Press Fit Ball Plunger with Flanges

PDM

| Availability: | |

|---|---|

| Quantity: | |

Features of Press Fit Ball Plunger with Flanges

Press Fit Ball Plunger with Flanges Title:

Push Fit Ball Plunger Stainless Steel Ball Spring Plunger with Flanges

Ball Head Plunger Core Feature:

Its core feature is the flange structure, installed at the head or base of the plunger to prevent the plunger from being completely pressed into the hole or accidentally falling off by external forces, ensuring stability and safety.

Commonly used in scenarios that require quick installation and high resistance to vibration, such as mold fixtures or equipment panels.

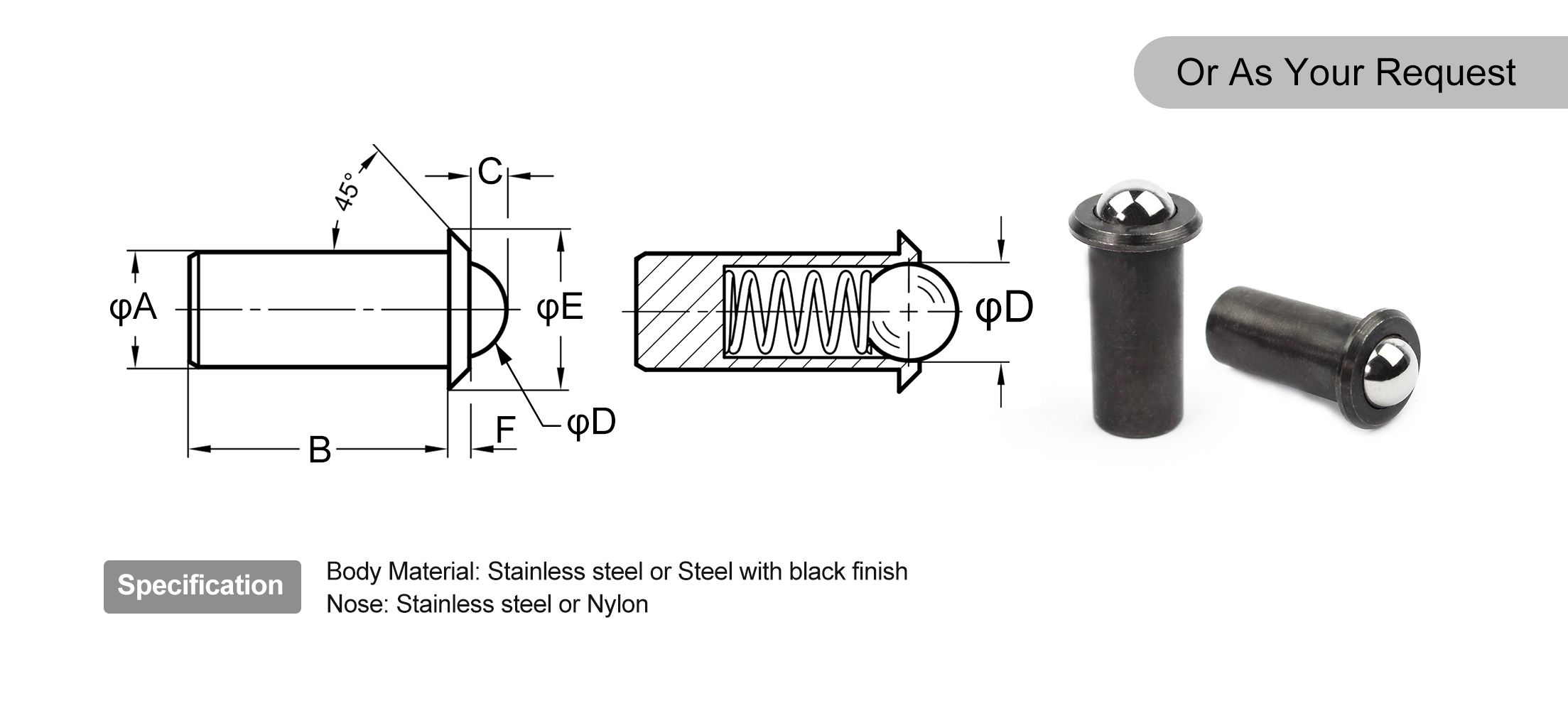

Body Material:Stainless steel or Steel with black finish

Ball Material: Stainless steel or Nylon

Spring:Stainless steel or high-carbon steel with anti-rust treatment.

Surface Finish:Smooth or Plaining,etc.

Housing Diameter:0.125inch、0.188inch、0.250inch、0.312inch or Customzied

Ball Diameter:0.094inch、0.156inch、0.187inch or Customized

Exposed Length:0.035inch、0.058inch or Customized (Corresponding shell diameter)

Installation Type:Press Fit

End Force.LBS:Init. [N~](0.4N-4N) &Final[N~](1.3N-9N) or according to the different demand of customers.

| A(inch) | B(inch) | C(inch) | D(inch) | E(inch) | F(inch) | End Force LBS Init. | End Force LBS Final |

| 0.125 | 0.252 | 0.035 | 0.094 | 0.187 | 0.032 | 0.4 | 1.3 |

| 0.188 | 0.394 | 0.058 | 0.156 | 0.250 | 0.040 | 1 | 2.5 |

| 0.250 | 0.471 | 0.070 | 0.187 | 0.312 | 0.045 | 1.5 | 3.5 |

| 0.312 | 0.643 | 0.090 | 0.250 | 0.375 | 0.045 | 2 | 5 |

| 0.375 | 0.786 | 0.110 | 0.312 | 0.500 | 0.078 | 2.5 | 7 |

| 0.500 | 1.100 | 0.161 | 0.437 | 0.688 | 0.110 | 4 | 9 |

Ball Plunger Spring Loaded Advantage:

Press Fit installation

Directly press into a non threaded optical hole through interference fit, relying on the frictional force between the outer shell and the hole wall for fixation, suitable for soft substrates such as aluminum, plastic, wood, etc;

Flanges design

The bottom of the plunger has an annular flange to prevent the plunger from completely sinking into the hole when compressed, ensuring that the ball head maintains an effective working height.

Elastic positioning mechanism

The built-in spring allows the ball head to retract under pressure and automatically reset after release, achieving buffering, limiting, or intermittent positioning functions.

Customization Services

Material Combinations: Flexible selection of body, ball, and spring materials;

Dimensions & Parameters: Adjustable body diameter, ball size, and spring force to meet non-standard requirements

Lightweight machinery positioning, electronic product assembly, automation equipment buffering, etc;

Advatage of Spring Ball Plunger :

No welding/no threading design: using Press Fit cold connection technology, directly pressing into the pre machined hole position without welding or threading.

By providing high clamping force through elastic deformation of the ball, the connection stability is maintained even under vibration or impact.

Features of Press Fit Ball Plunger with Flanges

Press Fit Ball Plunger with Flanges Title:

Push Fit Ball Plunger Stainless Steel Ball Spring Plunger with Flanges

Ball Head Plunger Core Feature:

Its core feature is the flange structure, installed at the head or base of the plunger to prevent the plunger from being completely pressed into the hole or accidentally falling off by external forces, ensuring stability and safety.

Commonly used in scenarios that require quick installation and high resistance to vibration, such as mold fixtures or equipment panels.

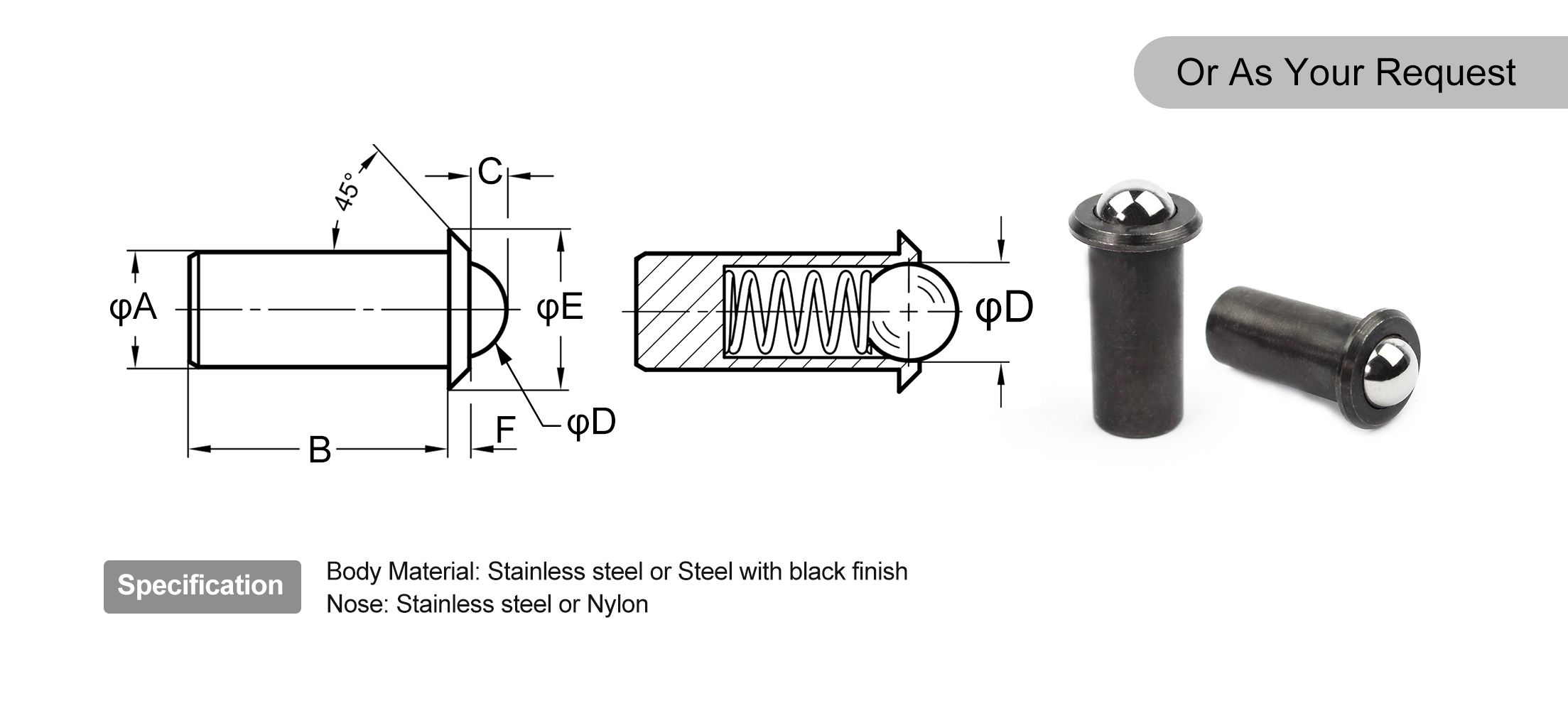

Body Material:Stainless steel or Steel with black finish

Ball Material: Stainless steel or Nylon

Spring:Stainless steel or high-carbon steel with anti-rust treatment.

Surface Finish:Smooth or Plaining,etc.

Housing Diameter:0.125inch、0.188inch、0.250inch、0.312inch or Customzied

Ball Diameter:0.094inch、0.156inch、0.187inch or Customized

Exposed Length:0.035inch、0.058inch or Customized (Corresponding shell diameter)

Installation Type:Press Fit

End Force.LBS:Init. [N~](0.4N-4N) &Final[N~](1.3N-9N) or according to the different demand of customers.

| A(inch) | B(inch) | C(inch) | D(inch) | E(inch) | F(inch) | End Force LBS Init. | End Force LBS Final |

| 0.125 | 0.252 | 0.035 | 0.094 | 0.187 | 0.032 | 0.4 | 1.3 |

| 0.188 | 0.394 | 0.058 | 0.156 | 0.250 | 0.040 | 1 | 2.5 |

| 0.250 | 0.471 | 0.070 | 0.187 | 0.312 | 0.045 | 1.5 | 3.5 |

| 0.312 | 0.643 | 0.090 | 0.250 | 0.375 | 0.045 | 2 | 5 |

| 0.375 | 0.786 | 0.110 | 0.312 | 0.500 | 0.078 | 2.5 | 7 |

| 0.500 | 1.100 | 0.161 | 0.437 | 0.688 | 0.110 | 4 | 9 |

Ball Plunger Spring Loaded Advantage:

Press Fit installation

Directly press into a non threaded optical hole through interference fit, relying on the frictional force between the outer shell and the hole wall for fixation, suitable for soft substrates such as aluminum, plastic, wood, etc;

Flanges design

The bottom of the plunger has an annular flange to prevent the plunger from completely sinking into the hole when compressed, ensuring that the ball head maintains an effective working height.

Elastic positioning mechanism

The built-in spring allows the ball head to retract under pressure and automatically reset after release, achieving buffering, limiting, or intermittent positioning functions.

Customization Services

Material Combinations: Flexible selection of body, ball, and spring materials;

Dimensions & Parameters: Adjustable body diameter, ball size, and spring force to meet non-standard requirements

Lightweight machinery positioning, electronic product assembly, automation equipment buffering, etc;

Advatage of Spring Ball Plunger :

No welding/no threading design: using Press Fit cold connection technology, directly pressing into the pre machined hole position without welding or threading.

By providing high clamping force through elastic deformation of the ball, the connection stability is maintained even under vibration or impact.

PDM's custom screws and components, including non-standard screws, custom stainless steel screws, and thumb screws, have been recognized by a Spanish client in the pumps systems and solutions industry. The client visited PDM to secure multi-category cooperation, focusing on stainless steel Beverage mixer accessories and Stainless Steel Gas Manifold Fitting. The long-term partnership between the two parties is based on PDM's competitive costs, stable quality, fast delivery, and professional service. PDM looks forward to expanding cooperation with more customers from Spain and Europe.

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

There are 23 common plastic molding processes, including injection molding, extrusion molding, rotary molding, blow molding, vacuum forming, compression molding, rolling molding, foam molding, winding molding, lamination molding, film covering molding, pouring molding, drip molding, cold pressing mo

The common materials for engineering plastics are generally as follows:ABS,PP,PC,AS,PS,PE,PPO,HIPS,PMMA,PVC,PC+ABS,GPPS,POM,PA,ASA,PBT,etc.ABS Product Characteristics:● Material & Surface● Texture & Color: Matte or semi-gloss finish, commonly in ivory white or black; supports multi-color appeara

What are the types of commonly used screw head and groove types?Head shape name:Flat Countersunk Head、100deg Flat Countersunk Head、Oval Countersunk Head、Countersunk Trim Head Screws、Fillister Head、 Pan Head、Truss Head,Round Head,etc.Slot type name:Soltted Type、Phillips Type、Torx Type,Square Type,Poz

<p>Exhaust pipe Elbow...</p>