRP010-S | 0.50 | 3.00 | #10-32 | 0.400 | 0.094 | 0.104 | 0.380 | 0.250 | 0.190 |

| KRP025-C | KRP025-S | 1.00 | 4.00 | 1/4-20 | 0.500 | 0.125 | 0.123 | 0.500 | 0.313 | 0.190 |

| KRP312-C | KRP312-S | 1.00 | 6.00 | 5/16-18 | 0.625 | 0.188 | 0.154 | 0.630 | 0.375 | 0.250 |

| KRP375-C | KRP375-S | 1.00 | 8.00 | 3/8-16 | 0.750 | 0.218 | 0.190 | 0.750 | 0.500 | 0.310 |

| KRP050-C | KRP050-S | 1.00 | 10.0 | 1/2-13 | 0.875 | 0.250 | 0.248 | 1.000 | 0.625 | 0.380 |

Application:

Fine tuning of mold fixtures:

Instrument panel locking;

Automated assembly line;

Core functional advantages:

Anti slip and efficient operation:

The rolling pattern increases the torque transmission efficiency of the knob by 40%, and it can still be operated stably even when wearing gloves or in oily environments.

Quick positioning switch:

Press the knob → retract the plunger → adjust the position of the workpiece → release the knob → insert the plunger into the positioning hole without the need for tools throughout the process.

Anti vibration design:

Spring preloading prevents accidental displacement caused by equipment vibration, and its stability is better than that of standard plungers without locking mechanisms.

Working principle:

The user drives the internal spring plunger to move by rotating or pulling the rolling knob: in an unpressed state, the spring pushes the plunger to extend and lock the target object; When external force is applied (such as pressing or rotating a knob), the plunger retracts into the housing, releasing the lock and facilitating adjustment or disassembly. This design combines the anti slip properties of the rolling knob with the elasticity of the spring plunger, ensuring convenient and precise operation;

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>