GN611 is an industrial grade spring plunger designed specifically for large displacement buffering and positioning. Its core feature is a long stroke, which can reach 2-3 times the stroke of standard models. It is suitable for precision mechanical scenes that require large-scale flexible contact;

GN611 Long Stroke Spring Plunger

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of GN611 Long Stroke Spring Plunger

GN611 Long Stroke Spring Plunger Title:

spring ball plunger Long Stroke Spring Plunger GN611

Ball Head Plunger Core Feature:

Plunger Tip:

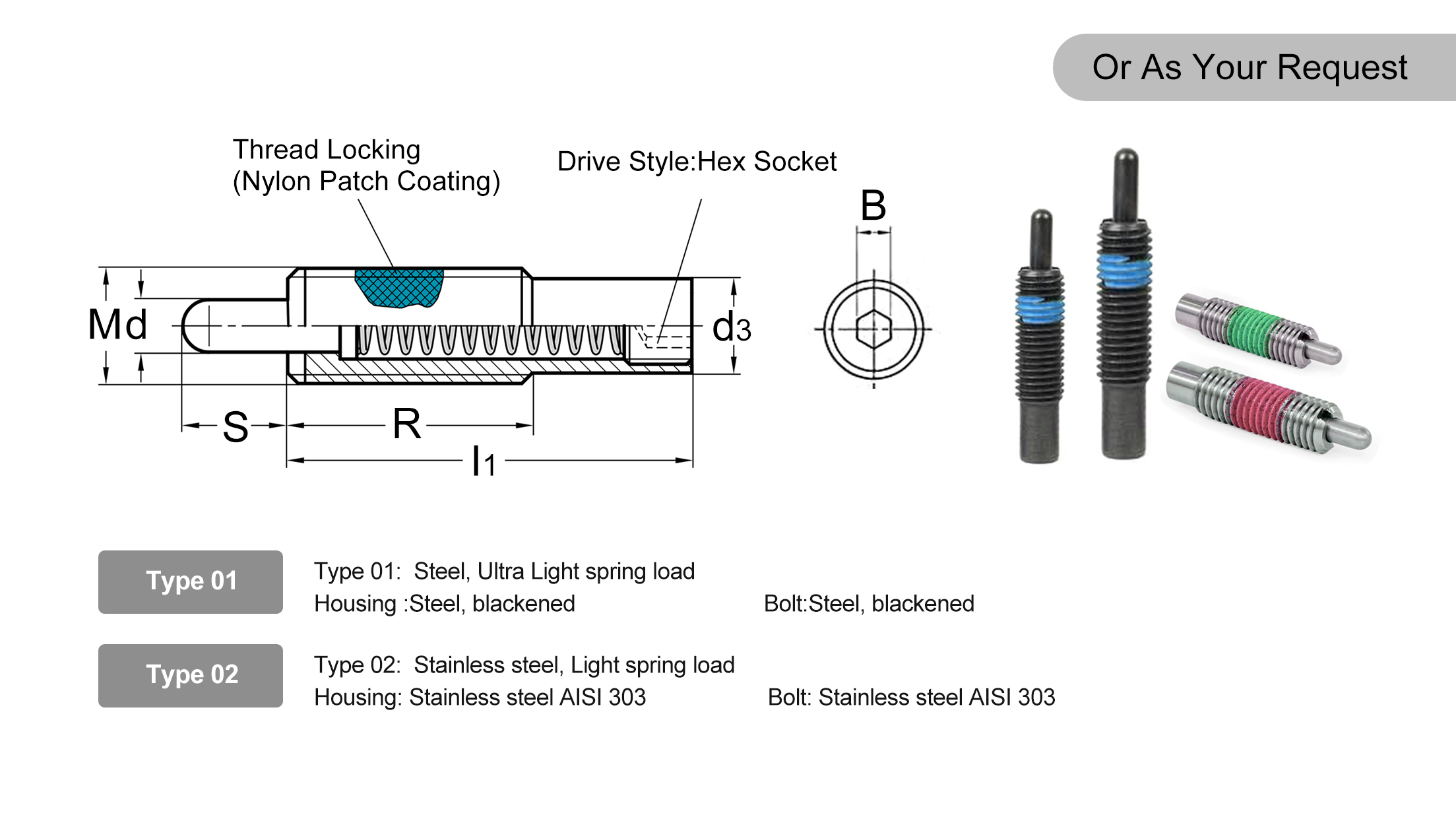

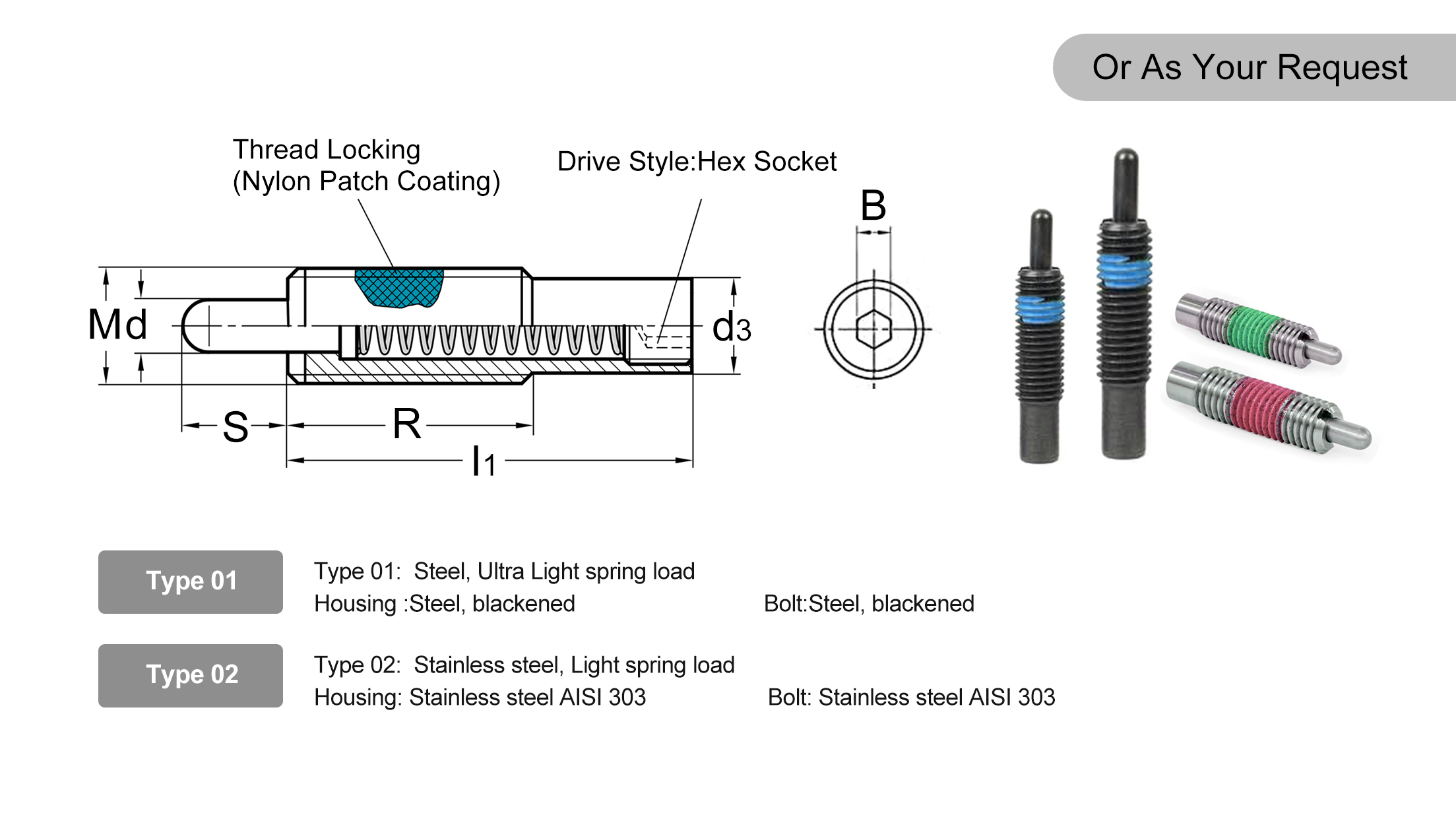

Type 01: Steel, Ultra Light spring load

Housing :Steel, blackened Bolt:Steel, blackened

Type 02: Stainless steel, Light spring load

Housing: Stainless steel AISI 303 Bolt: Stainless steel AISI 303

Thread Size:M3,M4,M5,M6,M8,M10,M16,M20 or As your Request

Long Stroke Exposed Length:1.5mm,3mm,5mm,10mm or Customzied

Long Stroke Diameter:1.1mm,1.6mm,2.0mm,2.5mm,3.1mm,3.8mm or Customized

Internal hex : 0.9mm,1.3mm,2mm,4mm,6mm,10mm or Customized

| M | S(mm) | d(mm) | R(mm) | B | Ultra Light Load(N) | Ultra Light Load(N) | ||

| Min.Load | Max.Load | Min.Load | Max.Load | |||||

| M3 | 1.5 | 1.1 | 10(15) | 0.9 | 0.1 | 0.3 | 0.5 | 1 |

| M3 | 3 | 1.1 | 15(20) | 0.9 | 0.1 | 0.3 | 0.3 | 1 |

| M4 | 2 | 1.6 | 15(24) | 1.3 | 0.2 | 0.7 | 1 | 2 |

| M4 | 4 | 1.6 | 24 | 1.3 | 0.2 | 0.7 | 0.6 | 2 |

| M5 | 3 | 2 | 20(27) | 1.5 | 0.7 | 3 | 2 | 9.8 |

| M5 | 5 | 2 | 27(39) | 1.5 | 0.7 | 3 | 2 | 9.8 |

| M6 | 3 | 2.5 | 25(30) | 2 | 0.9 | 3.2 | 5.9 | 9.8 |

| M6 | 5 | 2.5 | 30(36) | 2 | 0.9 | 3.2 | 2 | 9.8 |

| M6 | 10 | 2.5 | 30 | 2 | - | - | 1.4 | 9.8 |

| M8 | 3 | 3.1 | 25(27) | 2.5 | 0.9 | 3.3 | 5.9 | 9.8 |

| M8 | 5 | 3.1 | 27(30) | 2.5 | 0.9 | 3.3 | 2.9 | 9.8 |

| M8 | 10 | 3.1 | 30 | 2.5 | - | - | 3 | 9.8 |

| M10 | 5 | 3.8 | 30 | 3 | 1.9 | 4.7 | 5.9 | 14.7 |

| M10 | 10 | 3.8 | 30 | 3 | 1.7 | 4.7 | 2.9 | 14.7 |

| M10 | 15 | 3.8 | 30 | 3 | - | - | 2.9 | 14.7 |

| M12 | 5 | 5.5 | 30(35) | 4 | 1.5 | 4.7 | 5.9 | 14.7 |

| M12 | 10 | 5.5 | 35 | 4 | 1.3 | 5.9 | 2.9 | 19.6 |

| M12 | 15 | 5.5 | 35 | 4 | 1.6 | 5.9 | 2.9 | 19.6 |

| M12 | 20 | 5.5 | 35 | 4 | - | - | 3.5 | |

| M | S(mm) | d(mm) | R(mm) | B | Ultra Light Load(N) | Ultra Light Load(N) | ||

| Min.Load | Max.Load | Min.Load | Max.Load | |||||

| M16 | 10 | 8 | 35 | 5 | 1.7 | 13 | 5.9 | 39.2 |

| M16 | 15 | 8 | 35 | 5 | 1.7 | 13 | 3.9 | 39.2 |

| M16 | 20 | 8 | 35 | 5 | 1.7 | 13 | 4.9 | 39.2 |

| M16 | 30 | 8 | 35 | 5 | - | - | 2.9 | 39.2 |

| M16 | 40 | 8 | 35 | 5 | - | - | 4.9 | 39.2 |

| M16 | 50 | 8 | 35 | 5 | - | - | 20 | 49 |

| M16 | 60 | 8 | 35 | 5 | - | - | 2.9 | 49 |

| M16 | 70 | 8 | 35 | 5 | - | - | 3.4 | 49 |

| M16 | 80 | 8 | 35 | 5 | - | - | 20 | 49 |

| M20 | 15 | 10 | 45 | 6 | - | - | 13 | 78.5 |

| M20 | 20 | 10 | 45 | 6 | - | - | 12 | 78.5 |

| M20 | 30 | 10 | 45 | 6 | - | - | 12 | 78.5 |

| M20 | 40 | 10 | 45 | 6 | - | - | 12 | 78.5 |

| M24 | 7 | 10 | 45 | 10 | - | - | 20 | 98.1 |

| M24 | 15 | 10 | 45 | 10 | - | - | 20 | 98.1 |

| M24 | 20 | 10 | 45 | 10 | - | - | 18 | 98.1 |

| M24 | 30 | 10 | 45 | 10 | - | - | 18 | 98.1 |

| M24 | 40 | 10 | 45 | 10 | - | - | 18 | 98.1 |

| M30 | 15 | 14 | 45 | 14 | - | - | 28 | 118 |

| M30 | 20 | 14 | 45 | 14 | - | - | 28 | 118 |

| M30 | 30 | 14 | 45 | 14 | - | - | 28 | 118 |

| M30 | 40 | 14 | 45 | 14 | - | - | 28 | 118 |

Customization Services

Material Combinations: Flexible selection of body, ball, and spring materials;

Dimensions & Parameters: Adjustable body diameter, ball size, and spring force to meet non-standard requirements

Automated production line indexing, precision mold clamping, heavy machinery buffering, etc.

The Advantage of GN611 Long Stroke Spring Plunger:

Long range adaptability:

Supports 1.5-40mm expansion and contraction, used for positioning with large fluctuations in workpiece thickness.

Dual level load design:

Ultra light loading type: Min. Load (0.1N-1.7N)&Max. Load (0.3N-13N)

Light loading type: Min. Load (0.5N-28N)&Max. Load (1N-118N)

Environmental resistance:

Stainless steel version is resistant to acidic and alkaline environments.

Ball Plunger Spring Loaded Key points for installation and maintenance

Pre installation inspection

Confirm that the plunger model matches the installation hole size, and check that the spring is not deformed or stuck.

Clean the installation holes and surrounding areas, remove oil stains and debris, and ensure that the contact surface is dry and flat.

Snap on installation

Align the plunger vertically with the mounting hole (with the groove facing outward), and apply pressure evenly with your thumb until the buckle locks with a "click" sound.

Do not use hammers or hard objects to strike, to avoid plastic buckles breaking.

Notes:

Fault handling

Stuck without resetting: Remove the plunger and check for foreign objects embedded; If the spring is corroded, replace it as a whole.

Unexpected detachment: Confirm that the installation hole is worn;

Features of GN611 Long Stroke Spring Plunger

GN611 Long Stroke Spring Plunger Title:

spring ball plunger Long Stroke Spring Plunger GN611

Ball Head Plunger Core Feature:

Plunger Tip:

Type 01: Steel, Ultra Light spring load

Housing :Steel, blackened Bolt:Steel, blackened

Type 02: Stainless steel, Light spring load

Housing: Stainless steel AISI 303 Bolt: Stainless steel AISI 303

Thread Size:M3,M4,M5,M6,M8,M10,M16,M20 or As your Request

Long Stroke Exposed Length:1.5mm,3mm,5mm,10mm or Customzied

Long Stroke Diameter:1.1mm,1.6mm,2.0mm,2.5mm,3.1mm,3.8mm or Customized

Internal hex : 0.9mm,1.3mm,2mm,4mm,6mm,10mm or Customized

| M | S(mm) | d(mm) | R(mm) | B | Ultra Light Load(N) | Ultra Light Load(N) | ||

| Min.Load | Max.Load | Min.Load | Max.Load | |||||

| M3 | 1.5 | 1.1 | 10(15) | 0.9 | 0.1 | 0.3 | 0.5 | 1 |

| M3 | 3 | 1.1 | 15(20) | 0.9 | 0.1 | 0.3 | 0.3 | 1 |

| M4 | 2 | 1.6 | 15(24) | 1.3 | 0.2 | 0.7 | 1 | 2 |

| M4 | 4 | 1.6 | 24 | 1.3 | 0.2 | 0.7 | 0.6 | 2 |

| M5 | 3 | 2 | 20(27) | 1.5 | 0.7 | 3 | 2 | 9.8 |

| M5 | 5 | 2 | 27(39) | 1.5 | 0.7 | 3 | 2 | 9.8 |

| M6 | 3 | 2.5 | 25(30) | 2 | 0.9 | 3.2 | 5.9 | 9.8 |

| M6 | 5 | 2.5 | 30(36) | 2 | 0.9 | 3.2 | 2 | 9.8 |

| M6 | 10 | 2.5 | 30 | 2 | - | - | 1.4 | 9.8 |

| M8 | 3 | 3.1 | 25(27) | 2.5 | 0.9 | 3.3 | 5.9 | 9.8 |

| M8 | 5 | 3.1 | 27(30) | 2.5 | 0.9 | 3.3 | 2.9 | 9.8 |

| M8 | 10 | 3.1 | 30 | 2.5 | - | - | 3 | 9.8 |

| M10 | 5 | 3.8 | 30 | 3 | 1.9 | 4.7 | 5.9 | 14.7 |

| M10 | 10 | 3.8 | 30 | 3 | 1.7 | 4.7 | 2.9 | 14.7 |

| M10 | 15 | 3.8 | 30 | 3 | - | - | 2.9 | 14.7 |

| M12 | 5 | 5.5 | 30(35) | 4 | 1.5 | 4.7 | 5.9 | 14.7 |

| M12 | 10 | 5.5 | 35 | 4 | 1.3 | 5.9 | 2.9 | 19.6 |

| M12 | 15 | 5.5 | 35 | 4 | 1.6 | 5.9 | 2.9 | 19.6 |

| M12 | 20 | 5.5 | 35 | 4 | - | - | 3.5 | |

| M | S(mm) | d(mm) | R(mm) | B | Ultra Light Load(N) | Ultra Light Load(N) | ||

| Min.Load | Max.Load | Min.Load | Max.Load | |||||

| M16 | 10 | 8 | 35 | 5 | 1.7 | 13 | 5.9 | 39.2 |

| M16 | 15 | 8 | 35 | 5 | 1.7 | 13 | 3.9 | 39.2 |

| M16 | 20 | 8 | 35 | 5 | 1.7 | 13 | 4.9 | 39.2 |

| M16 | 30 | 8 | 35 | 5 | - | - | 2.9 | 39.2 |

| M16 | 40 | 8 | 35 | 5 | - | - | 4.9 | 39.2 |

| M16 | 50 | 8 | 35 | 5 | - | - | 20 | 49 |

| M16 | 60 | 8 | 35 | 5 | - | - | 2.9 | 49 |

| M16 | 70 | 8 | 35 | 5 | - | - | 3.4 | 49 |

| M16 | 80 | 8 | 35 | 5 | - | - | 20 | 49 |

| M20 | 15 | 10 | 45 | 6 | - | - | 13 | 78.5 |

| M20 | 20 | 10 | 45 | 6 | - | - | 12 | 78.5 |

| M20 | 30 | 10 | 45 | 6 | - | - | 12 | 78.5 |

| M20 | 40 | 10 | 45 | 6 | - | - | 12 | 78.5 |

| M24 | 7 | 10 | 45 | 10 | - | - | 20 | 98.1 |

| M24 | 15 | 10 | 45 | 10 | - | - | 20 | 98.1 |

| M24 | 20 | 10 | 45 | 10 | - | - | 18 | 98.1 |

| M24 | 30 | 10 | 45 | 10 | - | - | 18 | 98.1 |

| M24 | 40 | 10 | 45 | 10 | - | - | 18 | 98.1 |

| M30 | 15 | 14 | 45 | 14 | - | - | 28 | 118 |

| M30 | 20 | 14 | 45 | 14 | - | - | 28 | 118 |

| M30 | 30 | 14 | 45 | 14 | - | - | 28 | 118 |

| M30 | 40 | 14 | 45 | 14 | - | - | 28 | 118 |

Customization Services

Material Combinations: Flexible selection of body, ball, and spring materials;

Dimensions & Parameters: Adjustable body diameter, ball size, and spring force to meet non-standard requirements

Automated production line indexing, precision mold clamping, heavy machinery buffering, etc.

The Advantage of GN611 Long Stroke Spring Plunger:

Long range adaptability:

Supports 1.5-40mm expansion and contraction, used for positioning with large fluctuations in workpiece thickness.

Dual level load design:

Ultra light loading type: Min. Load (0.1N-1.7N)&Max. Load (0.3N-13N)

Light loading type: Min. Load (0.5N-28N)&Max. Load (1N-118N)

Environmental resistance:

Stainless steel version is resistant to acidic and alkaline environments.

Ball Plunger Spring Loaded Key points for installation and maintenance

Pre installation inspection

Confirm that the plunger model matches the installation hole size, and check that the spring is not deformed or stuck.

Clean the installation holes and surrounding areas, remove oil stains and debris, and ensure that the contact surface is dry and flat.

Snap on installation

Align the plunger vertically with the mounting hole (with the groove facing outward), and apply pressure evenly with your thumb until the buckle locks with a "click" sound.

Do not use hammers or hard objects to strike, to avoid plastic buckles breaking.

Notes:

Fault handling

Stuck without resetting: Remove the plunger and check for foreign objects embedded; If the spring is corroded, replace it as a whole.

Unexpected detachment: Confirm that the installation hole is worn;

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>